- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380-440

-

Dimension(L*W*H):

-

1500x12000x600

-

Weight:

-

2000 kg

-

Processing Type::

-

pulp maolding machine

-

Type of Material:

-

virgin pulp

-

Raw material:

-

Wood pulp; Or bagasse pulp; Or bamboo pulp; Or straw pulp

-

Chemical for Oil Resistance:

-

1.2~1.6kg/h

-

Molds::

-

Aluminium

-

Forming method:

-

full automatic Vacuum forming

-

Drying method:

-

full automatic thermoforming drying (drying in mould)

-

Control system:

-

PLC + touch screen control

-

Finished Products:

-

Paper food container/disposible tableware, paper plate,fast food box

-

Forming Type:

-

Dry And Cut In Mold

Quick Details

-

Production Capacity:

-

6-8 molds/min

-

Place of Origin:

-

shandong

-

Brand Name:

-

Demeng or OEM

-

Voltage:

-

380-440

-

Dimension(L*W*H):

-

1500x12000x600

-

Weight:

-

2000 kg

-

Processing Type::

-

pulp maolding machine

-

Type of Material:

-

virgin pulp

-

Raw material:

-

Wood pulp; Or bagasse pulp; Or bamboo pulp; Or straw pulp

-

Chemical for Oil Resistance:

-

1.2~1.6kg/h

-

Molds::

-

Aluminium

-

Forming method:

-

full automatic Vacuum forming

-

Drying method:

-

full automatic thermoforming drying (drying in mould)

-

Control system:

-

PLC + touch screen control

-

Finished Products:

-

Paper food container/disposible tableware, paper plate,fast food box

-

Forming Type:

-

Dry And Cut In Mold

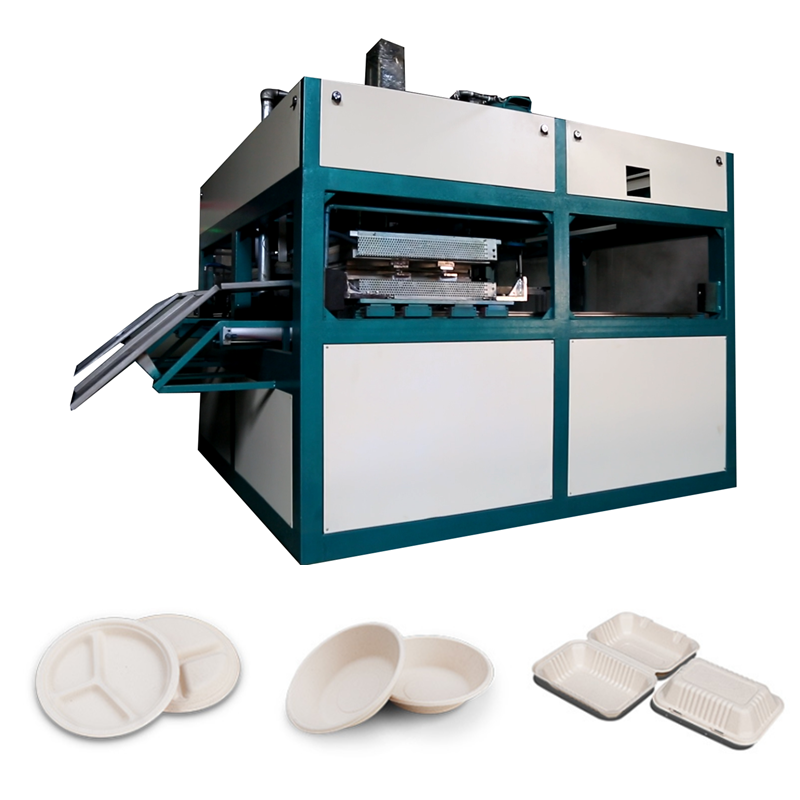

Plate Lunch Food Box Making Machine/Wheat Straw Sugarcane Bagasse To Pulp molding Tableware Paper Plate Machine

Product Type

:

Pulp Tableware Machine For Paper Lunch Box/Food Containers/Food Dishes/Paper Plate/Bows/Cups ect...

Processing Type

: Pulp Molding Machine

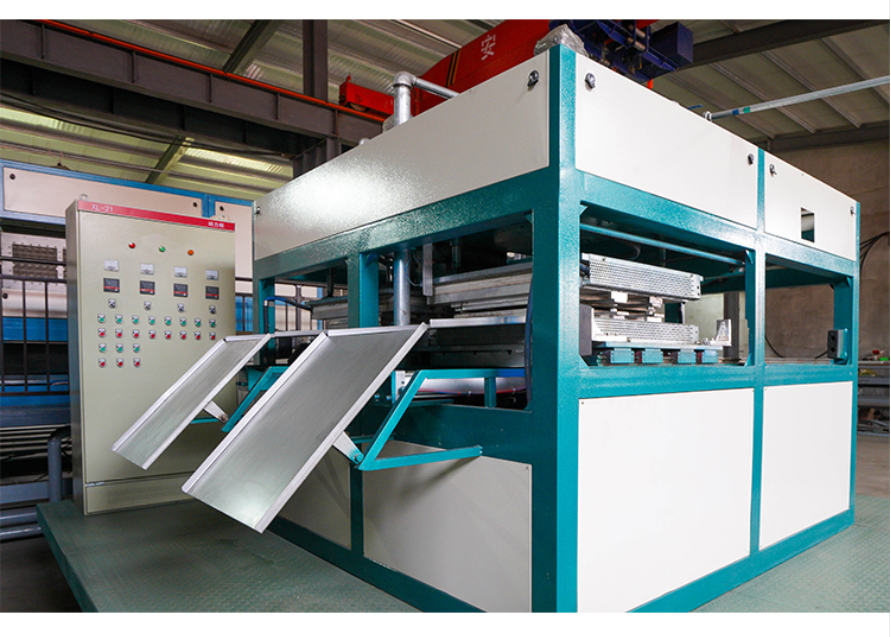

Platen size: 1350*1250 mm /1550*1250 mm

Independent air chamber and heating unit structure

Suitable for production of high quality egg carton, tableware, paper lunch box, medical care products, industrial pack, inserts and tray, etc.

Can produce high-precision free trimming products.

Can be equipped with high-efficiency heat insulation device, to achieve quick die change, high efficiency, energy saving

Disposable automatic tableware machine pulp plate making machine

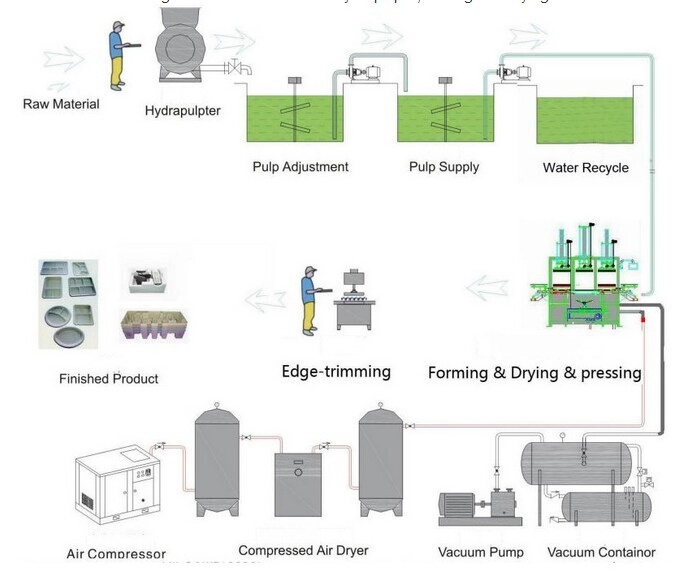

The automatic tableware machine is mainly applied for producing pulp molding one time use tableware, medical care items, high end industrial packaging products and so on.

|

Product Name |

pulp paper plate/tableware making machine |

|

Forming Machine |

vacuum suction and Reciprocating |

|

Heating Type |

heating in mold by Electric |

|

Raw Material |

Bagasse pulp, bamboo pulp, wood pulp, straw pulp |

|

Designed Capacity |

400 - 500 KG/Day, 700-1000KG/Day,ect |

|

Control By |

PLC + Touch screen |

|

Automation |

Fully Automatic |

|

Remarks |

* Pulp molding equipments are non-standard equipments , and we are able to provide customized solutions according to customers' specific requirements, such as customized design according to customers' production site requirements. |

Advantage for Sugarcane Bagasse Pulp Disposable Food paper lunch box machine

1. Raw material: virgin fiber, wood pulp, grass pulp, bamboo pulp or bagasse pulp or straw pulp

2. Automation: Fully-automatic control

3. Quality standard: CE

4. 100% environmentally production process.

5. Engineers available to service machinery overseas

1)Packing: export standard packaging

2)Port Departure: Qingdao Port

We use export standard packaging for all our products.

Q: . Why I choose your company?

A: a) We are the Leading foam machine Manufacturer in China.

b) We have made foam machine about 30 years with strong experience and advanced technics.

c) Best Quality & Best Service with Competitive price.

d) 100% inspection Before Shipment, and got CE certificate.

e) We have Professional technical team, supply 24 hours service.

f) One year guarantee and lifetime maintenance.

Q : What is the material of PE foam sheet production line ?

A : Polyethylene, Talcum powder, Butane, GMS ( glycerin monostearate ).

Q : What should we prepare except material?

A : You should prepare workshop, water line, electric line, compress air (if you need, we can help you buy air compressor).

We can supply workshop layout drawing according to your workshop.

Q: Where is your factory located? How can I visit there?

A: O ur factory is located in Longkou city, Shandong province, you can fly to Yantai or Qingdao airport, Yantai airport is nearer than Qingdao airport.

When you confirm flight No. and time, please feel free to contact us, then we will pick up you on time.