Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customer demand

-

Dimension(L*W*H):

-

25*1.5*1.8m

-

Power (kW):

-

45

-

Weight:

-

18000

-

Screw Speed (rpm):

-

100 - 1400 rpm

-

Raw material:

-

plastic

-

Color:

-

Client's Requirements

-

Machine:

-

PVC Pelletizer Line

-

HS code:

-

84779000

-

Max. Capacity:

-

100-800KG/H

-

Marketing Type:

-

New Product 2024

Quick Details

-

Output (kg/h):

-

100 - 300 kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CGY

-

Voltage:

-

customer demand

-

Dimension(L*W*H):

-

25*1.5*1.8m

-

Power (kW):

-

45

-

Weight:

-

18000

-

Screw Speed (rpm):

-

100 - 1400 rpm

-

Raw material:

-

plastic

-

Color:

-

Client's Requirements

-

Machine:

-

PVC Pelletizer Line

-

HS code:

-

84779000

-

Max. Capacity:

-

100-800KG/H

-

Marketing Type:

-

New Product 2024

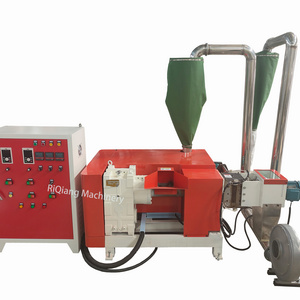

Plastic Pipe/Sheet/Profile/Granule/Pellet Making Recycling Pelletizing Plastic Extruder Machine

Waste plastic automatic compaction warehouse water granular production line, mainly for PP, PE plastic film (PP/PE film, PP/PE plastic bags, PE plastic film mulching films shed, PP woven bag bag tons of cement bags, PP nonwoven) cleaned to granulation , make plastic granular is appearance, the pellet full, even and without porosity, suitable for all kinds of waste plastic regeneration granulation recycling .

1.Conveyor&Metal detector: Detect metal in the films or bags, protect the blades of cutting compactor and screws,convey the films or bags into compaction warehouse

2.Compaction warehouse: Compaction warehouse integrate with crush, compaction, agglomeration.

3.Long screw extruder: 38CrMoAlA with nitriding processing

4.Hydraulic change nets equipment: U sing plug board type to change nets and keep machine working.The mould is made by 40Cr nitridation .The pressure sensor prompts to change the nets.

5.Short screw extruder: 38CrMoAlA with nitriding processing

6.Pelletizer: Two type----Water-ring Pelletizing Machine or Braces particle cutting machine

7.Dewatering Machine: Applicable to pieces of plastic, granules cleaning, dewatering. High dehydration degree, the dehydration rate above 95%, less consumption, and efficiency, a high degree of automation, greatly reduce the labor intensity. Dehydration clean, can remove the dopant sand in the plastic. Advanced technology,convenient clean,low noise.

8.Fan drying machine: Through the double channels strong wind dryer,force drying and cooling article material reach the fast speed effect of shaping up to .