- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

sanjuyuan

-

Model Number:

-

q235, q355

-

Application Fields:

-

Steel Structural Fabrication Construction

-

Color:

-

Any color

-

Surface treatment:

-

Galvanized or painted

-

Main frame:

-

Solid H-shape Steel Beam

-

Purlin:

-

C.Z Shape Steel

-

Roof and Wall:

-

Sandwich Panel , Corrugated Steel Sheet , daylight panel

-

Window:

-

PVC Steel or Aluminum Alloy

-

Door:

-

as per your requirement

-

Drawing design:

-

customer's requirement or we supply

-

Installation:

-

Quick assembly

Quick Details

-

Grade:

-

steel

-

Tolerance:

-

±1%

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

sanjuyuan

-

Model Number:

-

q235, q355

-

Application Fields:

-

Steel Structural Fabrication Construction

-

Color:

-

Any color

-

Surface treatment:

-

Galvanized or painted

-

Main frame:

-

Solid H-shape Steel Beam

-

Purlin:

-

C.Z Shape Steel

-

Roof and Wall:

-

Sandwich Panel , Corrugated Steel Sheet , daylight panel

-

Window:

-

PVC Steel or Aluminum Alloy

-

Door:

-

as per your requirement

-

Drawing design:

-

customer's requirement or we supply

-

Installation:

-

Quick assembly

|

If you need

|

|

|

|

|

||||

|

|

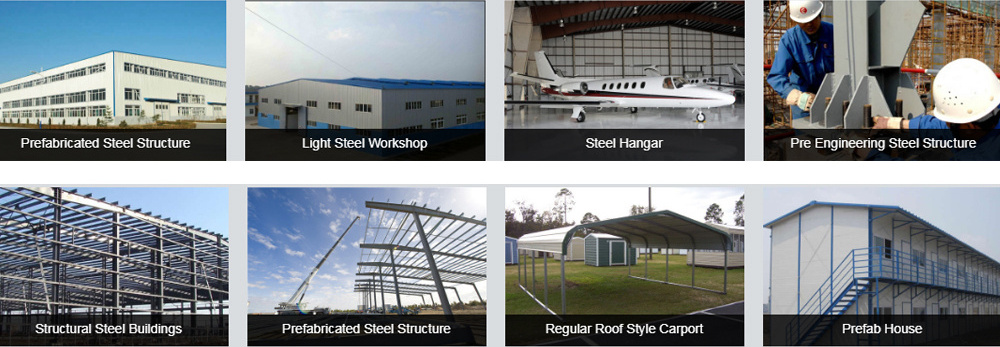

1) Steel Structure Building

|

|

|

|

||||

|

|

2) Steel Structure Warehouse

|

|

|

|

||||

|

|

3) Workshop / Factory

|

|

|

|

||||

|

|

4) Metal Building

|

|

|

|

||||

|

|

5) Modular House

|

|

|

|

||||

|

|

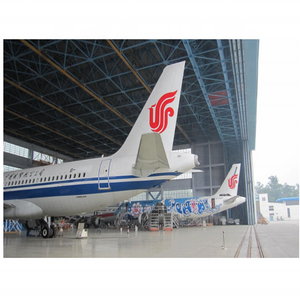

6) Garage/Hangar

|

|

|

|

||||

|

|

7) Steel beams other riveting and welding parts

|

|

|

|

||||

|

|

8)Poultry farm/Cow shed/Horse shed

|

|

|

|

||||

|

We can provide you

|

|

|

|

|

||||

|

Different Sizes

|

Width X Length X Eave height.

|

|

|

|

||||

|

Different Types

|

Single slope,double slope, Single span,double-span,Multi-span Single floors, Double floors.

|

|

|

|

||||

|

Material

|

Material Q345(S355JR) or Q235(S235JR) steel, all bolt connections. Straight cross-section or Variable cross-section.

|

|

|

|

||||

|

Different Purlins

|

C or Z type: Size from C120~C320, Z100~Z200

|

|

|

|

||||

|

Different roof /wall panel

|

Single colorfull corrugated steel sheet or sandwich panel with EPS, ROCK WOOL, PU etc.

|

|

|

|

||||

|

All Accessories

|

Semi-transparent skylight belts, Ventilators, down pipe, Galvanized gutter, etc

|

|

|

|

||||

|

Surface

|

Two layers of Anti-rust Paint!

|

|

|

|

||||

|

Design parameters

|

|

|

|

|

||||

|

|

1) Live load on roof (KN/M2)

|

|

|

|

||||

|

|

2) Wind speed (KM/H)

|

|

|

|

||||

|

|

3) Snow load (KG/M2) - If Applicable

|

|

|

|

||||

|

|

4) Earthquake load - If Applicable

|

|

|

|

||||

|

|

5) Style of Doors and Windows

|

|

|

|

||||

|

|

6) Crane (if you have), Crane span, Crane lift height, max lift capacity, max wheel pressure and min wheel pressure

|

|

|

|

||||

|

|

7) Size: width X length X eave height, roof slope

|

|

|

|

||||

|

|

8) Or your idea!

|

|

|

|

||||

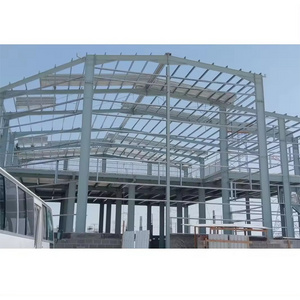

Products Description

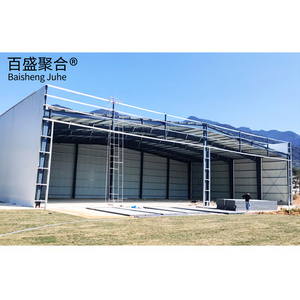

10x12 sheds storage outdoor frame building aircraft hangar car parking steel structure barn build kit

Compared with the traditional concrete structure building system, the light steel structure building projects have a series of advantages, such as large span, low demands of base structure, strong seismic and wind resistance, beautiful appearance, shorter construction cycle, strong corrosion resistance, non-polluted, low maintenance costs and so on. Therefore it is more and more popular with the customers. It is mainly used for large-span structures, workshops, warehouses, office buildings, large supermarkets, logistics warehouses, showrooms, hangar, etc.

|

Product Name

|

Easy assemble pre fab building light I steel fabricate steel warehouse steel structures

|

|

|

|

|||

|

Material

|

Q235 Q355/S355

|

|

|

|

|||

|

Main Structure

|

H steel

|

|

|

|

|||

|

Purlin

|

C&Z steel

|

|

|

|

|||

|

Roof and Wall

|

a) Color-coated corrugated steel sheet;

b) Rock Wool Sandwich Panels; c) EPS Sandwich Panels; d)Glass wool Sandwich Panels |

|

|

|

|||

|

Door

|

a)Rolling Gate;

b) Sliding door |

|

|

|

|||

|

Window

|

PVC Steel or Aluminum Alloy

|

|

|

|

|||

|

Downspout

|

Round pvc pipe

|

|

|

|

|||

|

Usage

|

All kinds of industrial workshop, warehouse, supermarket, high-rise building, etc

|

|

|

|

|||

CHARACTERISTICS

Easy assemble pre fab building light I steel fabricate steel warehouse steel structures

1. Environmental friendly

2. Low cost and maintenance

3. Long using time up to 50 years

4. Stable and earthquake resistance up to 9 grade

5. Fast construction, time saving and labor saving

6. Good appearance

7. Easy assembly and disassembly several times without damage

2. Low cost and maintenance

3. Long using time up to 50 years

4. Stable and earthquake resistance up to 9 grade

5. Fast construction, time saving and labor saving

6. Good appearance

7. Easy assembly and disassembly several times without damage

PRODUCT PHOTOS

Easy assemble pre fab building light I steel fabricate steel warehouse steel structures

is beam&column&purlin&Roof&wall panel. The connection of it 10.9s high strength bolt. The roof and wall purlin is connected with the beam with bolts. Roof and wall panel is connected with purlin with self tapped screw. Few parts will use welding connection. This connection is more easier for installation and also stable for the whole building. Steel structure building has the advantage of lightweight and easy assembly. so it is mainly used as big warehouse, workshop, storage shed, poultry farm house, steel hangar house, GYM, swimming pool.etc

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Materials Cost

Construction and material costs for traditional structures are much more expensive than a prefabricated steel or metal buildings,and as a result ,our products are more cost effective.

Quick Assembly

Pre-fabricated steel structures arrives at the construction site in ready-to-assemble sections.All you have to do is lay it out and about it together.As most kits arrive with all components included,they are simple to assemble and provide massive savings on labor and material costs.

Accurate Design

Metal and steel building templated are engineered,generated and manufactured using computer technology.

Improved Flexibility,Design and Portability

Prefab steel buildings are expandable and manufacturers are also very flexible and accommodating to design and engineer custom plan for you project,offering you more freedom in the design and layout of your building.In addition,you can simply add another section to the steel building if you need more space or disassemble the it and more it with you if need to be in another location.

.

Construction and material costs for traditional structures are much more expensive than a prefabricated steel or metal buildings,and as a result ,our products are more cost effective.

Quick Assembly

Pre-fabricated steel structures arrives at the construction site in ready-to-assemble sections.All you have to do is lay it out and about it together.As most kits arrive with all components included,they are simple to assemble and provide massive savings on labor and material costs.

Accurate Design

Metal and steel building templated are engineered,generated and manufactured using computer technology.

Improved Flexibility,Design and Portability

Prefab steel buildings are expandable and manufacturers are also very flexible and accommodating to design and engineer custom plan for you project,offering you more freedom in the design and layout of your building.In addition,you can simply add another section to the steel building if you need more space or disassemble the it and more it with you if need to be in another location.

.

Hot Searches