Various connectors customizable to fit into different control systems and meet requirement of different scenarios.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FH-B

-

Brand Name:

-

Flomarvel

-

Connection:

-

NPT BSP thread, socket welding

-

Pressure:

-

PN16

-

Usage:

-

Equipment and system automation

-

Coil connection:

-

35cm (13'') lead wires

-

Certificate:

-

IP67, CE, RoHS, NSF61

-

Acting Mode:

-

On/off

-

Brand:

-

Flomarvel

-

Seal Material:

-

Silicone rubber

-

Valve seat:

-

PTFE

-

Manual override:

-

Optional

Quick Details

-

Port Size:

-

1/2'' - 2''

-

Warranty:

-

14 months

-

Place of Origin:

-

Tianjin, China

-

Model Number:

-

FH-B

-

Brand Name:

-

Flomarvel

-

Connection:

-

NPT BSP thread, socket welding

-

Pressure:

-

PN16

-

Usage:

-

Equipment and system automation

-

Coil connection:

-

35cm (13'') lead wires

-

Certificate:

-

IP67, CE, RoHS, NSF61

-

Acting Mode:

-

On/off

-

Brand:

-

Flomarvel

-

Seal Material:

-

Silicone rubber

-

Valve seat:

-

PTFE

-

Manual override:

-

Optional

Product Overview

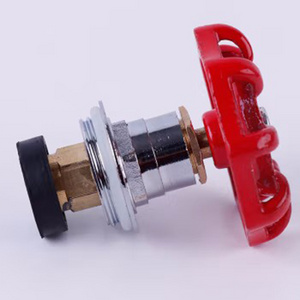

FH-B

15NM electric actuator ball valve

Electric ball valve, which is also searched as electrically actuated ball valve, motorized ball valve, motor actuator ball valve . It mainly composed of an electric motor actuator on the top and a ball valve at the bottom. These 2 parts are connected by connecting boards and screws. The electric ball valve actuators contains a motor rotates at high speed after powered on, it outputs low rotary torque which is converted to low speed high rotary torque to drives the valve open/close .

The motor actuator of FH-B series electric ball valve outputs quarter-turn rotation, which suits most of the ball valves. Thanks to the international ISO5211 standard, ball valve with ISO5211 F03/F05 mounting pad could directly assemble with the motor actuator by bolts and screws. And this allows both the electric actuator and ball valve to be swapped out with another one using the same flange size. It makes maintain and repair much easier.

So generally, no matter it is a 2 way ball valve or a 3 way ball valve, no matter it is brass, stainless steel or PVC plastic ball valve, as long as the working angle of a ball valve is typically 90 degrees, the output torque of the actuator is enough to drive to ball valve, and the ball valve has F03/F05 mounting pad, the actuator could be assembled with the ball valve to actuate the ball valve.

The electric motorized ball valve is used for automatic remote control in so many senarios, such as water treatment equipment, automatic equipment and system, home automation, HVAC system, irrigation system, wildfire emergency sprinkler system, recreational vehicle (RV), trailer home, sprinkler truck, fire truck etc. We have various control wirings and different power supply voltages for option.

Features

∎

Precision metal gear, high strength, reliable performance, long service life

∎

Multiple wiring for remote control and valve status feedback to intelligent control unit

∎

With visual position indicator and manual override for sudden power failure or unexpected emergency operate

∎

ISO5211 standard flange connection - F03, F05 - for valve and actuator connection

∎

IP 67 protection, applicable for humid environment

∎

Two auxiliary limit switches for accurate and consistent valve position

PVC electric ball valve

Electric ball valve actuator

Stainless steel motorized ball valve

Product Paramenters

|

Series

|

Torque

|

Operating Time

|

Working Voltage

|

Working Current

|

Max. Power

|

Max. Pressure

|

|

FH-B

|

15NM

|

<5s

|

5V DC,12V DC, 24V DC

|

<300mA

|

22W

|

1.6 Mpa

|

|

Medium Temperature

|

Ambient Temperature

|

Humidity

|

Enclosure

|

Service Life

|

Wiring

|

|

0-100℃/

32-212℉

|

-20-45℃/

-4 -113℉

|

95%

|

IP67

|

80,000 Times

|

OP01, OP02, OP03, OP04, OP05 Optional, Customization Available

|

Wiring diagram

OP01 Wiring - 2 Wires, Reverse Polarity

1.Connects red wire to positive pole, black wire to negative pole, the electric ball valve opens.

2.Reverse polarity, the electric ball valve closes.

※ Once in position, there will be no power consumption.

※ In case of power loss, valve will remain in its current state.

※ Voltage of power supply for option:5V DC/12V DC/9-35V DC

※ A DPDT switch is suggested for a simple set up.

OP02 Wiring - 3 Wires, 2 Points Control

1. Connects red wire to positive pole, black wire to negative pole, the ball valve opens.

2. Connects green wire to positive pole, black wire to negative pole, the ball valve closes.

※ Once in position, there will be no power consumption.

※ In case of power loss, valve will remain in its current state.

※ Voltage of power supply for option:

5V DC/12V DC/9-35V DC

※ A SPDT switch is suggested for a simple set up.

OP03 Wiring - 3 Wires, 1 Point Control

1. Connects red wire and green wire to positive pole, black wire to negative pole, the ball valve opens.

2. Disconnects green wire, the ball valve closes.

※ Once in position, there will be no power consumption.

※ In case of power loss, valve will remain in its current state.

※ Voltage of power supply for option:5V DC/9-24V ADC

※ A on/off switch can be installed in line with green wire for a simple set up.

This op03 electric ball actuator uses a constant power and ground wire while a third green wire is used for the control switch to open and close the valve.

OP04 Wiring - 2 Wires,Auto Return / Fail Safe

1. Connects red wire to positive pole, black wire to negative pole, the ball valve opens (the ball valve is normally closed by default).

2. Disconnect either wire (the circuit is open), there is no power supply to the ball valve, the ball valve closes.

※ Once in position, there is a nominal power consumption to keep the capacitor charged.

※ In case of power loss, valve will return to its normal position, which by default is normally closed valve. If normally open ball valve is needed, please let us know when place an order.

※ Voltage of power supply for option:5V DC/9-24V ADC

※ A on/off switch can be installed in line with red wire for a simple set up.

OP05 Wiring - 5 Wires,With Valve Position Feedback

1. There should be 2 power supply, one for electric ball valve actuator - red wire to positive pole, black wire to negative pole; another one for customer’s position indication devices - the green wire outputting fully-open signal connects to one device, the yellow wire outputting fully-closed signal connects to another device, and the devices both should be connected to the positive pole of the power supply, and the white wire of the electric ball valve actuator connects to negative pole of the power supply, there conforms a closed circuit. The valve opens, the open position indication device receives the fully-open signal, will light up if lights are used as position indication devices.

2. Reverse polarity, the ball valve closes, the close position indication device receives the fully-closed signal, will light up if lights are used as position indication devices.

※ Once in position, there will be no power consumption for electric ball valve, nomial power consumption for position indication devices.

※ In case of power loss, valve will remain in its current state.

※ Voltage of power supply for option:5V DC/12V DC/24V DC

※ A DPDT switch is suggested for a simple set up.

Purchase Guide

The ball valve electric actuator is assembled with ball valve by ISO 5211 standard flange pad (F03, F05). Before purchasing, make sure the output torque is enough to drive the valve, the valve is quarter-turn valve and the valve has a F03/F05 mounting pad. Below form lists the voltage and wiring available, and manual override is optional too.

Factory

Flomarvel Technology Co., ltd (Tianjin Huayi Chenlong Technology Co., Ltd) has been specialized in the R&D and production of electric ball valve/motorized ball valve for more than 10 years. Our products are mainly exported to Canada, the United States, German, Sweden, Netherlands etc. And they are mainly used in equipment and system automation, smart home, building automation, municipal water supply etc. We have rich experience providing OEM service for customer to build their own product and ODM service to customize product according to customer’s project requirements. Welcome to contact us about your needs.

“Details matter” Is our culture. We serve our customers well by doing each small thing and each valve well.

Successful Project

For Fire Extinguishing System

Automatic Equipment

Water Leakage Detection System

FAQ

1

. Is OEM/ODM service available?

As a manufacturer, we have rich experience providing OEM service for customer to build their own product and ODM service to customize product according to customer’s project requirements. Welcome to contact us about your needs.

2.

How many days is the lead time?

For standard products, when the order quantity is less than 50pcs, the lead time would be about 3 working days; when the order quantity is 50-200 pcs, the lead time would be 7 working days, for 200-1000pcs order, it would be 15 working days.

3. How do you do the shipment?

Our products are mostly shipped by express, such as UPS, DHL, Fedex etc. If the shipment could be done with cilent's courier account as payer, or

the shipment is to be done by clients' own forwarder,

then of course no freight charge. Otherwise, we could quote for the shipping cost, if it is acceptable to clients, then we can do the shipment.

For bulky order, surely we could also check the cost of shipment by air or by sea.

4. What is the MOQ?

Actually we don't have requirement about the MOQ, because for most clients, they would need to test sample first, which could be 2 pcs.

Hot Searches