- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380

-

Dimension(L*W*H):

-

.

-

Weight:

-

1000 KG

-

Application:

-

Gold

-

Installation:

-

Engineer Guide

-

Recovery rate:

-

95-98%

-

Feeding Size:

-

0-2mm

-

Processing capacity:

-

1-20h/t

-

Main products:

-

jaw crusher, wet pan mill, concentrator, ball mill

Quick Details

-

Production Capacity:

-

98

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NESTOR

-

Voltage:

-

220/380

-

Dimension(L*W*H):

-

.

-

Weight:

-

1000 KG

-

Application:

-

Gold

-

Installation:

-

Engineer Guide

-

Recovery rate:

-

95-98%

-

Feeding Size:

-

0-2mm

-

Processing capacity:

-

1-20h/t

-

Main products:

-

jaw crusher, wet pan mill, concentrator, ball mill

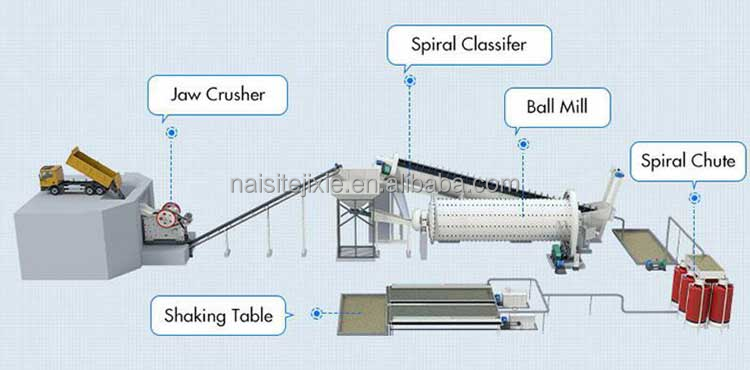

Products Information

WORKING PRINCIPLE OF SHAKING TABLE

The working principle of mini shaking table is to use the combined action of the specific gravity for different sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove), to allow loose layering of ores on the bed surface and fan-shaped zoning.

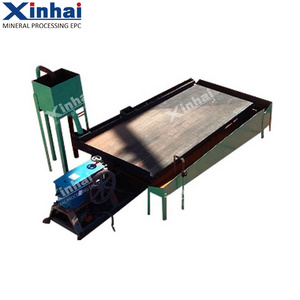

different types of shaking table for your different choice

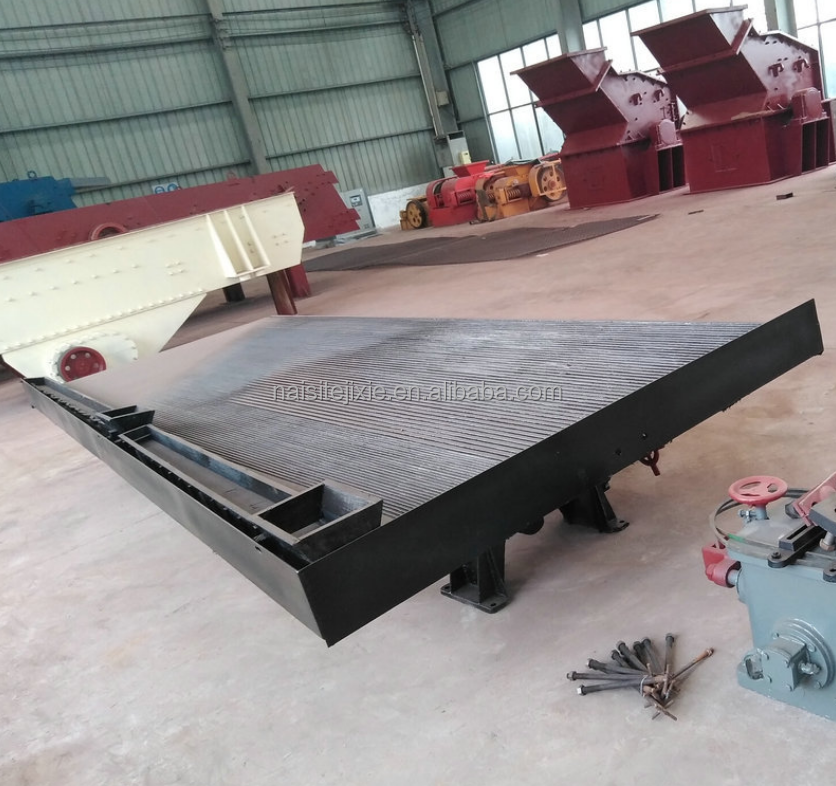

CONSTRUCTIONS OF SHAKING TABLE

This machine is composed of three parts, i.e. head of shaking table, surface of shaking table, as well as bearing and adjusting gradient.

1. Head of shaking table: This is eccentric connecting-rod type mechanism. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. When the connecting rod pushes down the toggle plate compression spring, the pull rod drives the table surface to move in the direction of table head. When the connecting rod pushes it upward, it, through the spring tension, drives the table surface to move in the opposite direction. When they are linked, the rotating motion of eccentric shaft is changed into horizontal alternating differential motion of table surface.

2. Shaking table for gold table surface: It is mainly composed of vibrating roof, steel skeleton, glass fiber reinforced plastics and wear-proof surface, feed water tank, feed chute, and draw bar. The table surface adopts steel skeleton FRP composite structure. That is, glass fiber reinforced plastics are pasted on steel skeleton to form a solid glass fiber reinforced plastic surface. Its above uses abrasion-proof materials to make surface and riffle (notch groove).

3. Bearing and Adjusting Gradient Mechanism: Shaker table for gold The bearing and adjusting gradient mechanism is mainly composed of shaking support plate, adjusting seat board, saddle seat, and adjusting screw rod. The shaking support plate enables the table surface to make arc forward and backward alternating movement on vertical plane. The shaking support plate and shaking box are fixed on the adjusting seat board with gripping channel steel. When hand wheel regulating screw rod is used to get the adjusting seat board to rotate on the saddle seat, the Transverse gradient of table surface can be adjusted.

1. Head of shaking table: This is eccentric connecting-rod type mechanism. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. When the connecting rod pushes down the toggle plate compression spring, the pull rod drives the table surface to move in the direction of table head. When the connecting rod pushes it upward, it, through the spring tension, drives the table surface to move in the opposite direction. When they are linked, the rotating motion of eccentric shaft is changed into horizontal alternating differential motion of table surface.

2. Shaking table for gold table surface: It is mainly composed of vibrating roof, steel skeleton, glass fiber reinforced plastics and wear-proof surface, feed water tank, feed chute, and draw bar. The table surface adopts steel skeleton FRP composite structure. That is, glass fiber reinforced plastics are pasted on steel skeleton to form a solid glass fiber reinforced plastic surface. Its above uses abrasion-proof materials to make surface and riffle (notch groove).

3. Bearing and Adjusting Gradient Mechanism: Shaker table for gold The bearing and adjusting gradient mechanism is mainly composed of shaking support plate, adjusting seat board, saddle seat, and adjusting screw rod. The shaking support plate enables the table surface to make arc forward and backward alternating movement on vertical plane. The shaking support plate and shaking box are fixed on the adjusting seat board with gripping channel steel. When hand wheel regulating screw rod is used to get the adjusting seat board to rotate on the saddle seat, the Transverse gradient of table surface can be adjusted.

Product Application OF SHAKING TABLE

mini shaking table is one of the main equipment for gravity classification, which is widely applied in the classification of

tungsten, tin, tantalum, columbium and other rare metal and precious metal ore. gold table is designed for wet gravoty-base separatiom of mineral and other granular materials. It is effective in processing precious and base metal, rare and non-metallic minerals.

tungsten, tin, tantalum, columbium and other rare metal and precious metal ore. gold table is designed for wet gravoty-base separatiom of mineral and other granular materials. It is effective in processing precious and base metal, rare and non-metallic minerals.

PRODUCT SPECIFICATIONS

|

Model Performance

|

LS4500

|

LY3000

|

LY2100

|

LY1100

|

|

Screen Size(mm)

|

4500×1850×156

|

3000×1620×11

|

2100×1050×85

|

1100×500×430

|

|

Stroke length mm

|

10-30

|

6-30

|

12-28

|

9-17

|

|

Frequency tpm

|

240-420

|

210-320

|

250-450

|

280-460

|

|

Horizontal slope °

|

0-5

|

0-10

|

0-8

|

0-10

|

|

Feeding Range mm

|

2-0.037

|

2-0.037

|

2-0.037

|

2-0.037

|

|

Feeding Density %

|

10-30

|

10-30

|

10-30

|

10-30

|

|

Capacity(t/h)

|

0.3-2.5

|

0.2-1.5

|

0.1-0.8

|

0.03-0.2

|

|

Water consumption

|

0.4-0.7

|

0.3-1.5

|

0.2-1

|

0.1-0.5

|

|

Motor power kw

|

1.1

|

1.1

|

1.1

|

0.55

|

|

Size(mm) l*w*h

|

5600×1850×860

|

4075×1320×78

|

3040×1050×10

|

1530×500×800

|

The Installing and Adjustment of Shaking Table

1. Carry out to detect bed ministries complying with the requirements of the drawings, parts

2. Lifting bed of the gold shaker table installed in front of the connector and four connected blocks

3. Hammock should prevent the local compression deformation of the side plates and shall collision bed

4. Bed installation, each connected to the screw holes should be aligned

5. Each bond inspection is correctly installed, the empty running 1-2 hours

6. Empty running is completed

2. Lifting bed of the gold shaker table installed in front of the connector and four connected blocks

3. Hammock should prevent the local compression deformation of the side plates and shall collision bed

4. Bed installation, each connected to the screw holes should be aligned

5. Each bond inspection is correctly installed, the empty running 1-2 hours

6. Empty running is completed

Successful Customer Case

Related Products

Hot Searches