- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2023

-

Voltage:

-

220/380/400/415V

-

Dimension(L*W*H):

-

1950*900*1950mm

-

Motor Power (kW):

-

3

-

Weight (T):

-

1.2

-

function:

-

Channel steel, Angle steel, I-beam steel, etc.

-

Round bar:

-

40mm

-

Angle iron:

-

120x120x12

-

Punching:

-

31x12mm

-

Flat iron:

-

Cutting function 140#

-

Product name:

-

Iron cutting machine

-

Machine Type:

-

Iron Working Machine

-

Type:

-

Multi-Function Machine

-

Usage:

-

Cutting and punching metal products

-

Power:

-

Electric

Quick Details

-

Nominal Force (kN):

-

360

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HONGYIN

-

Year:

-

2023

-

Voltage:

-

220/380/400/415V

-

Dimension(L*W*H):

-

1950*900*1950mm

-

Motor Power (kW):

-

3

-

Weight (T):

-

1.2

-

function:

-

Channel steel, Angle steel, I-beam steel, etc.

-

Round bar:

-

40mm

-

Angle iron:

-

120x120x12

-

Punching:

-

31x12mm

-

Flat iron:

-

Cutting function 140#

-

Product name:

-

Iron cutting machine

-

Machine Type:

-

Iron Working Machine

-

Type:

-

Multi-Function Machine

-

Usage:

-

Cutting and punching metal products

-

Power:

-

Electric

Product details

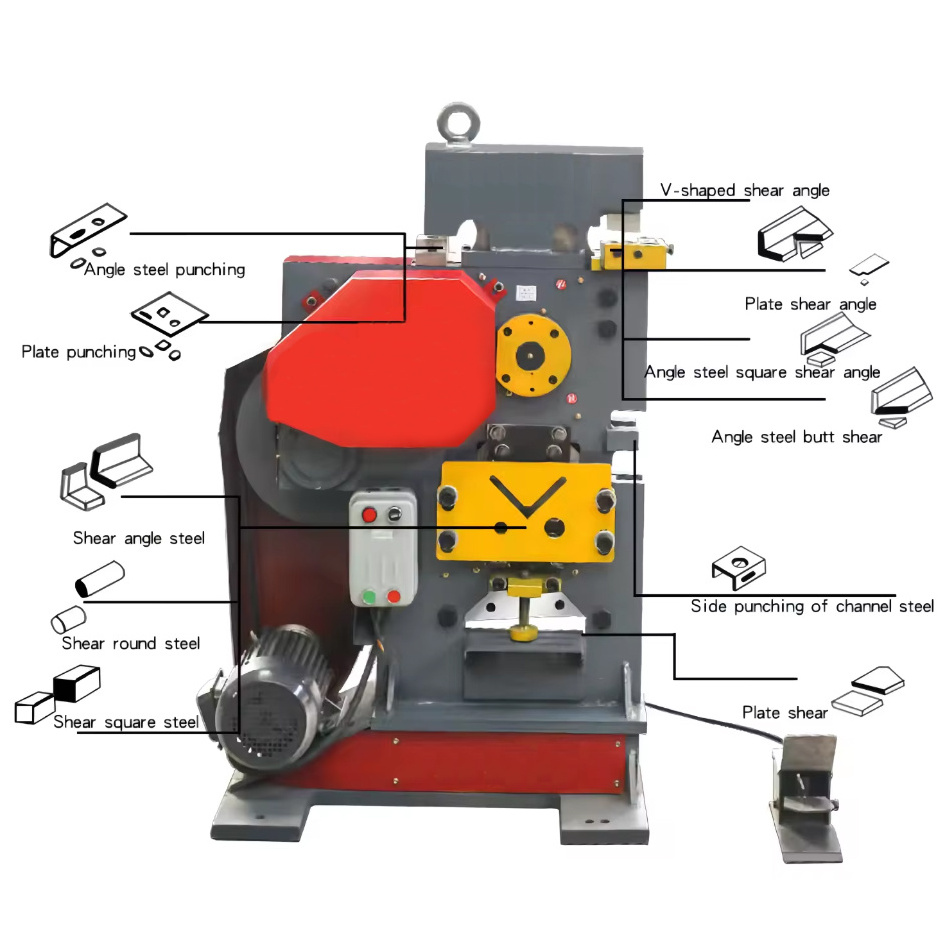

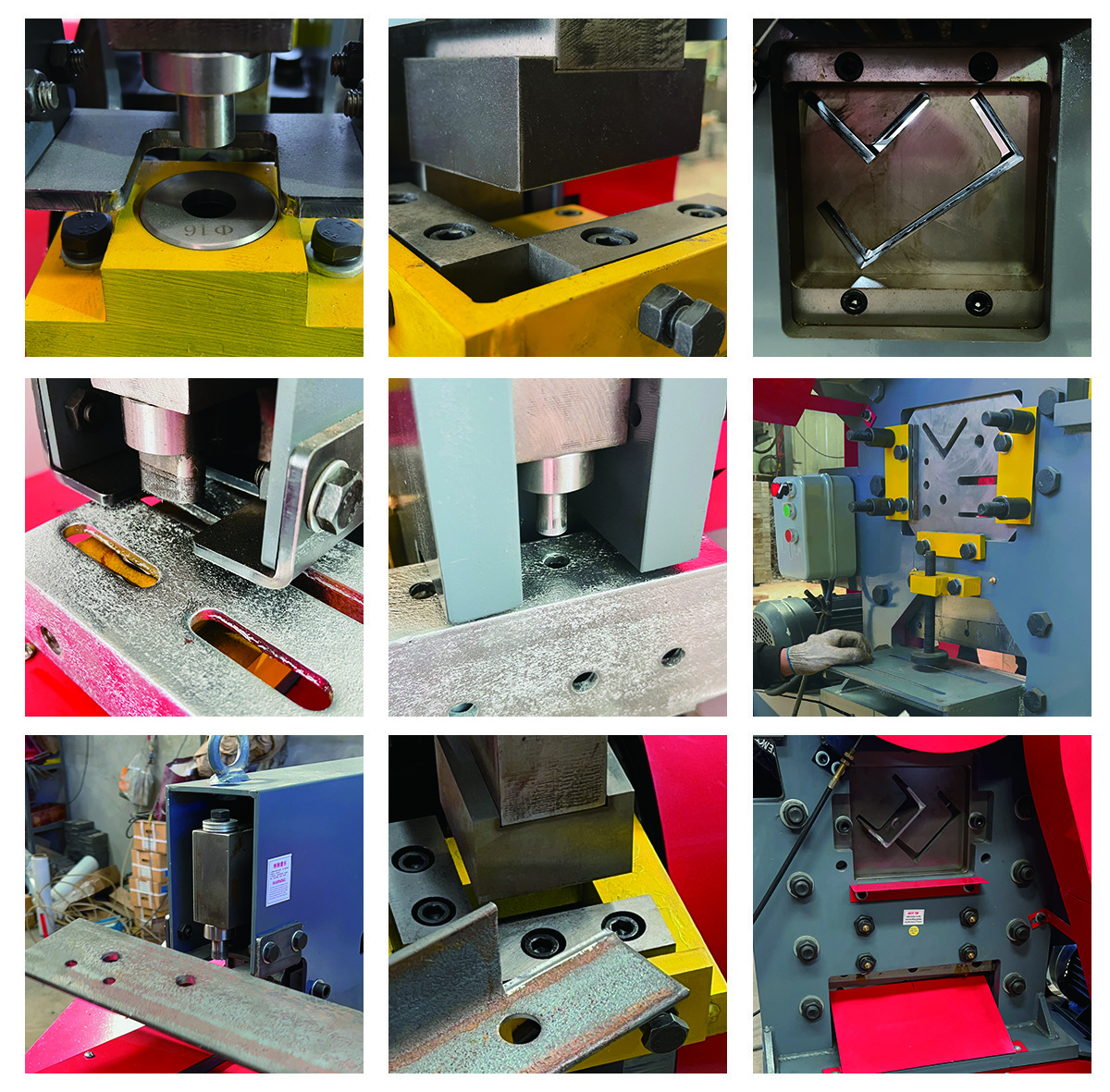

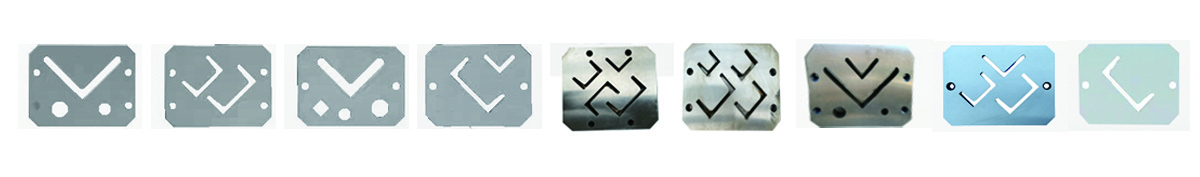

Mold display

Main functions and features

Combined punching and shearing machine is a machine tool equipment integrating multiple functions such as metal shearing, punching, plate shearing and bending. It has the advantages of simple operation, low energy consumption and low maintenance cost. It is the preferred equipment for metal processing in modern manufacturing industries (such as metallurgy, bridge, communication, electric power and so on). Combined punching and shearing machine is divided into hydraulic combined punching and shearing machine and mechanical combined punching and shearing machine.

Technical Parameters

| Model | QA32-8B | QA32-10B | QA32-12B | QA32-14B |

| Pressure | 360KN | 500KN | 900KN | 1200KN |

| Mold stroke | 27MM | 30MM | 36MM | 36MM |

| Stamping speed | 30 time/min | 30 time/min | 30 time/min | 25 time/min |

| Total power | 2.2KW | 3.0KW | 4.0KW | 5.5KW |

| Weight | 450KW | 710KG | 950KG | 1300KG |

| Form factor | 900*600*1100mm | 900*600*1200mm | 700*1100*1450mm | 740*1180*1550mm |

| Package size | 1000*680*1240mm | 1000*680*1460mm | 750*1200*1600mm | 830*1250*1680mm |

| Cut corner steel | MAX 75*75*8mm | MAX 100*100*10mm | MAX 125*125*12mm | MAX 150*150*14mm |

| Grooved steel | MAX 8# | MAX 12# | MAX 16# | MAX 20# |

| Cut flat steel | MAX 180*8mm | MAX 230*10mm | MAX 330*12mm | MAX 330*14mm |

| Punching thickness | MAX 8mm | MAX 10mm | MAX 12mm | MAX 14mm |

| Cut round bars | MAXΦ30mm | MAXΦ35mm | MAXΦ40mm | MAXΦ40mm |

| Voltage | 220V/380V/400V/415V | |||

| Voltage frequency | 50/60HZ | |||

| HS | 8462490000 | |||

Product Packaging & Shipping

Workshop

Our service

Pre-sales services:

1. inquiry and consulting support

2. sample testing support

3. visit our factory

Aftersales services:

1. 1 years warranty period

2. training how to install and use the brake press machine

3. engineers available to service machinery overseas

FAQ

1.What about the payment term&price term?

As usual, we accept T/T as the payment term, and the price term FOB is ok.

2.Are you a trading company or a factory?

Xingtai Hongyin Manufacturing Co., Ltd. is a manufacturer in Hebei Province, China. We specialize in punching and shearing machines and hoop bending machines for more than 10 years, and our high-quality products are welcomed by many countries.

3.How do you make your price?

We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture.You will get competitive price and better quality.

4.How about the packing?

Outside Package: Wooden packing case as export standard ; Inside Package: Stretch film.

5. What's the delivery time?

Usually, we will delivery the goods within 15-20 working days, but this is aim at 1-10 pieces products, if more quantity, it depends.

6. Questions before quotation?

Capacity? Lifting height? Voltage? Quantity? The more details the more accurate price quotation. Thank you.

7.what about our mechanical features?

(1) Compact structure and reasonable design

(2) Easy to install, operate and maintenance

(3) Low noise and good working condition

(4) Three-phase power supply, suitable for a wide range of applications

(5) Simple structure, easy to identify the cause of the failure, easy to repair and maintain