- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 380V

-

Power:

-

7KW

-

Dimension(L*W*H):

-

2.74*1.31*1.72m

-

Weight:

-

1600kgs

-

Paper Cup Size RANGE:

-

12-16OZ

-

Speed:

-

35-45pc/min

-

Paper cup Top Diameter:

-

Min 45mm - Max 104mm

-

Paper Cup Bottom Diameter:

-

Min 35mm - Max 75mm

-

Paper Cup Height:

-

Min 35mm - Max 140mm

-

Raw Material:

-

150~~350gsm, single or double PE coating paper

-

General Power:

-

7 Kw

-

Name:

-

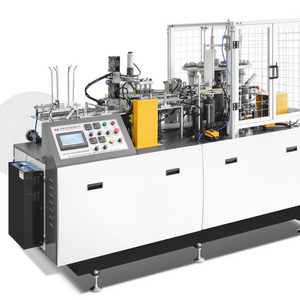

D16 Fully Automatic High Speed Double Pe Paper Cup Machine Korea Price

Quick Details

-

Production Capacity:

-

45-60pcs/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DEPAI

-

Voltage:

-

220V 380V

-

Power:

-

7KW

-

Dimension(L*W*H):

-

2.74*1.31*1.72m

-

Weight:

-

1600kgs

-

Paper Cup Size RANGE:

-

12-16OZ

-

Speed:

-

35-45pc/min

-

Paper cup Top Diameter:

-

Min 45mm - Max 104mm

-

Paper Cup Bottom Diameter:

-

Min 35mm - Max 75mm

-

Paper Cup Height:

-

Min 35mm - Max 140mm

-

Raw Material:

-

150~~350gsm, single or double PE coating paper

-

General Power:

-

7 Kw

-

Name:

-

D16 Fully Automatic High Speed Double Pe Paper Cup Machine Korea Price

850 Paper Cup Printing Machine 850 Paper Cup Die Cutting Machine

D16 Fully Automatic High Speed Double Pe Paper Cup Machine Korea Price

DP-D16 paper cup machine is an automatic machine with multi-working station,which runs a procedure of single pe coated paper cup fan feeding,cup side welding(by heater),silicone oil lubrication(for cup curling),bottom punching,bottom preheating,bottom folding,bottom knurling,top curling and cup discharging.It has the function of photocell detection,failure alarm,with the advantage of humanism design,safe operation,easy maintenance and durable running.It is an ideal equipment of making disposable paper cups for all types cups(hot and cold drink,coffee,tea,ice cream cup an so on.

|

Model Number |

D16 |

|

Paper Cup Size RANGE |

12-16 OZ |

|

Speed |

35-45 pc/min |

|

Paper cup Top Diameter |

Min 45mm-Max 104mm |

|

Paper Cup Bottom Diameter |

Min 35mm-Max 75mm |

|

Paper Cup Height |

Min 35mm-Max 140mm |

|

Raw Material |

180-350gsm, single or double PE coating paper |

|

General Power |

7 Kw |

|

Electricity |

380V 3 Phases |

|

Weight |

1600kg |

|

Measurement |

2.6m×1.22m×1.7m |

1. Paper cup bottom sealing by hot air station.

2. It is easy to make cups of different size by changing moulds.

3. Cup side sealing by ultrasonic system .

4. Double PE coating paper cups for cold drink as well as hot drink .

5. Equiped with robotic arm and 3 pillar shafts each side, which let the machine run more steady.

6. With our unique original designed single shaft bottom knurling system, this ensures the low leaking ratio and high quality of paper cups.

7. Sucker import from Taiwan, which can reach 100 million times’ life span.

8. Design with special cover, our machine is very good for heat dissipation and ensure the longer life span.

9. all the machine covers could be taken down in 2 minutes, very convenient for repair and daily maintenance.

10. We have 8 cams in the paper cup machines, while others maybe only 6 cams.

11. With automatic failure alarm sysem, when no bottom, or finished cup is over running, the machine will stop automatically.

Factory Picture