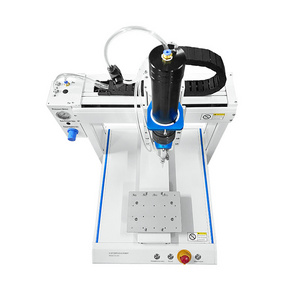

The desktop type PCBA router I.C.T-100A uses the high-speed rotating spindle to cut automatically. It provides a high-performance, high safety and high stability industrial equipment platform (high-precision integrated motion control card, stepping motor, precision slide rail) with simple operation, fast cutting speed and high accuracy, with the high-intensity dust collection system, keep PCBA and working surface clean.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

I.C.T-100A

-

Product name:

-

Desktop Model PCBA Router

-

Pcb Size(Special size optional):

-

280*300mm

-

PCB thickness:

-

0.3~4.0mm

-

Weight(with vacuum cleaner):

-

85 kg

-

Dimension:

-

600*500*500mm

-

Dust Collection Method:

-

Vacuum cleaning

-

Air volume of vacuum cleaner:

-

12~20cm3/min

-

Vacuum cleaner Dimension:

-

860*470*730mm

-

Voltage of the Dust Collector:

-

380V,50/60HZ, 1.2kw

Quick Details

-

Weight (KG):

-

85

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

I.C.T

-

Model Number:

-

I.C.T-100A

-

Product name:

-

Desktop Model PCBA Router

-

Pcb Size(Special size optional):

-

280*300mm

-

PCB thickness:

-

0.3~4.0mm

-

Weight(with vacuum cleaner):

-

85 kg

-

Dimension:

-

600*500*500mm

-

Dust Collection Method:

-

Vacuum cleaning

-

Air volume of vacuum cleaner:

-

12~20cm3/min

-

Vacuum cleaner Dimension:

-

860*470*730mm

-

Voltage of the Dust Collector:

-

380V,50/60HZ, 1.2kw

Product Description

Factory Price High Precision Pcba Router Machine Separator Desk Automatic Jet Dispensing Machine

Manual PCB V-cut Machine

1, The cutting stress is smaller, so as to prevent chips such as ceramic capacitors from being damaged in the cutting process.

2, It can cut straight line, arc and other shapes on PCBA substrate, so the constraint on substrate design is greatly reduced.

3, Using high speed spindle, cutting stress is greatly reduced, precision is high, inertia is small, and response is fast.

4, High cutting precision, smooth cutting surface, to meet the needs of customers for high-quality production process.

5, The separated vacuum dust collector adopts high efficiency motor with high suction and low noise.

6, Humanized operation system design, simple operation, flexible.

2, It can cut straight line, arc and other shapes on PCBA substrate, so the constraint on substrate design is greatly reduced.

3, Using high speed spindle, cutting stress is greatly reduced, precision is high, inertia is small, and response is fast.

4, High cutting precision, smooth cutting surface, to meet the needs of customers for high-quality production process.

5, The separated vacuum dust collector adopts high efficiency motor with high suction and low noise.

6, Humanized operation system design, simple operation, flexible.

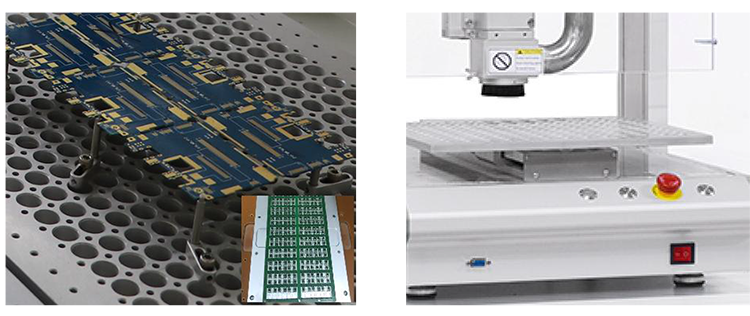

1. Adopt the top dust collection design, equipped with anti-static brush adsorption, ensure the PCBA surface clean.

2. Equipped with high-power dust collector, low noise, strong adsorption capacity, flexible installation.

1. Standard platform and special fixture platform can be installed to meet different requirements of PCBA.

2. Machine closed structure, prevent dust leakage, teaching box operation, simple, humanized design concept.

2. Machine closed structure, prevent dust leakage, teaching box operation, simple, humanized design concept.

Specification

|

PCB Router

|

I.C.T-100A

|

|

Pcb Size(Special size optional)

|

280*300mm

|

|

PCB thickness

|

0.3~4.0mm

|

|

PCB support mode

|

Multifunctional fixture, special fixture

|

|

X、Y Cutting Speed

|

0~100mm/s

|

|

Repeat Precision

|

± 0.01mm

|

|

X、Y、Z Driving Method

|

Step motor

|

|

Operation

|

Teaching box

|

|

Cut Precision

|

± 0.1mm

|

|

Rotational Speed of the Main Shaft

|

Max 40000rpm

|

|

Router Voltage

|

220V,50/60HZ

|

|

Power Supply

|

1.0kw

|

|

Weight(with vacuum cleaner)

|

85kg

|

|

Dimension

|

560*600*650mm

|

Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of electronic industry experience, through our superior resources in China to provide global customers with systematic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customers to set up factories in LED, TV, mobile phone, DVB, EMS and other industries all over the world.

We are trustworthy.

Our Advantages

Exhibition

Packing & Delivery

※ Standard Wooden Case with Vacuum Package

Shipping Way:

※ By air, for sample and small package, international express like DHL, UPS, EMS...

※ By sea, for large package and quantity;

※ Other ways as customer requested.

Delivery Time:

※ Within 35 Days.

※ By air, for sample and small package, international express like DHL, UPS, EMS...

※ By sea, for large package and quantity;

※ Other ways as customer requested.

Delivery Time:

※ Within 35 Days.

FAQ

|

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner |

|

Q: Are you a trade company or manufacturer?

A: Full SMT machines maufacturer for smt line in China; OEM & ODM service are available. |

|

Q: What is your delivery date?

A: About 35 days after receipt of payment. |

|

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment. |

|

Q: What your main customers?

A: Huawei, Foxconn, Vtech, Sumida, Kemet, Vishay, Bosch, Canon, Jabil etc. |

|

Q: Why choose you?

A: Leading SMT Supplier in China; Professional Supplier on Alibaba; Trade assurance to USD 560,000+; Professional after-sales service team. |

Hot Searches