Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

EANS

-

Voltage:

-

According to requirements

-

Dimension(L*W*H):

-

20*1.5*3M

-

Power (kW):

-

80

-

Weight:

-

5000 KG

-

Product Name:

-

PVC Marble Sheet Making Machine/UV Marble Wall Panel Extrusion Machine

-

Motor:

-

Siemens China

-

Inverter:

-

ABB

-

Electric brand:

-

Schneider

-

Temperature control:

-

Omron or RKC

-

Speed:

-

3 - 10 m/min

-

Cooling way:

-

water cooling

-

Machine type:

-

PVC Profile Making Machine

-

Automaitc Grade:

-

Automatic

-

Key words:

-

UV marble sheet extrusion machine

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

2500 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

EANS

-

Voltage:

-

According to requirements

-

Dimension(L*W*H):

-

20*1.5*3M

-

Power (kW):

-

80

-

Weight:

-

5000 KG

-

Product Name:

-

PVC Marble Sheet Making Machine/UV Marble Wall Panel Extrusion Machine

-

Motor:

-

Siemens China

-

Inverter:

-

ABB

-

Electric brand:

-

Schneider

-

Temperature control:

-

Omron or RKC

-

Speed:

-

3 - 10 m/min

-

Cooling way:

-

water cooling

-

Machine type:

-

PVC Profile Making Machine

-

Automaitc Grade:

-

Automatic

-

Key words:

-

UV marble sheet extrusion machine

PRODUCT SPECIFICATIONS

SJ80/156 PVC UV Marble Wall Panel Sheet Extrusion Making Machine/UV Marble Sheet Production Line

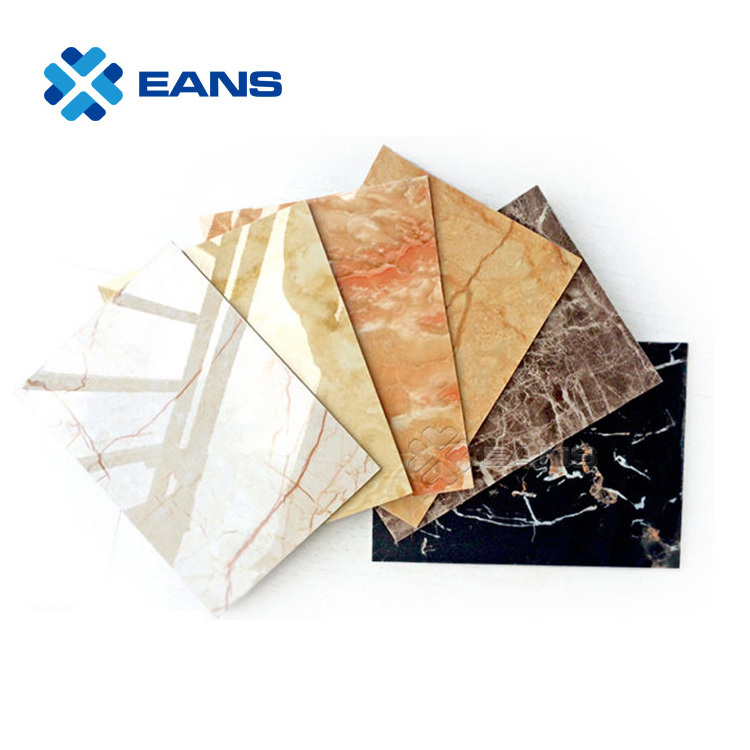

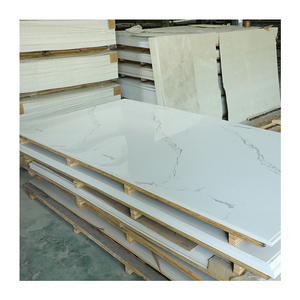

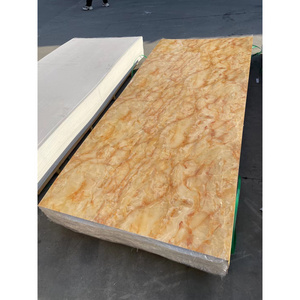

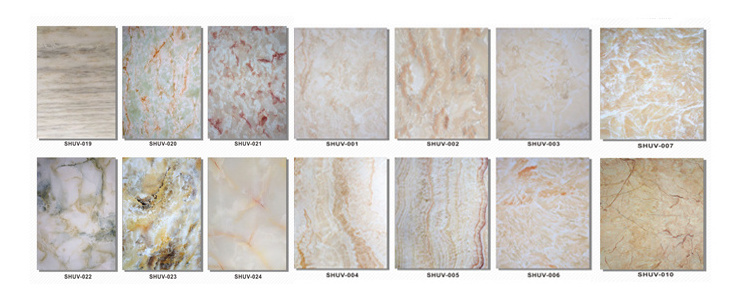

PVC UV marble sheet production line / making machine from Eans Machinery is advanced in skill and high automation. The based material extrusion, wood grain embossing, color film, wear-resisting film. By changing lamination paper, PVC lamination marble sheet can be made in SPC vinyl flooring making machine.

Extrusion mold

Adopts high quality materails, the thickness of marble wall panels are adjustable

Cooling bucket with edge cutting unit

Main advantage of Eans PVC UV marble sheet production line / making machine :

1.The screw adopt the design of special mixing material function and high plasticization capacity. This guarantee the uniformity of plastic mleting,coloring and high output.

2.Clothes rack type mold die adopt double throtting design,which can make more precision of adjusting of flooring thickness.

3.The ±1℃ precision degree of temperature control can control the plasticization process, thickness and surface smooth of sheet accurately.

4.The roller position can be put by vertical or horizontal, which can give more selection basing on the different thickness of sheet

5.The screw adjusting and oil pressure press-roller double direction adjusting can control the thickness of sheet accurately.

1.The screw adopt the design of special mixing material function and high plasticization capacity. This guarantee the uniformity of plastic mleting,coloring and high output.

2.Clothes rack type mold die adopt double throtting design,which can make more precision of adjusting of flooring thickness.

3.The ±1℃ precision degree of temperature control can control the plasticization process, thickness and surface smooth of sheet accurately.

4.The roller position can be put by vertical or horizontal, which can give more selection basing on the different thickness of sheet

5.The screw adjusting and oil pressure press-roller double direction adjusting can control the thickness of sheet accurately.

Rigid core flooring is extruded by extruder and T-die extrusion PVC substrate,with four roller calendar, PVC wearing layer, PVC color film layer and PVC substrate, one time heating paste,embossing.

Machine list for PVC UV Marble Sheet Making Machine

|

No.

|

Machine List

|

Qty

|

|

1

|

Auto screw loader

|

1 set

|

|

2

|

SJSZ92/188 conical twin screw extruder

|

1 set

|

|

3

|

T die mold

|

1 set

|

|

4

|

Three roller calendaring machine

|

1 set

|

|

5

|

Temperature controller of three roller

|

1 set

|

|

6

|

Cooling bucket with edge cutting unit

|

1 set

|

|

7

|

Traction machine

|

1 set

|

|

8

|

Precession cutter

|

1 set

|

|

9

|

Auto stacker

|

1 set

|

Why Choose us

Formula

1 - We can free offer detailed formula for each products, please feel free SEND a INQUIRY for detailed information.

2 - We also can offer the design of workshop and product suggestion.

Installation / Debug / Training

1 - We can free offer detailed formula for each products, please feel free SEND a INQUIRY for detailed information.

2 - We also can offer the design of workshop and product suggestion.

Installation / Debug / Training

1 - We will arrange seasoned technician for installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

Quality Guarantee

1 - The equipment will be tested and run for few hours before leaving the factory, to ensure the smooth working

2 - One year warranty for plastic machine, after warranty, we offer best price of easy broken parts.

After-sales Service

1 - We offer main parts and offer other parts at the favorable price at any stage

2 - After quality guarantee, we offer technology support, online and offline guidance.

Attention:

1. More detailed information, please send inquiry to us.

2. When sending inquiry or message, please tell us your Email or WhatsApp / Wechat / Skype .etc, then our sales manager can contact you quickly.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

Quality Guarantee

1 - The equipment will be tested and run for few hours before leaving the factory, to ensure the smooth working

2 - One year warranty for plastic machine, after warranty, we offer best price of easy broken parts.

After-sales Service

1 - We offer main parts and offer other parts at the favorable price at any stage

2 - After quality guarantee, we offer technology support, online and offline guidance.

Attention:

1. More detailed information, please send inquiry to us.

2. When sending inquiry or message, please tell us your Email or WhatsApp / Wechat / Skype .etc, then our sales manager can contact you quickly.

Our customer

Our Company

Zhangjiagang Eans Machinery Co.,Ltd. specialized in plastic extrusion machine and other plastic auxiliary machine. Eans machinery is a professional manufacturing enterprise that integrates development, manufacturing, technical services and marketing. We provide factory construction, installation, commission, training and so on to customers. Eans machinery has a construction area of nearly 5000 square meters and more than 50 employees. Our factory has multiple sets of advanced production equipment: CNC knife sharpener, automatic die-engraving machine, 300T/400T/630T forging press, shot blasting machine, Spray room, etc. The machines have passed SGS, CE certification, etc.

Certificates

Production Progress

Similar Products

WPC Door Making Machine

PE WPC Profile Making Machine

PVC WPC Profiles Making Machine

WPC PVC Foam Board Making Machine

FAQ

Q1. Are you a factory or a trading company?

A1: EANS is a high-end export brand of EANS Group. We have our own factory, and many high-quality suppliers. We provide

"all-in-one solution" for all series of plastic extrusion machinery. We provide you with superior quality and guaranteed

satisfaction, you will never overpay again.

Q2. Are there other machine not listed in the catalog?

A2. EANS provides all different types of plastic extrusion solutions. If you cannot find the exact machine you are looking for,

please contact us, we will be happy to develop with you and become your long-term trustworthy Chinese factory!

Q3. Can I get free samples?

A3. EANS can send free samples. But you need to pay the cost of Express which can be reduced in the order of machine in the future.

Q4. How long will I receive the quotation?

A4. Once we know the raw material, final product dimension and the special requirements, we will provide you a detailed quotation

within 8 hours.

Q5. How do I get response quickly?

A5. If you send email, whatsApp, WeChat to contact us, we promise to reply to you within 8 hours! WhatsApp is the best and 24 hours online.

A1: EANS is a high-end export brand of EANS Group. We have our own factory, and many high-quality suppliers. We provide

"all-in-one solution" for all series of plastic extrusion machinery. We provide you with superior quality and guaranteed

satisfaction, you will never overpay again.

Q2. Are there other machine not listed in the catalog?

A2. EANS provides all different types of plastic extrusion solutions. If you cannot find the exact machine you are looking for,

please contact us, we will be happy to develop with you and become your long-term trustworthy Chinese factory!

Q3. Can I get free samples?

A3. EANS can send free samples. But you need to pay the cost of Express which can be reduced in the order of machine in the future.

Q4. How long will I receive the quotation?

A4. Once we know the raw material, final product dimension and the special requirements, we will provide you a detailed quotation

within 8 hours.

Q5. How do I get response quickly?

A5. If you send email, whatsApp, WeChat to contact us, we promise to reply to you within 8 hours! WhatsApp is the best and 24 hours online.

Hot Searches