- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tobee

-

Model Number:

-

4/3D-TH

-

Place of Origin:

-

China

-

Horsepower:

-

60 kw

-

Outlet Size:

-

3 inch

-

motor:

-

Electric

-

Email:

-

Sales3(at)tobepump.com

-

Model:

-

4/3D-TH

-

Material:

-

Ceramic

-

Brand:

-

Tobee

-

Motor:

-

Electric Motor

-

Size:

-

4''x3''

-

Capacity:

-

86.4-198 m3/h

-

Head:

-

9-52 m

-

Speed:

-

1000-2200 rpm

-

Website:

-

www.tobeepump.com

Quick Details

-

Application:

-

Food and Beverage Industry, Industrial Boilers, Industrial Utilities, Mining industry, SAG mill discharge, ball mill discharge, rod mill discharge, minerals concentrate, heavy media, bottom/fly ash, lime grinding, mineral sands, phosphoric acid, process chemical

-

Pressure:

-

Low Pressure

-

Voltage:

-

220v/380v/440v

-

Brand Name:

-

Tobee

-

Model Number:

-

4/3D-TH

-

Place of Origin:

-

China

-

Horsepower:

-

60 kw

-

Outlet Size:

-

3 inch

-

motor:

-

Electric

-

Email:

-

Sales3(at)tobepump.com

-

Model:

-

4/3D-TH

-

Material:

-

Ceramic

-

Brand:

-

Tobee

-

Motor:

-

Electric Motor

-

Size:

-

4''x3''

-

Capacity:

-

86.4-198 m3/h

-

Head:

-

9-52 m

-

Speed:

-

1000-2200 rpm

-

Website:

-

www.tobeepump.com

Product Description

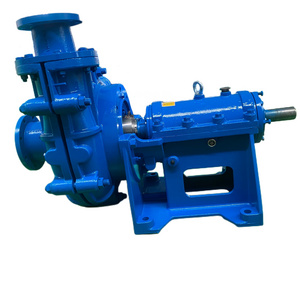

Slurry Pump

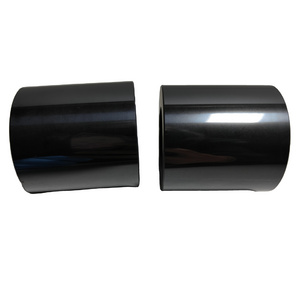

Shaft Sleeve

D075J04

Tobee®

D075J04 White Ceramic Shaft Sleeve can replace the standard Shaft Sleeve D075C21 for 4x3D-TH Slurry Pumps and 6x4D-TH Slurry Pump.

Slurry Pump Ceramic Shaft Sleeve, which has undergone destructive field tests for over 18 months, has proved to extend part life several times that of steel shaft sleeves on the same pump, same service. Total maintenance costs and down-time were reduced accordingly. Tobee's slurry pump ceramic shaft sleeves are precision formed of high density alumina, fired, and ground to size.

Tobee®

Interchangeable Slurry Pump Spares Parts:

Liners--Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

Casing--Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

Impeller--front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are complete interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

Throat bush--Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

Slurry Pump Shaft Sleeve Specifications

|

Part Name

|

Part Code

|

Material

|

Basic Code

|

Pump Model

|

|

Shaft Sleeve

|

D075J04

|

J04

|

075

|

4/3D-TH

|

Slurry Pump Main Parts

• Bearing assembly - A large diameter shaft with short overhang minimizes deflection and contributes to long bearing life. Only four through bolts are required to hold the cartridge type housing in the frame.

• Liners - Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

• Casing - Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

• Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are complete interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

• Throat bush - Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

• Liners - Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

• Casing - Casing halves of cast or ductile iron with external reinforcing ribs provide high operating pressure capabilities and an extra measure of safety.

• Impeller - front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are complete interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

• Throat bush - Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

Slurry Pump Spare Parts Shaft Sleeve Component Drawing

Slurry Pump Materials Application Areas

Tobee® Slurry Pump Parts widely used in Mining, Mineral Processing, Paper pulp, Sands, Gravels, Dredging, Coal Prep, Cyclone Feeds, Chemical Slurry Service, Tailings, Aggregate Processing, Ash Handling, Fine Primary Mill Grinding, Secondary Grinding, Iron Ore, Cooper, Oil field, Diamond, Alumina, Coal, Gold, Silver, Cement, Lead&zinc, Asbestos, Kaolin, Phosphorite, Bauxite, Potash, Mineral sands, Steel, Palm, Sugar, Steeloxyde, Chemical fertilizer, Molybdenum, Tin, Titanium, Power, FGD, Sea water, Food Processing, Cracking Operations, Pipeline Transport, High Velocity Hydraulic Transport,Food Processing, Explosive Sludge In Metal Smelting, River And Pond, Heavy Refuse Removal, Continuous (Snore) Sump Pump Operation, Abrasive Slurries, High Density Slurries, Large Particle Slurries, Sump Drainage, Wash down, Floor Drainage, Mixing, Frac Sand Blending, Tobacco, Construction, City Sewage, Industrial Processing etc.

Tobee Pump Company Advantages

Tobee® Pumps is More Convenient to Maintenance

Tobee® pump feature is that they are light in weight, small in size and simple in operation as compared to the imported pumps of the same flow, pump head and rotational speed.

Tobee® Pump Shaft Seals are Better Designed

Shaft seals are three kinds of Packing seal,Expeller seal and Mechanical seal, Tobee® Pump has been improved with better designs, greatly reduces the pressure

Tobee® Pump Operating Efficiency Is Higher

Since 1956, China began to inculcate the subject of major in Hydraulic Machinery in many Universities and Colleges in order to improve the theoretical research on the centrifugal pump efficiency

Tobee® Pumps are Better and More Advanced Hydraulic Design

In the Tobee® Pumps that we manufacture, the geometrical shape of the flow passage components conform to the optimal flow conditions of the medium and hence this reduces vortexes and impacts.

Tobee® Pumps are More Wear-resistance and Longer Work Life

We adopt the highest-grade materials in our pumps so as not to compensate on the quality of our pump products.

Tobee® Pumps are More Stable and Reliable Frame Bearings

We have taken great care to design the frame bearing parts of the Tobee® Pump in a reasonable manner, which is to say that the frame bearing components of our pumps are longer than those of the other pumps.

FAQ

Q: Are you a factory or trading company?

A:We are a big manufacturing pump factory with 35 years experience.

Q: Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China. You can fly to Shijiazhuang airport directly. All our

clients, from home or abroad, are warmly welcome to visit us!

Q: What is the material of your pumps?

A: The materials can be selected by High chrome alloy or Rubber, Polyurethane, Cast iron, SS304, SS316, CD4MCu, Duplex SS, Bronze etc. We can also choose material as customers' requirement.

Q: Can I get some technical support?

A: Yes, of course, we will continually provide full support by 7x24.

Q:How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end. Our

factory has 15~20QC.

A:We are a big manufacturing pump factory with 35 years experience.

Q: Where is your factory located? How can I visit there?

A:Our factory is located in Shijiazhuang City, Hebei Province, China. You can fly to Shijiazhuang airport directly. All our

clients, from home or abroad, are warmly welcome to visit us!

Q: What is the material of your pumps?

A: The materials can be selected by High chrome alloy or Rubber, Polyurethane, Cast iron, SS304, SS316, CD4MCu, Duplex SS, Bronze etc. We can also choose material as customers' requirement.

Q: Can I get some technical support?

A: Yes, of course, we will continually provide full support by 7x24.

Q:How does your factory do regarding quality control?

A: Quality is priority. We always attach great importance to quality controlling from the very beginning to the very end. Our

factory has 15~20QC.

Contact Us

Bella Zhang

HEBEI TOBEE PUMP CO., LIMITED

Email: Sales3@tobeepump.com | Mob: +86-18000656103 | Whatsapp: +86

18000656103

| Fax: +86 311-87221317

Web: www.tobeepump.com | Web: www.slurrypumpsupply.com | Web: www.tobee.cc | Web: www.hydroman.cn |

Web: www.tobee.store

Hot Searches