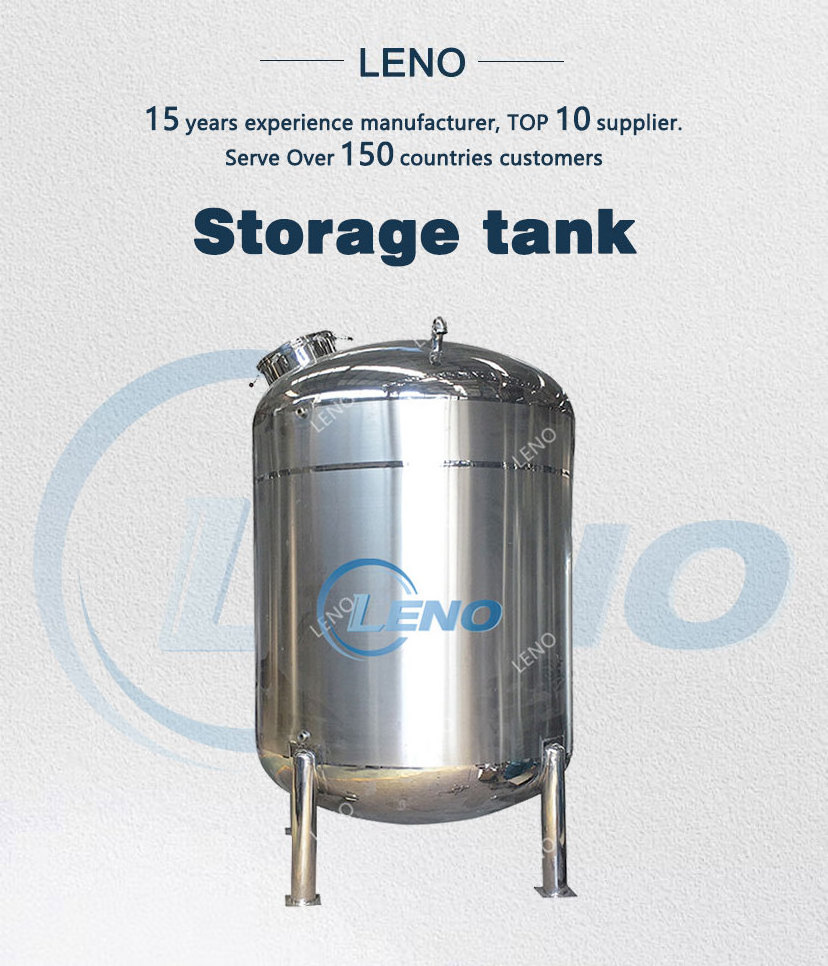

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LENO

-

Dimension(L*W*H):

-

customized

-

Weight:

-

60

-

Product name:

-

Stainless Steel Storage Tank

-

Material:

-

SS304/SS316L

-

Application:

-

Food chemical

-

Processing:

-

beverage food

-

Usage:

-

store

-

package:

-

Plywoodcases

-

capacity:

-

50L-20T

-

Size:

-

customized

-

Origin:

-

China wenzhou Lenotank

-

Volume:

-

50L-20T (Customized)

Quick Details

-

Capacity:

-

50L-20T

-

Max Working Pressure(MPa):

-

0.6 MPa

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LENO

-

Dimension(L*W*H):

-

customized

-

Weight:

-

60

-

Product name:

-

Stainless Steel Storage Tank

-

Material:

-

SS304/SS316L

-

Application:

-

Food chemical

-

Processing:

-

beverage food

-

Usage:

-

store

-

package:

-

Plywoodcases

-

capacity:

-

50L-20T

-

Size:

-

customized

-

Origin:

-

China wenzhou Lenotank

-

Volume:

-

50L-20T (Customized)

Stainless steel storage tanks are widely used in a variety of industries for storing liquids, gases, and other materials. The working process of a stainless steel storage tank can be broadly divided into three stages: filling, storage, and discharge.

Filling: The filling process involves transferring the material to be stored into the tank. This can be done through a variety of methods, such as gravity feed, pump transfer, or vacuum transfer. It is important to ensure that the material is transferred safely and without any spills or leaks.

Storage: Once the material has been transferred into the tank, it is stored until it is needed. Stainless steel tanks are preferred for storage due to their durability, resistance to corrosion, and ease of maintenance. The tank is designed to hold the material securely and prevent any leakage or contamination. The tank may also be equipped with sensors to monitor the level of the material and the temperature inside the tank.

Discharge: When the material is needed, it is discharged from the tank through a valve or pump. The discharge process must be carefully controlled to avoid any spills or leaks. It is also important to ensure that the material is discharged at the correct pressure and flow rate to prevent any damage to the equipment or process.

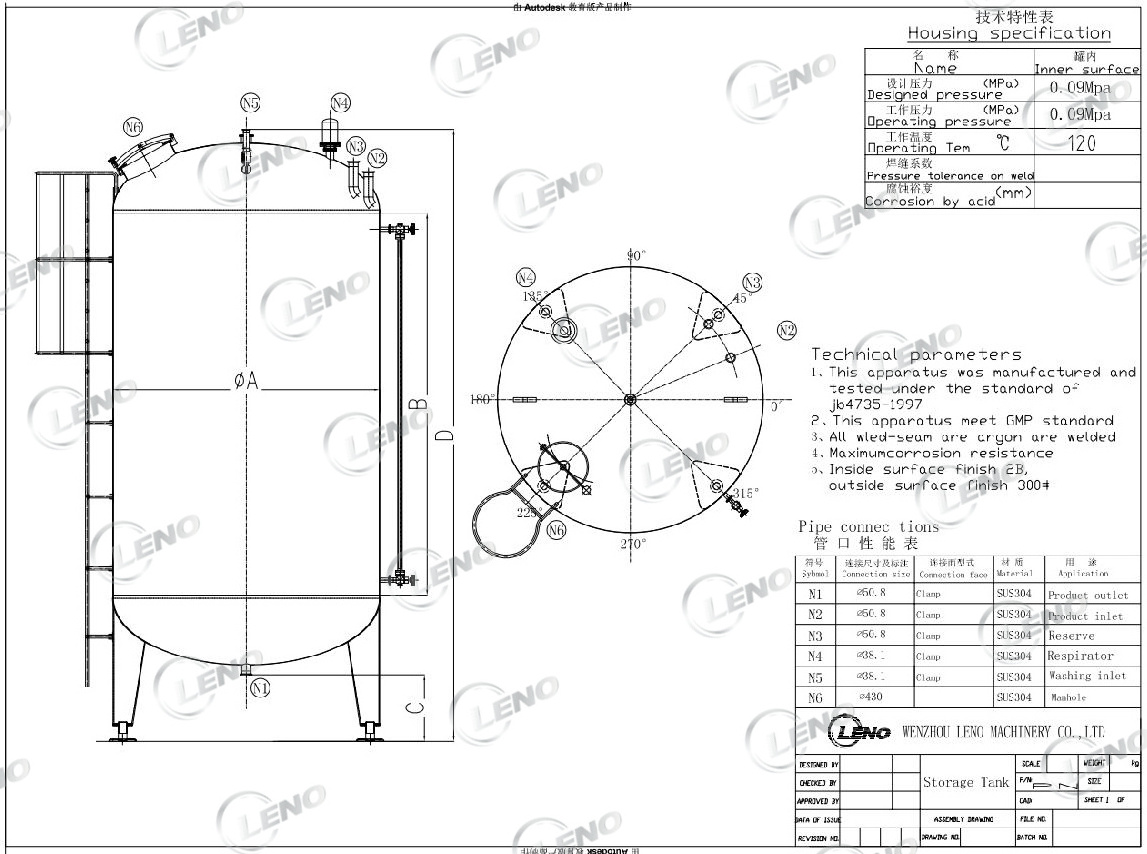

Products Description

|

Profile type

|

Single layer tank

|

Double layer tank

|

Three layer tank

|

||

|

material

|

SS304 or SS316L

|

|

|

||

|

Volume

|

50L-20T (Customized)

|

|

|

||

|

Pressure

|

Vacuum-1Mpa

|

|

|

||

|

Tank Type

|

Vertical type or Horizontal type

|

|

|

||

|

Structure

|

one layer

|

Inner layer+jacket

|

inner layer+jacket+insulation

|

||

|

Cooling way

|

No

|

ice water /cooling water

|

ice water /cooling water

|

||

|

heating way

|

No

|

electric/steam heating

|

electric/steam heating

|

||

|

Agitator type

|

No

|

low speed

|

High speed

|

||

|

|

No

|

0-200RPM

|

960-3400RPM

|

||

|

PARTS DETAILS

|

1.Quick open manhole / Pressure manhole

|

|

|

||

|

|

2.Various types of CIP cleaners

|

|

|

||

|

|

3.Sterile respirator

|

|

|

||

|

|

4.Adjustable Legs

|

|

|

||

|

|

5.Inlet and Outlet sanitary valve

|

|

|

||

|

|

6.Thermometer (According to customer requirements )

|

|

|

||

|

|

7.Paddle blender .(According to customer requirements)

|

|

|

||

|

|

8.Liquid level meter and lever controller (According to customer requirements)

|

|

|

||

|

|

9.Ladder

|

|

|

||

Product Paramenters

|

Model

|

Effective volume(L)

|

Dimension of tank (D*H)(mm)

|

Total Height(mm)

|

Motor power(kw)

|

Agitator speed(r/min)

|

|||||

|

LNT-500

|

500

|

Φ800x900

|

1700

|

0.55

|

|

|||||

|

LNT-1000

|

1000

|

Φ1000x1200

|

2100

|

0.75

|

|

|||||

|

LNT-2000

|

2000

|

Φ1200x1500

|

2500

|

1.5

|

|

|||||

|

LNT-3000

|

3000

|

Φ1600x1500

|

2600

|

2.2

|

|

|||||

|

LNT-4000

|

4000

|

Φ1600x1850

|

2900

|

2.2

|

|

|||||

|

LNT-5000

|

5000

|

Φ1800x2000

|

3150

|

3

|

|

|||||

|

LNT-6000

|

6000

|

Φ1800x2400

|

3600

|

3

|

|

|||||

|

LNT-8000

|

8000

|

Φ2000x2400

|

3700

|

4

|

|

|||||

|

LNT-10000

|

10000

|

Φ2100x3000

|

4300

|

5.5

|

|

|||||

|

We can customize the equipment according to customer requirements.

|

|

|

|

|

|

|||||

Product Image

Recommend Related Products

Various kinds of the mixers showing

LENO magnetic agitator is

a type of mixing equipment that uses a magnetic field to rotate a magnetic stir bar inside a container. The stir bar is typically made of a magnetic material, such as PTFE -coated neodymium, and is placed inside the container along with the material being mixed.

LENO paddle mixer

is a type of mixing equipment used in various industries to blend dry powders, granules, and other solid materials. The mixer consists of a large, rotating agitator, called a paddle, that moves the material around inside the mixer. The paddles are typically shaped like wings or blades, and they move the material in a tumbling motion, creating a gentle yet effective blending action.

LENO anchor agitator

is a type of mixing equipment used in various industrial applications to blend viscous liquids and pastes. The agitator consists of a central shaft with several blades, or anchors, attached to it. The anchors are typically flat, rectangular or trapezoidal in shape, and are positioned perpendicular to the shaft. As the shaft rotates, the anchors move the material around in a scraping motion, creating a mixing action that ensures thorough blending of the ingredients.

LENO scraped wall agitator

is a type of mixing equipment used in various industrial applications to blend high viscosity materials, such as creams, gels, pastes, and ointments. The agitator consists of a central shaft with several blades, or scrapers, attached to it. The scrapers are typically rectangular or trapezoidal in shape, and are positioned parallel to the shaft. As the shaft rotates, the scrapers move along the wall of the mixing vessel, scraping off the material and ensuring that it is thoroughly mixed.

LENO high shear mixer

is a type of mixing equipment used in various industrial applications to blend and emulsify

materials. The mixer consists of a rotor and stator assembly, which work together to create a high shear force that breaks down particles and blends the material into a uniform mixture.

materials. The mixer consists of a rotor and stator assembly, which work together to create a high shear force that breaks down particles and blends the material into a uniform mixture.

LENO propeller agitator

is a type of mixing equipment used in various industrial applications to blend low to medium viscosity liquids. The agitator consists of a central shaft with several blades, or propellers, attached to it. The propellers are typically flat, curved, or angled in shape, and are positioned perpendicular to the shaft. As the shaft rotates, the propellers create a flow pattern that circulates the material and blends it together.

LENO dispersing mixer

is a type of mixing equipment used in various industrial applications to disperse, homogenize and deagglomerate materials. The mixer consists of a rotor-stator assembly, which works together to create a high shear force that breaks down particles and blends the material into a uniform mixture.

LENO spiral mixer is a type of mixing equipment used in commercial bakeries and food processing industries for mixing dough. The mixer has a unique design that uses a spiral-shaped dough hook to mix the ingredients together.

LENO spiral mixer is a type of mixing equipment used in commercial bakeries and food processing industries for mixing dough. The mixer has a unique design that uses a spiral-shaped dough hook to mix the ingredients together.

Hot Searches