(1)The whole cartridge filling line meets the requirements of the new GMP, and the bottle cleaning effect meets the new pharmacopoeia standards and requirements;

(2)This filling line is a full servo motor system control model, and the parameters that need to be adjusted can be adjusted on the touch screen;

(3)The advanced electrical control system is adopted, the operating speed can be steplessly regulated, with complete interlocking function, and the operating parameter display screen is displayed centrally;

(4)The heat source of the tunnel hot air circulation oven is evenly distributed, and the heat source removal effect is good;(5)The sterilizing drying oven is not only suitable for the drying, disinfection and sterilization of ampoules, vials and cartridge bottles, but also for the drying, disinfection and sterilization of other pharmaceutical glass bottles;

(6)Automatic recording of temperature recording and curve chart automatic printing;

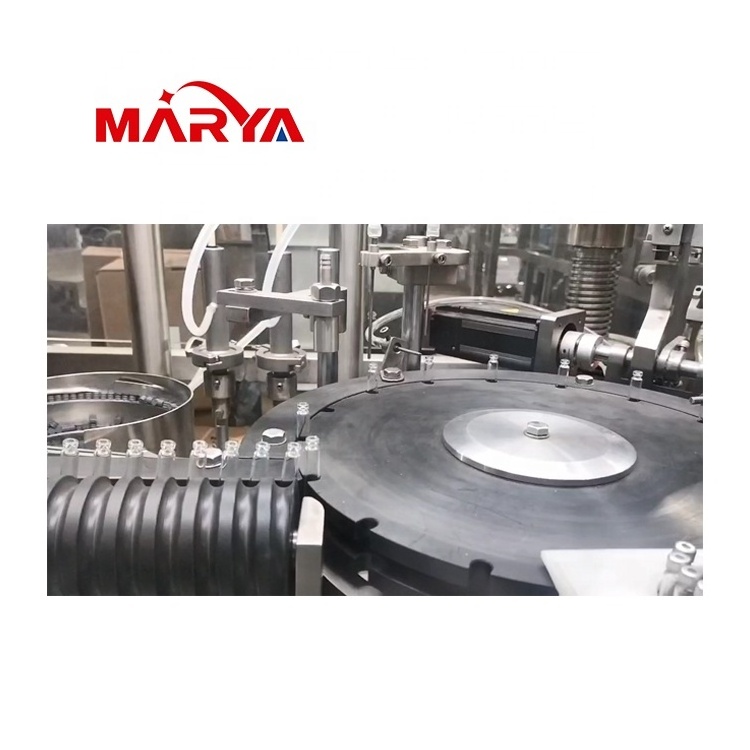

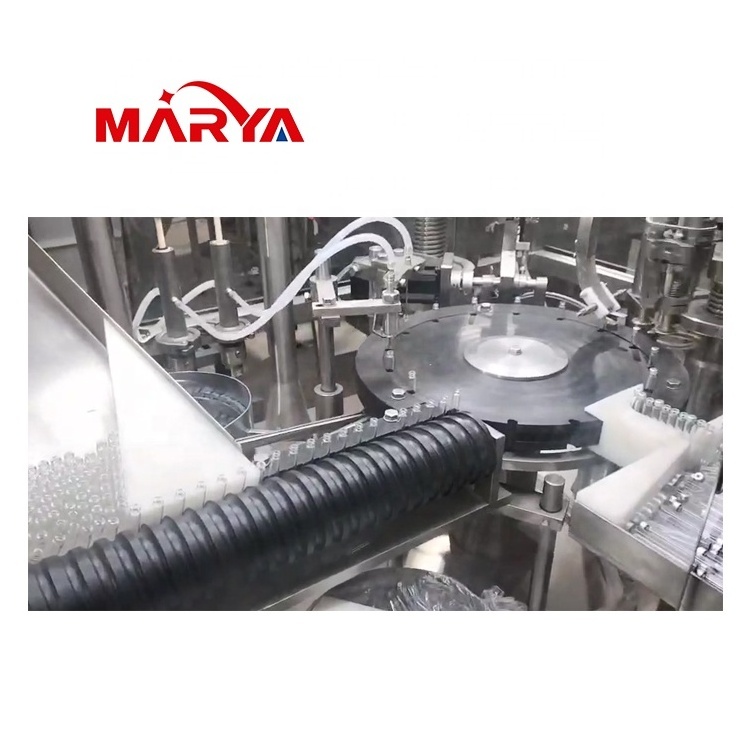

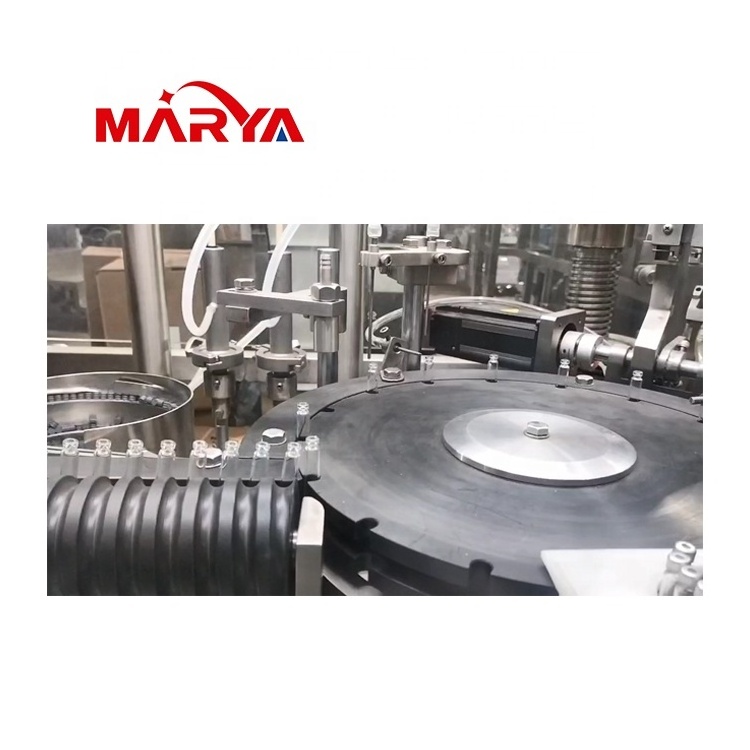

(7)Using positioning dial to walk bottles (servo motor driven) to walk 4 bottles at a time, filling positioning is accurate;(8)The ceramic rotary valve pump (8 sets) is used to fill in 2 times, the first filling is 50-70%, the second time is full filling, and there is a vacuum pumping needle at the mouth of the bottle filled in the second filling, and the excess little liquid is pumped into the recycling bottle through the pumping needle;

(9)The parts in contact with the chemical solution are 316L stainless steel or silicone, and the rest of the surfaces are 304 stainless steel or POM (PE);

(10)Marya cartridge bottle filling line has the function of full line linkage, and the front and rear equipment linkage control;(11)The use of high-precision color touch display operation monitoring, PLC automatic control, automatic protection, host frequency conversion speed regulation and other control technologies for the production process automatic control and monitoring;