- Product Details

- {{item.text}}

Quick Details

-

Coating:

-

TIN&TIALN

-

Place of Origin:

-

Sichuan, China

-

Carbide material:

-

Imported

-

Code:

-

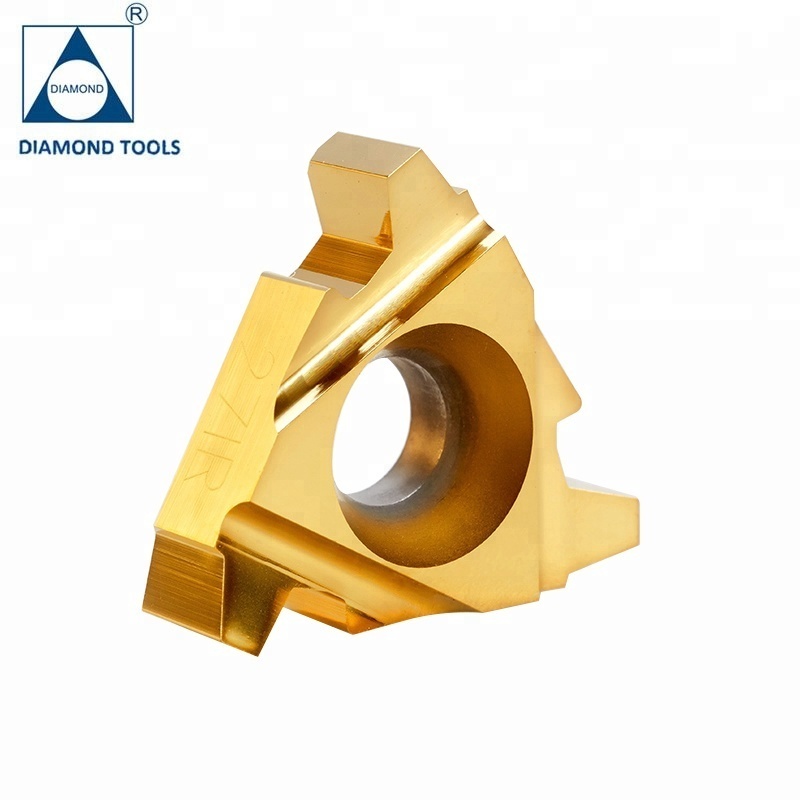

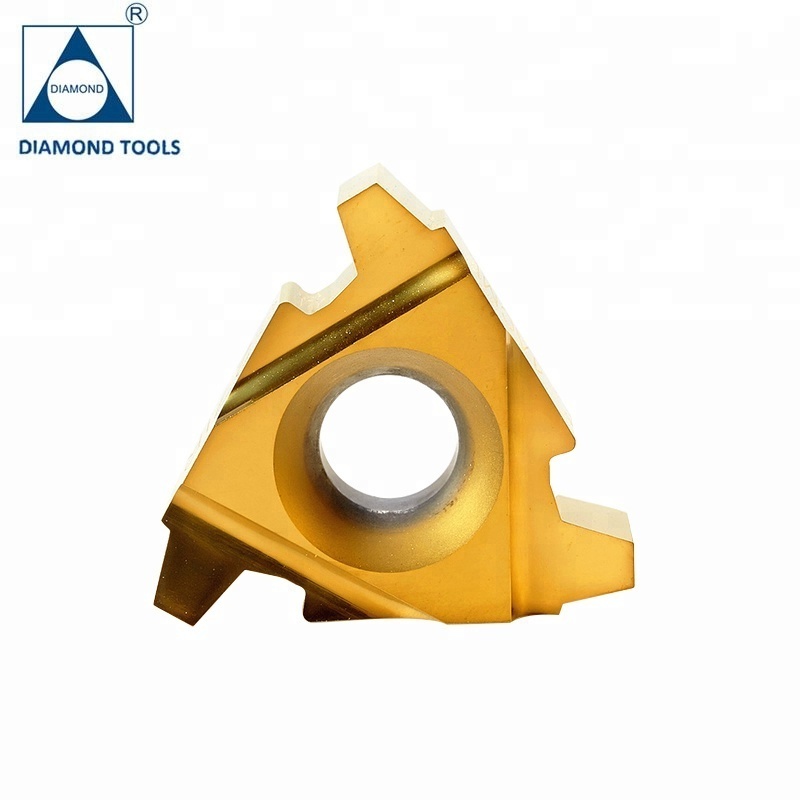

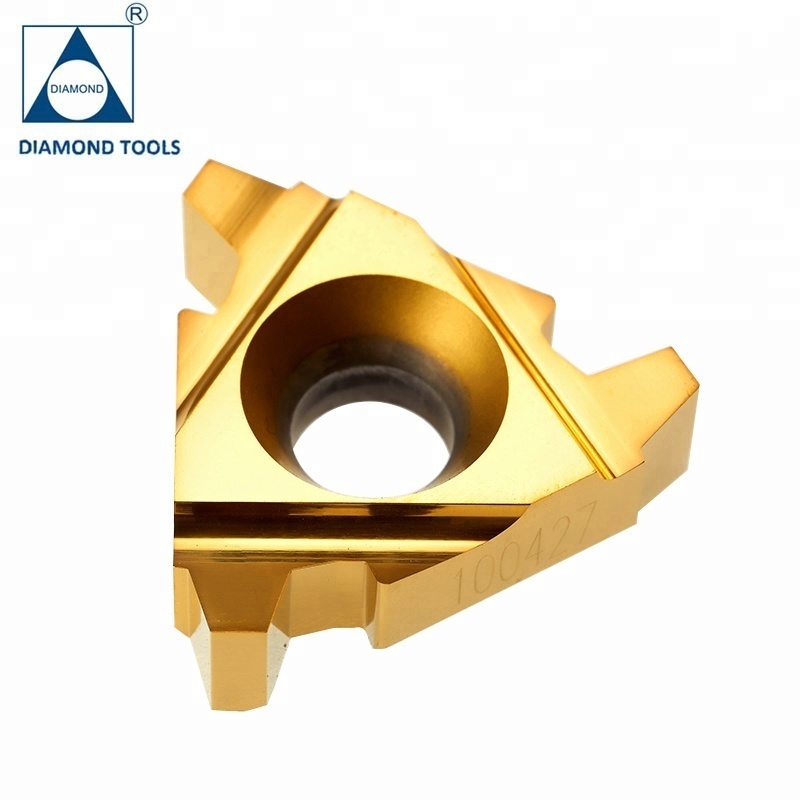

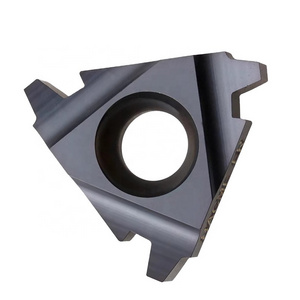

27IR4 ACME

-

Product Name:

-

ACME internal square thread inserts 27IR4 ACME

-

Testing Samples:

-

Charge FREE for a few pieces

-

OEM and ODM:

-

Acceptable

-

Place of origin:

-

Chengdu,China

-

Remarks:

-

Left hand cutting insert available

Quick Details

-

Material:

-

Tungsten Carbide

-

Usage:

-

Thread Turning Tool

-

Hardness:

-

More than 2000HV

-

Coating:

-

TIN&TIALN

-

Place of Origin:

-

Sichuan, China

-

Carbide material:

-

Imported

-

Code:

-

27IR4 ACME

-

Product Name:

-

ACME internal square thread inserts 27IR4 ACME

-

Testing Samples:

-

Charge FREE for a few pieces

-

OEM and ODM:

-

Acceptable

-

Place of origin:

-

Chengdu,China

-

Remarks:

-

Left hand cutting insert available

ACME internal square thread inserts 27IR4 ACME

1.Application : Our carbide threading inserts good for Low carbon steel, medium-carbon steel, High carbon steel, Alloy steel , Adjusting quality steel, Stainless steel, Cast steel, Cast iron,Aluminium alloy and copper alloy machining

2.Advantage Features:

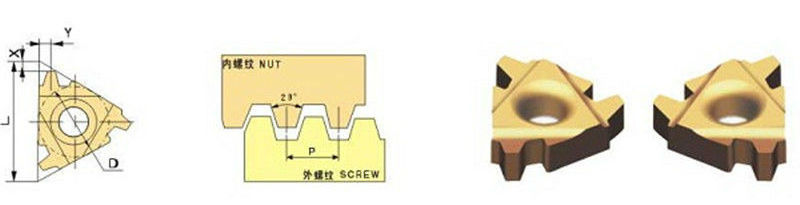

A. Full profile design ensures the precision of threads.

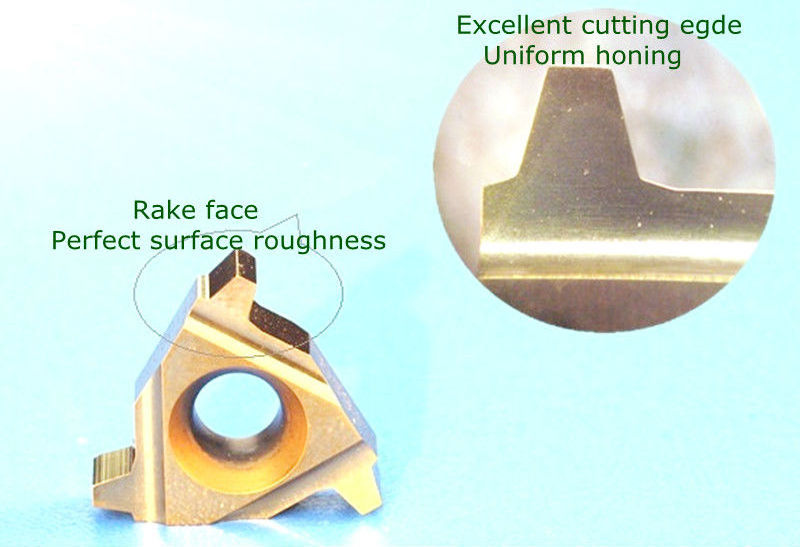

B. Rake face feature: Smooth rake face design makes the chip removal more fluency.

C. Cutting edge process feature: . Uniform horning cutting edge design ensures inserts with small cutting force .

3. Performance: Just use it and you will say yes.

4. Stock: There are always more than 50,000pcs standard inserts in stock for urgent shipment.

5. Test samples: A few pcs free samples for your test.

6. Delivery: Within 5days shipment by international express DHL, UPS, FEDEX, TNT,DPEX and EMS.

Specificatons:

| D | Pitch | Designation | Dimension | ||||

| TPI | Right Hand | Left Hand | L | X | Y | ||

| External | 3/8" | 16 | 16ER16 ACME | 16EL16 ACME | 16 | 1.0 | 1.1 |

| 14 | 16ER14 ACME | 16EL16 ACME | 1.0 | 1.2 | |||

| 12 | 16ER12 ACME | 16EL12 ACME | 1.1 | 1.2 | |||

| 10 | 16ER10 ACME | 16EL10 ACME | 1.3 | 1.3 | |||

| 8 | 16ER8 ACME | 16EL8 ACME | 1.4 | 1.5 | |||

| 1/2" | 6 | 22ER6 ACME | 22EL6 ACME | 22 | 1.8 | 2.1 | |

| 5 | 22ER5 ACME | 22EL5 ACME | 2.0 | 2.3 | |||

| 5/8" | 4 | 27ER4 ACME | 27EL4 ACME | 27 | 2.4 | 2.7 | |

| Internal | 3/8" | 16 | 16IR16 ACME | 16IL16 ACME | 16 | 1.0 | 1.1 |

| 14 | 16IR14 ACME | 16IL16 ACME | 1.0 | 1.2 | |||

| 12 | 16IR12 ACME | 16IL12 ACME | 1.1 | 1.2 | |||

| 10 | 16IR10 ACME | 16IL10 ACME | 1.3 | 1.3 | |||

| 8 | 16IR8 ACME | 16IL8 ACME | 1.4 | 1.5 | |||

| 1/2" | 6 | 22IR6 ACME | 22IL6 ACME | 22 | 1.8 | 2.1 | |

| 5 | 22IR5 ACME | 22IL5 ACME | 2.0 | 2.3 | |||

| 5/8" | 4 | 27IR4 ACME | 27IL4 ACME | 27 | 2.4 | 2.7 | |

Enlarged view of Cutting Edge:

Flow chart:

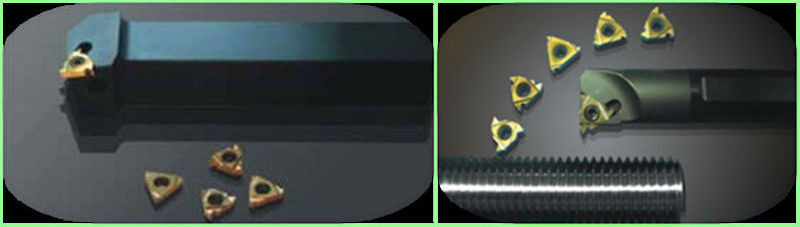

Matched Tool Holder of Inserts:

Machining Parameters :

|

Be processed material |

M30(m/min) |

P30(m/min) |

|

Low carbon steel or medium-carbon steel |

80-130 |

80-140 |

|

High carbon steel |

60-110 |

60-120 |

|

Alloy steel or Adjusting quality steel |

60-110 |

60-120 |

|

Stainless steel |

60-100 |

|

|

Cast steel |

60-110 |

60-120 |

|

Cast iron |

60-200 |

|

|

Aluminium alloy or copper alloy |

90-280 |