- Product Details

- {{item.text}}

Quick Details

-

Applicable Industries:

-

polymer compounding

-

Product name:

-

Barrel

-

For what machine:

-

EXTRIDER MACHINE

-

MOQ:

-

1set

-

Packing:

-

Wooden Case

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

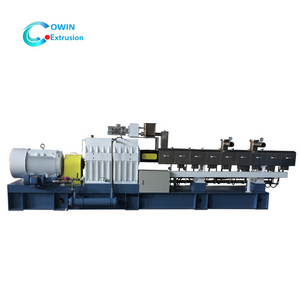

Brand Name:

-

COWIN

-

Weight (KG):

-

25

-

Applicable Industries:

-

polymer compounding

-

Product name:

-

Barrel

-

For what machine:

-

EXTRIDER MACHINE

-

MOQ:

-

1set

-

Packing:

-

Wooden Case

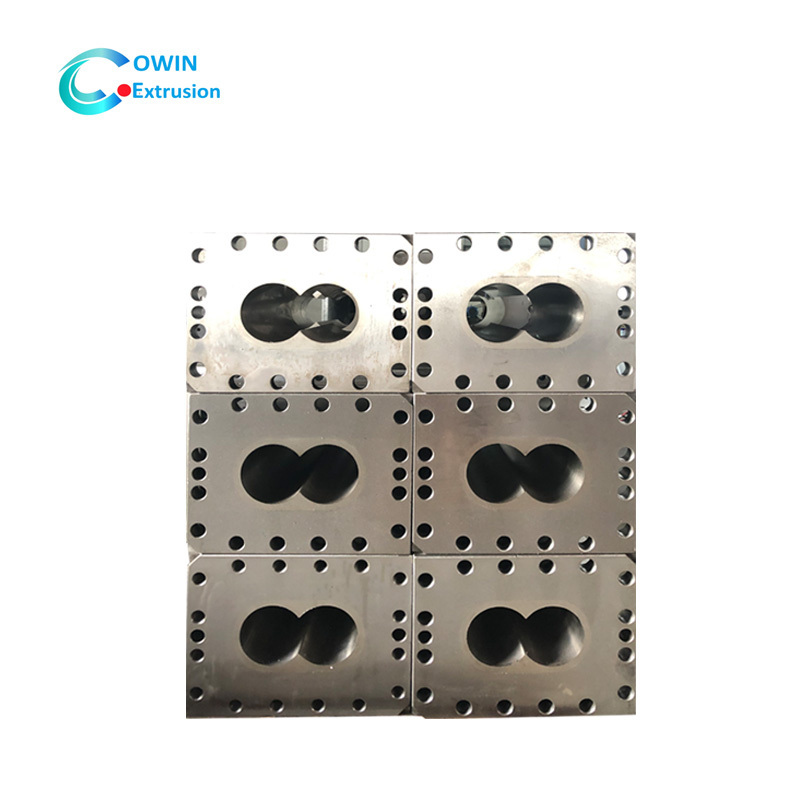

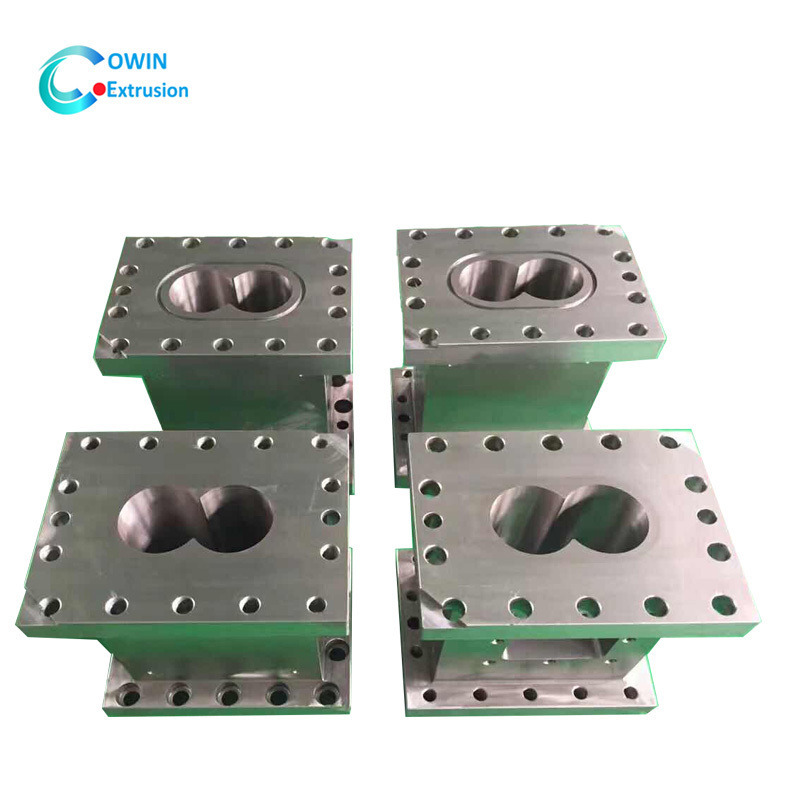

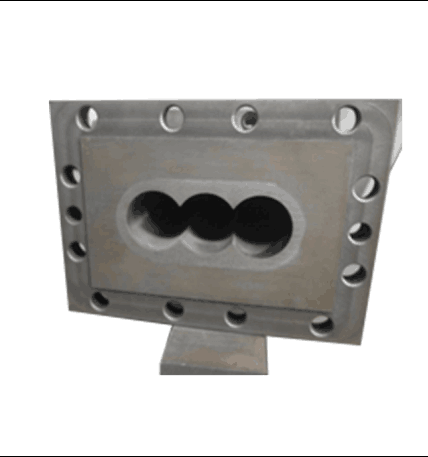

The flexible modular principle is realised with screw barrel sections from the wide range of different designs possible. The barrel sections are cooled with water, by means of an internal bore system, with bores arranged close to the inside barrel wall.

For bimeta barrels, generally we have three types of materials to provide:

(1) C-type liner

Bimetallic means the inside barrel hole made of alloy liner and outside base made of steel. Some typical elements for the liner can be:

|

material type

|

chromium

|

carbon

|

other

|

|

α 101

|

20%

|

2.5%

|

8%V

|

|

α 301

|

18%

|

2.5%

|

6% Tungsten

|

(2) Oval liner

It is made from one kind of high-chromium iron alloy (Cr12MoV), which is very famous in China these years due to its high wear resistant feature and its longer service life. We take our manufacturing process to a new level by introducing the oval liner products. We follow the unique formulation and ultimate techniques in our production that gives the best results in our supply.

(3) Imported material of world leading suppliers

For even higher wear resistance and higher corrosive resistance, we use imported material from Germany SAM26 - 26% chromium, 2.7% carbon and 3.5% V.

Modular barrels are available as follows for different processing requirements.

It is made from one kind of high-chromium iron alloy (Cr12MoV), which is very famous in China these years due to its high wear resistant feature and its longer service life. We take our manufacturing process to a new level by introducing the oval liner products. We follow the unique formulation and ultimate techniques in our production that gives the best results in our supply.

(3) Imported material of world leading suppliers

For even higher wear resistance and higher corrosive resistance, we use imported material from Germany SAM26 - 26% chromium, 2.7% carbon and 3.5% V.

Modular barrels are available as follows for different processing requirements.

We adopt horizontal CNC, and advanced processing to machine the inner hole and pin hole at one time to ensure the coaxial degree of the barrel within 0.02mm. We use the advanced 3D measuring instrument to control the tolerances of each row of the cylinder.

COWIN EXTRUSION was founded in 2012 in NANJING, Jiangsu Province. There are more than 50 people working in the company of which 5 engineers,15 people for mechanical processing and management, 20 assembling workers and 5 people for after-sales service.

COWIN EXTRUSION always focuses on R&D of new technology & products, equipment process and manufacturing, and turnkey project of high polymer related processing equipments.

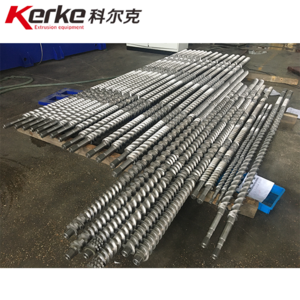

COWIN products are mainly composed:1. twin screw extruders 2. single screw extruders 3. two stage extruders 4. plastic machinery parts 5. plastic granulators 6. ancilliary

Our team has more than 20 years experience in extruder industry. We always focus on innovation during the development and we supply best quality products to customers of both China domestic and overseas.

We follow "win-win" model to support our overseas customers in Taiwan, Viet Nam, Malaysia, Indonesia, Singapore, India, Russia, Turkey, Latvia, French, South Africa, Canada, Mexico, and Brasil etc.

Pre-sales service:

1.Introducing in detail features and application of the products to customer

2.Selecting economical and practical machine & equipment for customer

3.Providing operation data of the related machine & equipment

4.Providing means of trial performance for customer

Sales service:

1.Recommending engineering conditions required for installation of the machine & equipment

2.Communicating in time the manufacturing progress of the machine with user

3.Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-service:

1.Providing on the spot technical assistance in installation, commissioning and training

2.Filing in detail customer's information

3.Providing long-term maintenance service and spare parts

4.Giving technical support to customer for developing new product

5.Providing free maintenance for a year

Packing:

The whole machine line can be divided into 4-8 wooden boxes. After applying the rust preventive oil, it is placed in a packaging film or a bubble film. Finally, Putting the machine in a wooden box and fix it with steel wire or nails.

Delivery:

10-30 days after confirming order,detail delivery date should be decided according to production season and order quantity.

1. Q: Are you a factory or trading company,How is you factory extrusion experience?

A: We are a factory. 20 years experience on extrusion.Leading supplier in Nanjing city.

2.Q: How long is your machine's guarantee time?

A: 1 year, Main parts is made of high tool steel by special quenching treatment, with high corrosion resistance and wear resistance.

3. Q:What can you provide for after sale service?

A: We provide on the spot technical assistance in installation, commissioning and training if you need.

4. Q:If we have very special request for the production line,could you help me to do the design?

A:We provide experienced mechanical designer customized-design.

5. Q: If we have samples of new products, can you help to analysis and design the machine?

A:Yes, our technical department can help you analyze, design and test the new products you offer.