- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Trihope

-

Voltage:

-

380v,220v,customized

-

Dimension(L*W*H):

-

7500x2980x1550

-

Weight (KG):

-

7600

-

Press Force:

-

500KN

-

Hole Pitch Accuracy:

-

±0.20

-

Max Punch Hole Diameter:

-

32mm

-

Max Embossing Area:

-

160x60 mm

-

Max Busbar Size:

-

6000x200x15 mm

-

Total Power:

-

14KW

-

Machine Size (LxW):

-

7500*2980 mm

-

Machine Weight:

-

7600 KG

-

Processing material:

-

Copper and Aluminum Bus Bar

Quick Details

-

Max. Thickness (mm):

-

15 mm

-

Max. Width (mm):

-

200 mm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Trihope

-

Voltage:

-

380v,220v,customized

-

Dimension(L*W*H):

-

7500x2980x1550

-

Weight (KG):

-

7600

-

Press Force:

-

500KN

-

Hole Pitch Accuracy:

-

±0.20

-

Max Punch Hole Diameter:

-

32mm

-

Max Embossing Area:

-

160x60 mm

-

Max Busbar Size:

-

6000x200x15 mm

-

Total Power:

-

14KW

-

Machine Size (LxW):

-

7500*2980 mm

-

Machine Weight:

-

7600 KG

-

Processing material:

-

Copper and Aluminum Bus Bar

1.Machine introduction

1.Machine introduction

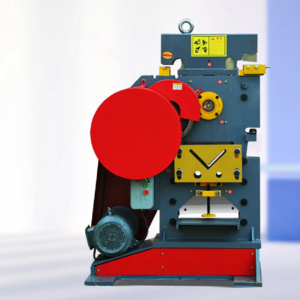

1)CNC-BP series CNC Busbar Punching and Shearing Machine is a professional high efficient and high accurate busbar processing machinery controlled by computer.

-The punching dies,shearing die, embossing die are put at the tooling library.

-The machine can finish hole punching (round hole, oblong hole etc), embossing, shearing, grooving, cutting filleted corner etc.

-The machine can realize auto rotating of clamp as for long busbar, human intervention is not needed. Thefininshed workpiece will be automatically delivered via the conveyor.

-This series machine can match with CNC bender and forn busbar processing production line.

2). Programming software

The special aided design software of busbar processing is connected with the machine and auto program is realized. User operates the software, it is convenient and fast .The software can calculate the hole punching position after bending is extended ,automatically form machine code and avoid complicated manual coding of machine language. The software can demonstrate the whole process of busbar punching, shearing and bending and prevent effectively the material waste because of input fault. Our company took the lead and applies the 3D graphic technique into the busbar processing industry, which is a great contribution to the industry and advanced technology is word class level.

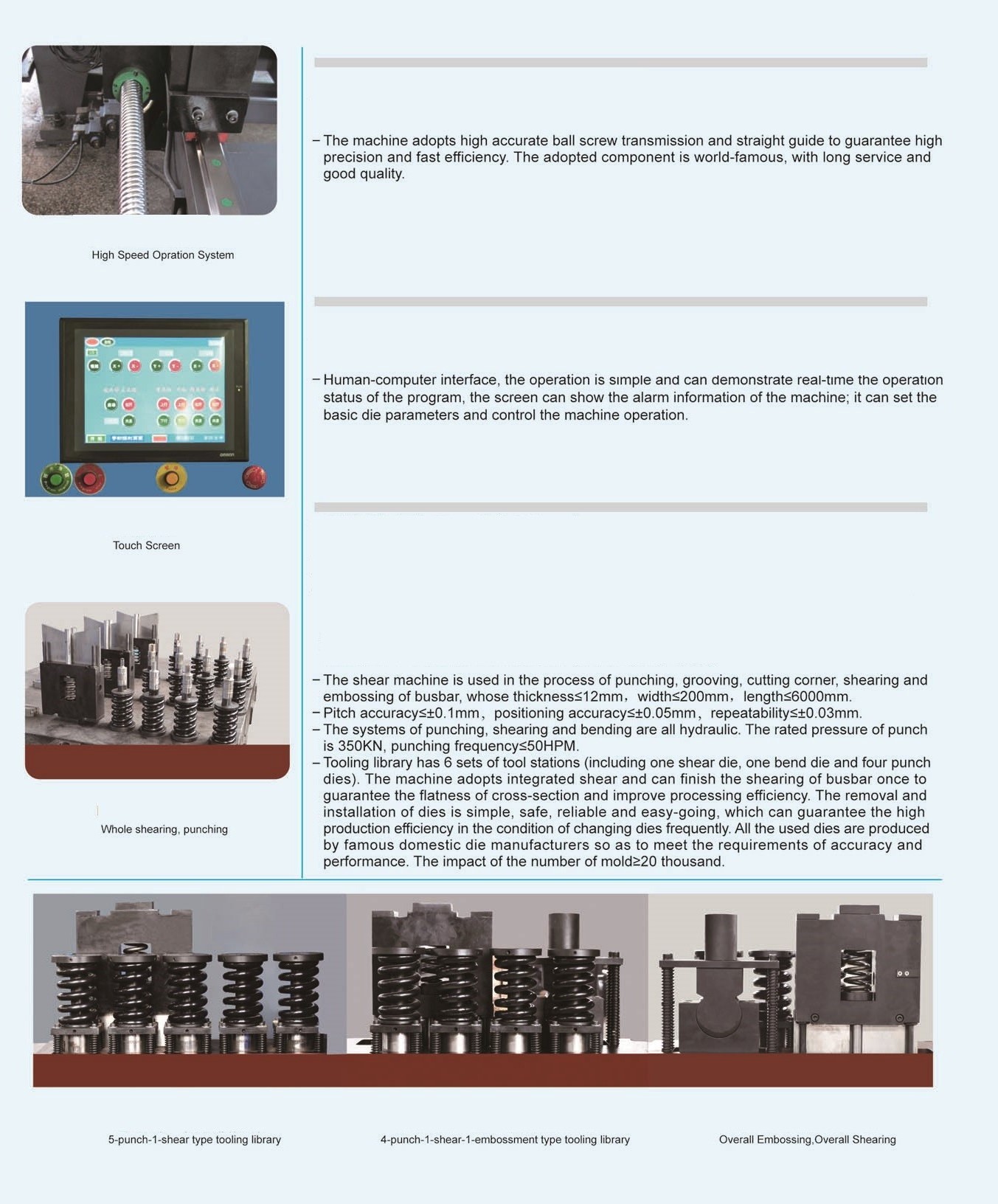

3).Touch Screen

Human-computer interface, the operation is simple and can demonstrate real-time the operation atatus of the program, the screen can show the alarm information of the machine; it can set the basic die parameters and control the machine operation.

4).Primary, Secondary Clamps

The machine adopts primary, secondary clamps structure, which can guarantee effectively the straightness of the workpiece to increase the processing accuracy;

The clamps adopt hydraulic driving technique, the structure is compact, the work is stable, no noise and no need of gas.

5).High Speed Operation System

High accurate ball screw transmission, coordinated with high accurate straight guide, high precision, fast effective, long service time and no noise.

6).Fast Conveyor

Stainless steel conveyor can guarantee no wear of the workpiece, long service reliability.

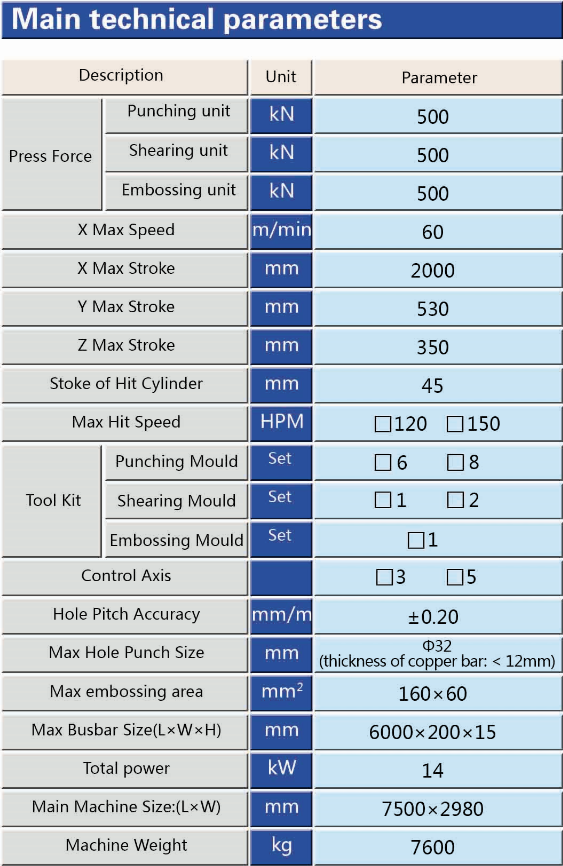

2.Main technical parameters