- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≤±1%

-

Driven Type:

-

Electric/pneumatic

-

Voltage:

-

24V/220V,50HZ,60HZ

-

Place of Origin:

-

ZHE

-

Brand Name:

-

QR Machinery

-

Dimension(L*W*H):

-

Related to model

-

Weight:

-

50 KG

-

Hopper capacity:

-

10-100L

-

Feature:

-

Work Efficiently

-

Material:

-

SUS304/SS316L Stainless Steel

-

Working speed:

-

10-60bottles/min(based on 250ml jam)

-

Air pressure:

-

0.4 ~ 0.9Mpa

-

Drive control form:

-

PLC precise pulse control of servo motor

-

Value-added services:

-

Online support, Video technical support

-

Marketing Type:

-

Hot Product 2024

-

Canning range:

-

10ml-300L

-

Canning accuracy:

-

≤1%

Quick Details

-

Machinery Capacity:

-

6000BPH

-

Packaging Material:

-

Paper, Wood

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice, Other, Flowing Liquid

-

Filling Accuracy:

-

≤±1%

-

Driven Type:

-

Electric/pneumatic

-

Voltage:

-

24V/220V,50HZ,60HZ

-

Place of Origin:

-

ZHE

-

Brand Name:

-

QR Machinery

-

Dimension(L*W*H):

-

Related to model

-

Weight:

-

50 KG

-

Hopper capacity:

-

10-100L

-

Feature:

-

Work Efficiently

-

Material:

-

SUS304/SS316L Stainless Steel

-

Working speed:

-

10-60bottles/min(based on 250ml jam)

-

Air pressure:

-

0.4 ~ 0.9Mpa

-

Drive control form:

-

PLC precise pulse control of servo motor

-

Value-added services:

-

Online support, Video technical support

-

Marketing Type:

-

Hot Product 2024

-

Canning range:

-

10ml-300L

-

Canning accuracy:

-

≤1%

|

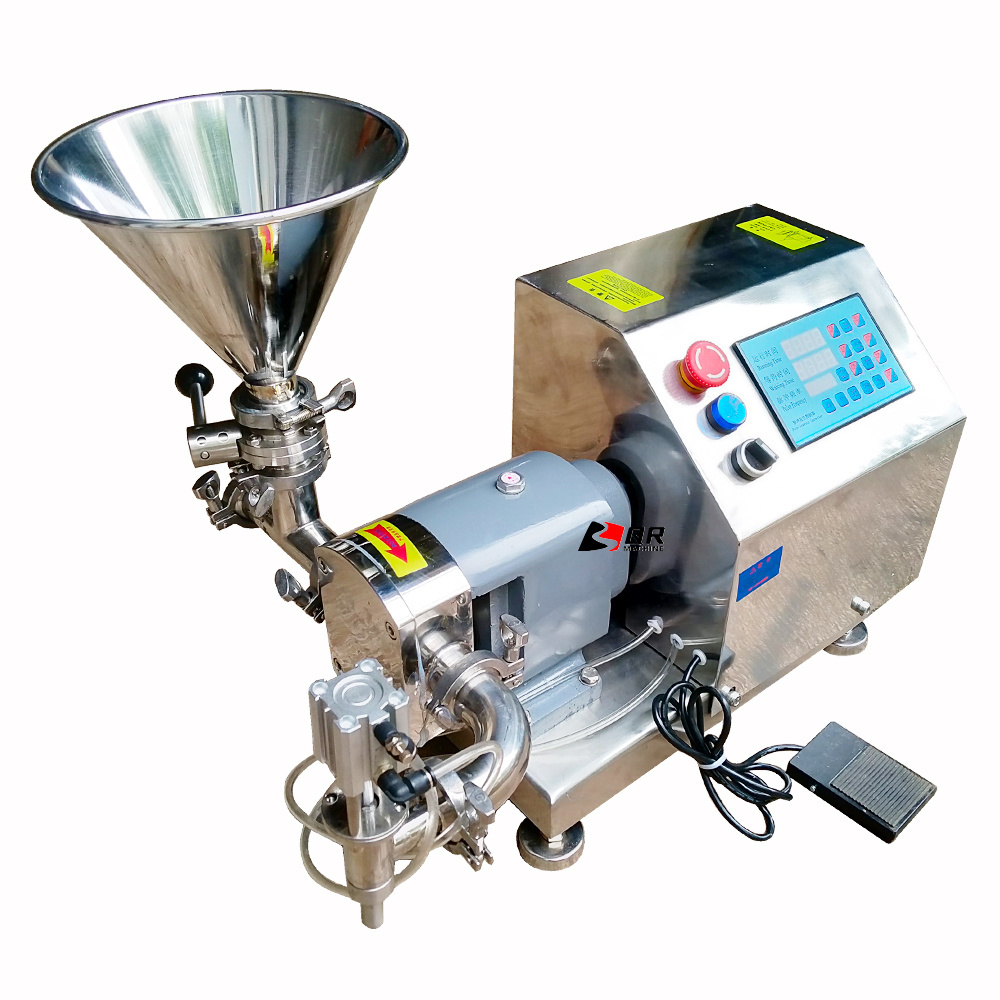

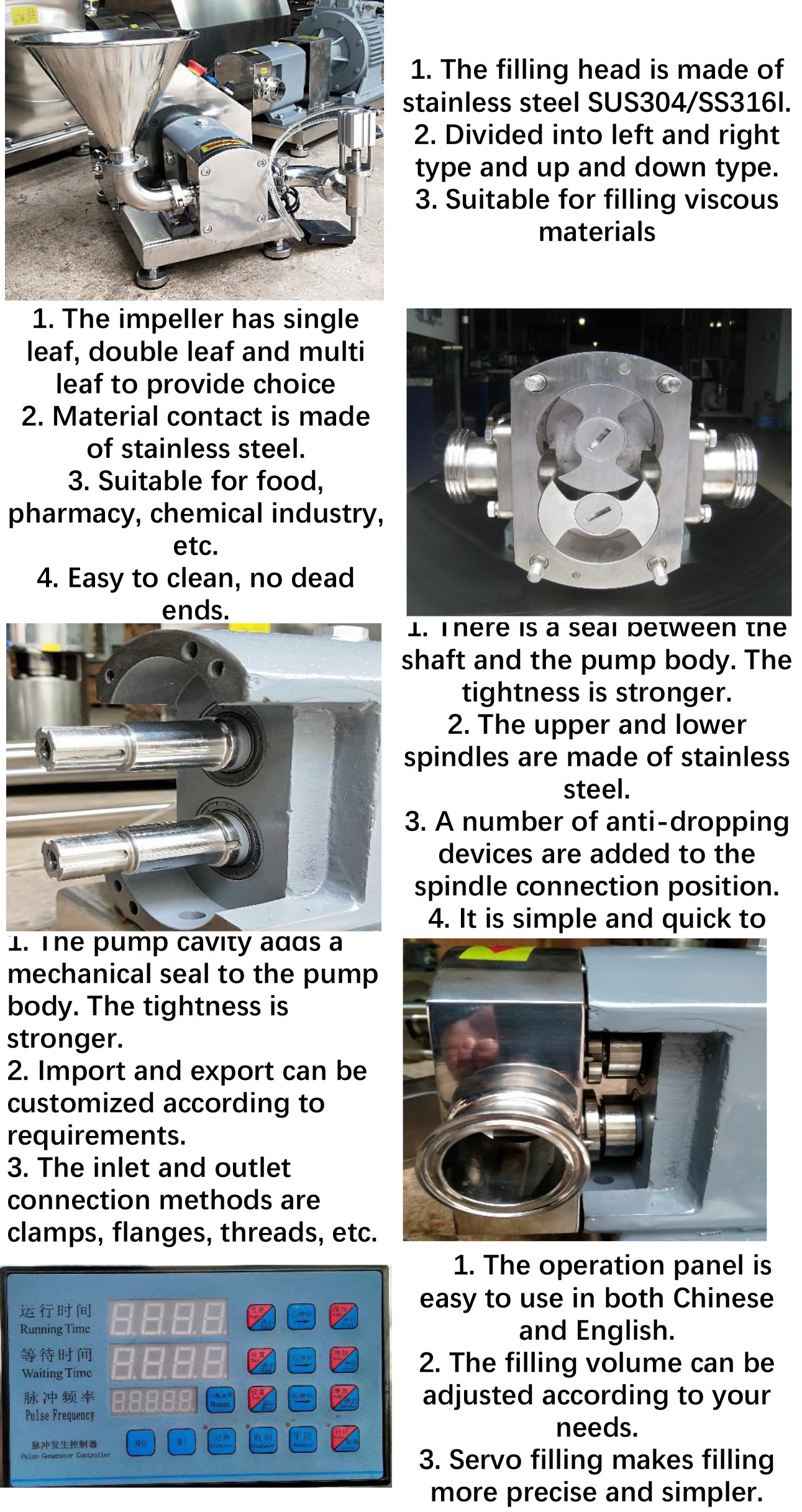

Shampoo

semi automatic filling machine

, this machine is suitable for

cosmetics, food industries etc.

It is an ideal equipment for filling

high-viscosity fluids

and pastes.This series of filling machines are divided into two types: left in and right out and top in and bottom out.

|

|

|

||

|

Factory Scale:

1) Located in: Zhejiang, China 2) Factory Area: 5000SQ.M 3) Employees: 37 4) Production Ability: 50 Pieces/Shampoo semi automatic filling machine |

Advantages:

1) Certificates: CE ,ISO9001 2) Warranty: 12 months 3) OEM/ODM: can design, exploitation and manufacture by CAD software and drawing. 4) Testing&QC: pressure test and material test |

|

||

|

Production Line

:

1) Engineers:

3

2) Workers: 20 3) Welding: 4 4) Polishing: 3 5) Testing: 2 6) Packing: 2 |

Delivery Time:

1) Material Preparation Time: 1 days 2) Metal Processing Time: 3-5 days, based on actrual quantity 3) Test & Packaging Time: 1 day |

|

||

Product details

Product introduction:

Semi-automatic filling machine

, different from the full

automatic filling machine

,

low cost, small size

. The main function of semi-automatic filling machine is filling, less with other functions, especially suitable for seasoning with granules and large

concentration of chili sauce, bean sauce, peanut butter, sesame sauce, jam,

and other substances of the thick sauce filling. The advantages of the equipment can be accurately measured by the two performance indexes of filling speed and measurement accuracy.

semi-automatic high efficiency filling machine

is undoubtedly the ideal equipment in the filling machine

Precautions for use:

1. Before using the filling machine, please fill the gear box with lubricating oil.

It is strictly forbidden to start the equipment without oil filling.

2. After the material is poured into the hopper, please press and hold the "dot" to make the material fill the pump cavity before use.

3. If the material does not flow or the oil-water separation is serious, please use a mixing hopper.

4. When filling high-viscosity materials, please adjust the "running speed" slowly, and increase the speed appropriately without jamming the machine.

5. The panel has a memory function. After setting the parameters, record the parameters until the next modification.

6. When flushing the filling machine, pour clean water or cleaning liquid into the hopper and adjust the "running speed" to use.

2. After the material is poured into the hopper, please press and hold the "dot" to make the material fill the pump cavity before use.

3. If the material does not flow or the oil-water separation is serious, please use a mixing hopper.

4. When filling high-viscosity materials, please adjust the "running speed" slowly, and increase the speed appropriately without jamming the machine.

5. The panel has a memory function. After setting the parameters, record the parameters until the next modification.

6. When flushing the filling machine, pour clean water or cleaning liquid into the hopper and adjust the "running speed" to use.

Scope of application:

Servo filling machine is used for

shampoo, detergent, toothpaste, glycerin, pigments, additives, adhesives

, chemical fibers:polyester fiber, man-made fiber, polypropylene fiber. Coating:

paint, ink, resin, chocolate, syrup, cream, mayonnaise, jam

Cosmetics:

creams and lotions, hair sprays, essential oils

.

Recommend Products

Applications

Why Choose Us

Quality engineering

Q&R Machinery Co., Ltd.

Q&R Machinery Ltd. is a professional manufacturer of processing machinery. Our main products include

high shear mixers

,

mixing tanks

,

Vacuum emulsification tank

,

CIP cleaning tanks

,

colloid mills

,

centrifugal pump

,

E

mulsification pump

,

milk cooling tanks

,

Jacketed kettle

,

concentrators

,

UHT sterilization

,

Efficient batching machine

,

filling machines

,

sanitary filters

, sanitary pipes and valves. We are widely used in

beer, dairy, beverage,

chemical

,

cosmetic

,

industries

. We provide a complete set of services from Q&R,

design, production, sales, after-sales

to maintenance." The "Q&R" trademark is our promise to our customers that we will go forward and do better. We are looking forward to explore the market with you!

Workshop corner

FAQ

1:Are you manufacturer?

Yes, we are. Welcome to visit our factory.

2:Can you change the machine voltage as our request?

Yes, we can.

3: How about the delivery time?

With the standard products delivery time will be15-35 days after we receive your payment.

4: What's the payment terms?

Usually is T/T, L/C, or Western Union. We also accept Money Gram, PayPal and other payment terms.

5: Where are the main markets for your products?

Products have been exported to all over the world, especially in Northern Europe Western Europe, Eastern Europe North American,South American, Middle East, South Asia, Eastern Asia, African and etc.

Yes, we are. Welcome to visit our factory.

2:Can you change the machine voltage as our request?

Yes, we can.

3: How about the delivery time?

With the standard products delivery time will be15-35 days after we receive your payment.

4: What's the payment terms?

Usually is T/T, L/C, or Western Union. We also accept Money Gram, PayPal and other payment terms.

5: Where are the main markets for your products?

Products have been exported to all over the world, especially in Northern Europe Western Europe, Eastern Europe North American,South American, Middle East, South Asia, Eastern Asia, African and etc.

Inquiry Now

Hot Searches