- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

According to client's requirement

-

Dimension(L*W*H):

-

1060x1060x4000mm

-

Weight:

-

0.14 KG

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Name:

-

Spiral Chute

-

Material:

-

Fiberglass Reinforced Plastic

-

Color:

-

As client's requirement

-

Capacity:

-

1-40TPH

-

Usage:

-

Separating gold

-

Installation:

-

Under Engineer's Guide

-

Model:

-

Depends on the capacity

-

After sale service:

-

Whole using life

-

Certification:

-

ISO9001:2015

Quick Details

-

Production Capacity:

-

90%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Voltage:

-

According to client's requirement

-

Dimension(L*W*H):

-

1060x1060x4000mm

-

Weight:

-

0.14 KG

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Name:

-

Spiral Chute

-

Material:

-

Fiberglass Reinforced Plastic

-

Color:

-

As client's requirement

-

Capacity:

-

1-40TPH

-

Usage:

-

Separating gold

-

Installation:

-

Under Engineer's Guide

-

Model:

-

Depends on the capacity

-

After sale service:

-

Whole using life

-

Certification:

-

ISO9001:2015

Professional Mining Machine Spiral Sluice Spiral Chute

Product Introduction of High capacity mining Gravity Spiral Chute Drawing

Spiral separator is a new gravity separation machine. With the water and action of gravity friction force, minerals would be separated by the different gravity and get heavy, middling and light products.

Spiral concentrator is made of the fiberglass lined with wear-resistant polyurethnane and corundum cover, with feature of anti corrosion, rust and wear resistant.

It's the most suitable equipment for mining and ore beneficiation, especially for placer mining at seaside, riverside, sand bank and stream bank. It is of low water consumption, small floor area, high concentration and recovery ratio, high adaptability, etc

Product Application of High capacity mining Gravity Spiral Chute Drawing

It's applicable to metal and non-metal ores with adequate density difference, like iron, chromite, pyrite, tin ore, tungsten, tantalum, niobium, gold ore, colliery, monazite, rutile and Zirconium.

It can easily adopt to different raw material size, density, ore grade and feed volume. Spiral chute is suitable for treatment of 0.6-0.03mm lode and placer, but high mud content is bad for separation. At present, spiral chute has been widely used in the treatment of iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside placer and gold ore.

Main Features of High capacity mining Gravity Spiral Chute Drawing

1. Reasonable structure and small occupation area.

2. High recovery, high efficiency, and precise separation

3. Non-required power

4. anti corrosion, rust and wear resistant

5. Simple installation and Minimum maintenance requirements.

6. Low operating cost and long working life.

7. Strong adaptability to fluctuation of feeding amount, density, size and grade

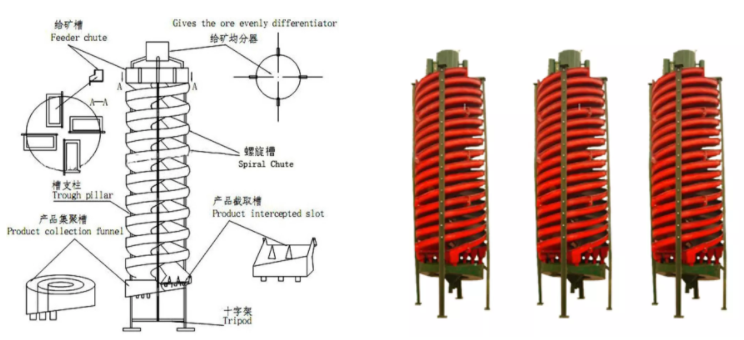

Working Principle of High capacity mining Gravity Spiral Chute Drawing

Raise the spiral chute, calibrate the vertical line, fix it in the appropriate position with iron frame or wood, send the ore to the top of the spiral feed by the sand pump, add the supplementary water, adjust the concentration of the ore paddle, the natural paddle Swirl from high to low, generating an inertial centrifugal force in the rotating bevel flow rate. Separating the ore from the sand by the gravity and centrifugal force of the swirling flow, the difference in the specific gravity, grain size and shape of the ore. The flow into the concentrate bucket is taken out by the pipeline, and the tail sand flows into the sand pond with the pipeline, and then drained by the sand pump to complete the whole process of the beneficiation.

1 00% brand new when leaving the factory.The seller guarantee quality of the machines for a period of one year from the date of trial run finish,but not to exceed twenty months from date on which machines arrive at the port of destination.If any parts(excluding easily damaging parts) are found defective in quality in the first year,the seller should replace free-of-cost .After one year,parts can be replaces on favorable payment basis.

♣ We are manufacturer of 21 years experiences, not dealer.

♣ We devote to create the biggest value with least cost for customers.

♣ We have a professional team to ensure your best pre-sale service, sale-service and after-sale service.