- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

0.6 T

-

Power (kW):

-

Customized

-

Product name:

-

High temperature car bottom electric forging resistance furnace

-

Application:

-

hardening and tempering

-

Chamber size:

-

Customized

-

Working temperature:

-

1400C

-

Heating element:

-

SiC rods

-

Power supply:

-

380V/50Hz-60Hz

-

OEM:

-

YES

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

SGS CE ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

SAFTHERM

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Weight (T):

-

0.6 T

-

Power (kW):

-

Customized

-

Product name:

-

High temperature car bottom electric forging resistance furnace

-

Application:

-

hardening and tempering

-

Chamber size:

-

Customized

-

Working temperature:

-

1400C

-

Heating element:

-

SiC rods

-

Power supply:

-

380V/50Hz-60Hz

-

OEM:

-

YES

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

SGS CE ISO

Furnace Chamber Material

Different furnace materials are selected according to different temperatures. We usually use ceramic fiber materials and Mullite brick material, if the use temperature is high, you can choose to use hollow ball alumina material;

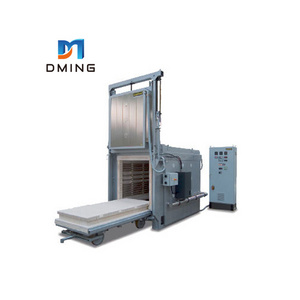

Product Application

1400℃ Car Bottom Furnace (bogie hearth furnace) products are mainly used for large materials sintering or small production application development; the furnace adopts high-quality chamber material mullite brick and large chamber constuction technology;

Bogie Furnaces (car bottom furnaces) are used for a wide range of industrial heating and heat treatment processes in small, medium and large industries. The heating can be done with different systems. Car bottom furnaces are suitable for the annealing of iron and steel, the tempering and removing of non-ferrous metals as well as the hardening. Furthermore, they are used for the baking

and sintering of ceramic applications. Thanks to its advantageous construction that allows the furnace floor to be driven out of the furnace, the car bottom furnace is accessible from all sides, which facilitates the feeding. This furnace type has been designed for a broad temperature range and is thus very versatile in use.

Bogie Furnaces (car bottom furnaces) are used for a wide range of industrial heating and heat treatment processes in small, medium and large industries. The heating can be done with different systems. Car bottom furnaces are suitable for the annealing of iron and steel, the tempering and removing of non-ferrous metals as well as the hardening. Furthermore, they are used for the baking

and sintering of ceramic applications. Thanks to its advantageous construction that allows the furnace floor to be driven out of the furnace, the car bottom furnace is accessible from all sides, which facilitates the feeding. This furnace type has been designed for a broad temperature range and is thus very versatile in use.

|

Model No.

|

STT-96-14

|

STT-288-14

|

STT-10140-14

|

||

|

Chamber size(mm)W*D*H

|

400*600*400

|

600*800*600

|

1300*1300*6000

|

||

|

Power supply

|

380V/30KW

|

380V/50KW

|

380V/1000KW

|

||

|

Max. temperature

|

1400 ℃

|

|

|

||

|

Continuous temp.

|

1300℃

|

|

|

||

|

Heating rate

|

≤ 25℃/min ( suggest 15℃/min for longer life using of furnace )

|

|

|

||

|

Accessories

|

One pair of high temperature furnace gloves; One pair of crucible stongs

|

|

|

||

|

Optional devices

|

Paperless recorderStainless steel exhaust chimney

Alumina crucible |

|

|

||

Features

1. The furnace material is mullite brick, strong and durable and does not drop powder in high temperature, heat capacity is small, energy saving above 50%

2. The heating element is made of SIC rods, which can bear large load, stable and long service life

3. The heating rate is fast, from room temperature to 1000 degrees, generally takes 15-30 minutes

4. High precision of temperature control, small temperature compensation and temperature accuracy ± 1 ° C

5. Using intelligent PID temperature control instrument, with program function, can set the temperature rise curve, can be programmed 30 segments

6. Electronic components are used Delixi products, with leakage protection, safe and reliable

7. The machine will send out an alarm signal to the over-temperature during the working process, and automatically complete the protection action.

8. When the instrument program is set, just press the run button and the next work will be completed automatically

9. Optional air inlet can be used to purge and protect the inert gas such as air. It can also be installed with an exhaust chimney and connected with stainless steel bellows to discharge the toxic and harmful gases volatilized in the furnace to the designated location.

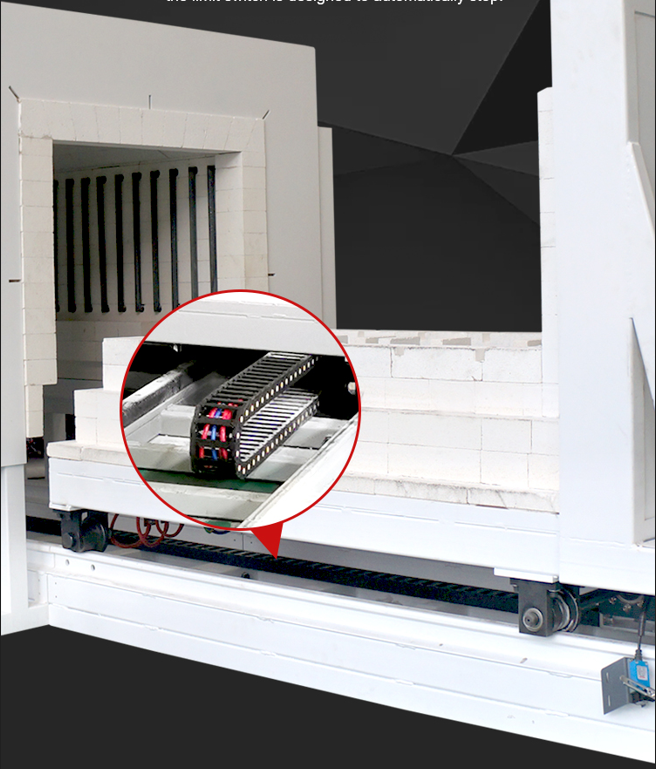

Automatic electric drive

The electric drive of thetrolley move forward or backward and the limit switch is designed to automatically stop.

M

ain Features

High standard, high quality

Heating Element

High quality Silicon Carbide Rod(SIC) heater,Excellent temperature uniformity;

Temp Controller

It can be programmed with 30 sections, and RS485 communication interface and communication software can be selected to realize remote control and data recording of the furnace;

Voltmeter And Ammeter

Accurately measure the current intensity in the circuit, with precision standard and clear scale;

Henan Sante Furnace Technology Co., Ltd. is a high-tech enterprise located in Luoyang area of Henan﹒China Free Trade Zone.SAFTHERM products cover 1000℃/1200℃/1300℃/1400℃/1600℃/1700℃/1800℃ Box furnace, Tube furnace, Vacuum furnace, High Temperature Furnace, 2000℃ Ultra-High Temperature Furnace, Dental furnace, Industrial chamber furnace, elevator furnace, Intelligent mobile car bottom furnace, Smelting furnace and so on.

Our goal is to continuously meet the various demands for various kinds of high temperature heating treatment lab furnaces and to be the world first-class enterprise with providing excellent service and high-quality products for our cooperation partners!

Henan Sante Furnace Technology Co., Ltd.

Email:

caleb.li@saftherm.com

Hot Searches