- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Shunyue

-

Model Number:

-

SY554

-

Car Make:

-

General

-

Product name:

-

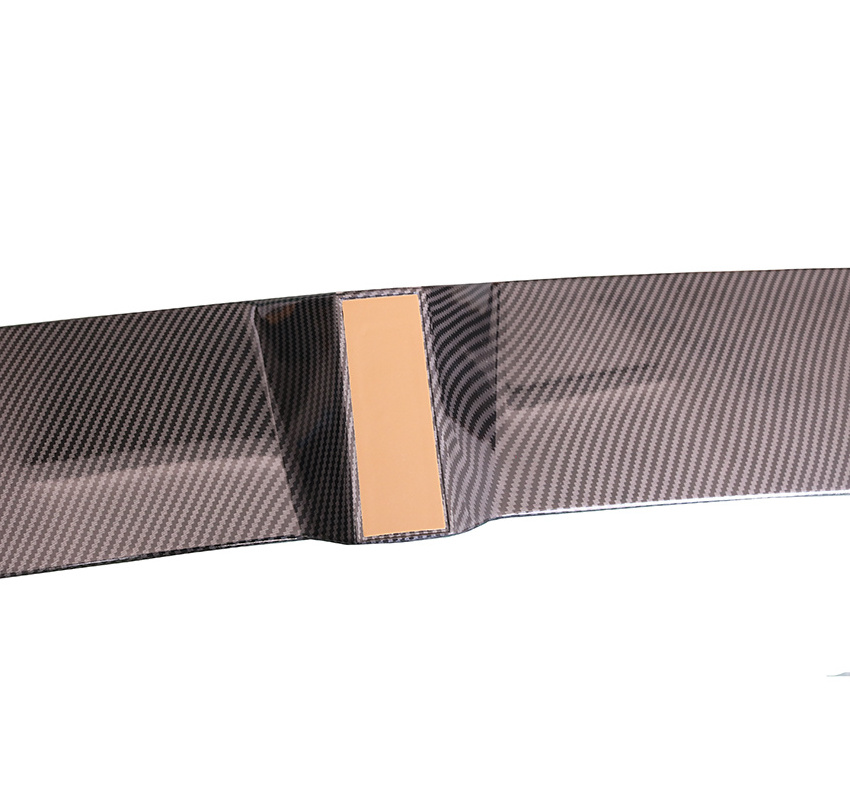

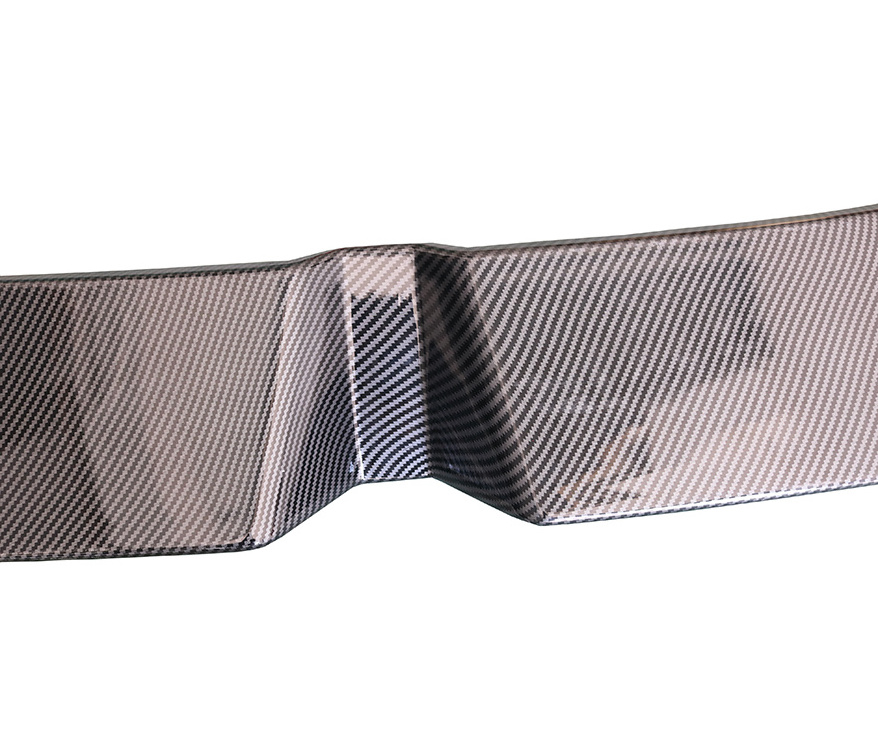

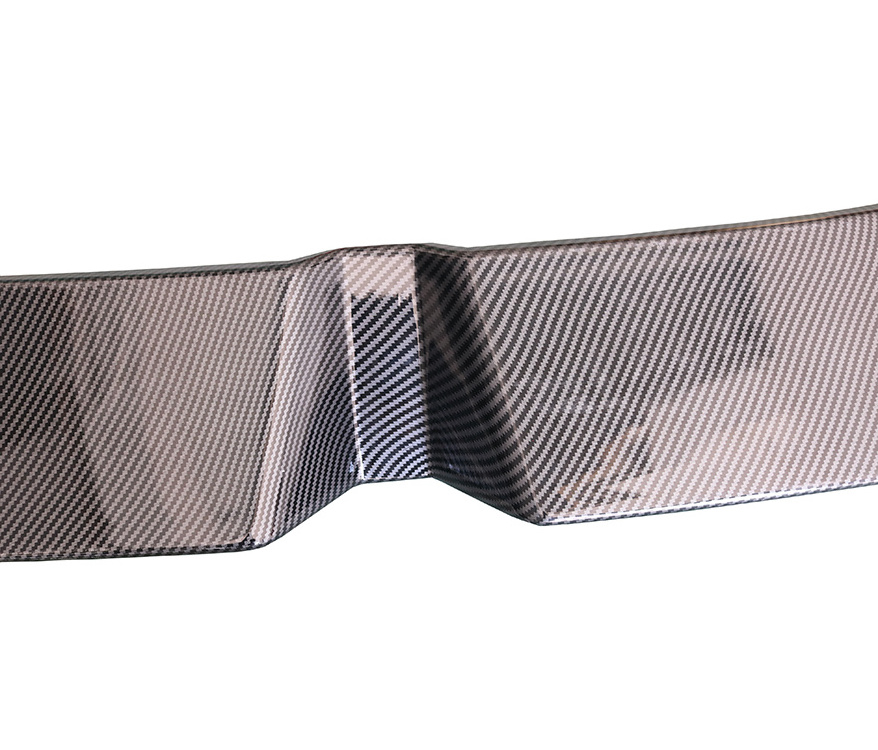

Carbon fiber Exterior Accessories Auto parts Car Tail Flap

-

Warranty:

-

1year

-

Car Model:

-

General

-

Design process:

-

Design drawing -moulding- forming

-

Service:

-

Provide car dete of model

-

Type:

-

OEM ODM Parts

-

Surface:

-

High polished

-

Protection:

-

PE film

-

Weight:

-

Light weight

-

Accessories:

-

Glue tape included

Quick Details

-

Deck:

-

Single

-

Material:

-

Carbon fiber

-

Size:

-

1240*155*90mm or customzied

-

Place of Origin:

-

China

-

Brand Name:

-

Shunyue

-

Model Number:

-

SY554

-

Car Make:

-

General

-

Product name:

-

Carbon fiber Exterior Accessories Auto parts Car Tail Flap

-

Warranty:

-

1year

-

Car Model:

-

General

-

Design process:

-

Design drawing -moulding- forming

-

Service:

-

Provide car dete of model

-

Type:

-

OEM ODM Parts

-

Surface:

-

High polished

-

Protection:

-

PE film

-

Weight:

-

Light weight

-

Accessories:

-

Glue tape included

1) P roduct description

1. P roduct name : Carbon fiber Exterior Accessories Auto parts Car Tail Flap

2. Products size : all kinds of parts completely customer customized

3. Material : Carbon fiber or depend on your requestments

4. Fabrication : Vacuum forming, CNC cut ting , scraping process silkscreen print ing , engraving, polishing etc

5. Application : Tail Flap for car parts

6. Customer customize . OEM/ ODM are welcome.

7. Large ABS vacuum forming plastic products . (size is 2.5*1.5*0.5m)

2)Material introduction

Carbon fiber

Feature:

1. High strength

2. Excellent heat resistance

3. Excellent thermal shock resistance

4. Small amount of change

5. Small specific gravity

6. Excellent anti-corrosion and radiation performance

7. Small heat capacity

Application:

Industrial and various industrial and civil buildings and structures are shockproof, crack-proof and anti-corrosive.

3 ) P r o ducts Making Procedure:

4) Why choose vacuum forming?

Thick sheet blister is to use 1.5-12mm thick plates or sheets to absorb the heated and softened plates or sheets to the surface of the mold through vacuum negative pressure, so that it basically conforms to the mold to shape . Then, through cutting machine,drilling, or five axis CNC machine, excess is removed to form the final desired product . This process has low mold cost, short production period, and short mold development time . Greatly r educed product cost and development cycle. According to customer requirements, we can produce products of various specifications and sizes to ensure the accuracy of your product assembly. Mainly used in industries such as automobiles, electronics, sports equipment, medical treatment, toys, equipment, display stands, handicrafts, mechanical hardware, etc. Compared with injection molding, thick sheet blister processing not only has low mold cost, but also has a short production cycle. In particular, it can solve the problem of high production costs caused by small production batches for users who are in the development and growth stages .

Packaging Details:packed with plastic,25sets/Ctn

(wrap it in a plastic bag, then add PE foam board, and finally put it in the carton)

or according to customer requirements, customized individual packaging

Port:Shenzhen,Guangzhou

Lead time:

|

Quantity(Sets) |

1 - 2 0 00 |

2 0 01 - 5 000 |

5 001 - 10 000 |

> 10 000 |

|

Est. Time(days) |

15 |

30 |

45 |

To be negotiated |

This is our production line, from raw materials to molded products, all completed in accordance with customer needs. There are a series of services such as drilling, engraving, cutting, polishing, and finally scraping the edge, packaging and transportation.