- Product Details

- {{item.text}}

Quick Details

-

Name:

-

double enamel water tank water tanks bitumen water storage tanks

-

Material:

-

Double enamel steel sheet

-

Color:

-

White,blue,green, or as customers' requirement

-

PH:

-

1-14

-

Service life:

-

more than 30 years

-

Holiday test:

-

>1500V

-

Coating thickness:

-

0.25-0.40mm

-

Adhesion:

-

3,450 N/cm

-

Hardness:

-

6.0Mohs

Quick Details

-

Core Components:

-

storage tanks

-

Place of Origin:

-

Hebei, China

-

Weight (KG):

-

100 kg

-

Name:

-

double enamel water tank water tanks bitumen water storage tanks

-

Material:

-

Double enamel steel sheet

-

Color:

-

White,blue,green, or as customers' requirement

-

PH:

-

1-14

-

Service life:

-

more than 30 years

-

Holiday test:

-

>1500V

-

Coating thickness:

-

0.25-0.40mm

-

Adhesion:

-

3,450 N/cm

-

Hardness:

-

6.0Mohs

double enamel water tank water tanks bitumen water storage tanks

Note: Dear Customer, different volumes of tanks have different prices, please consult our online sales for the quotation of every tank before you place an order. Thank you!

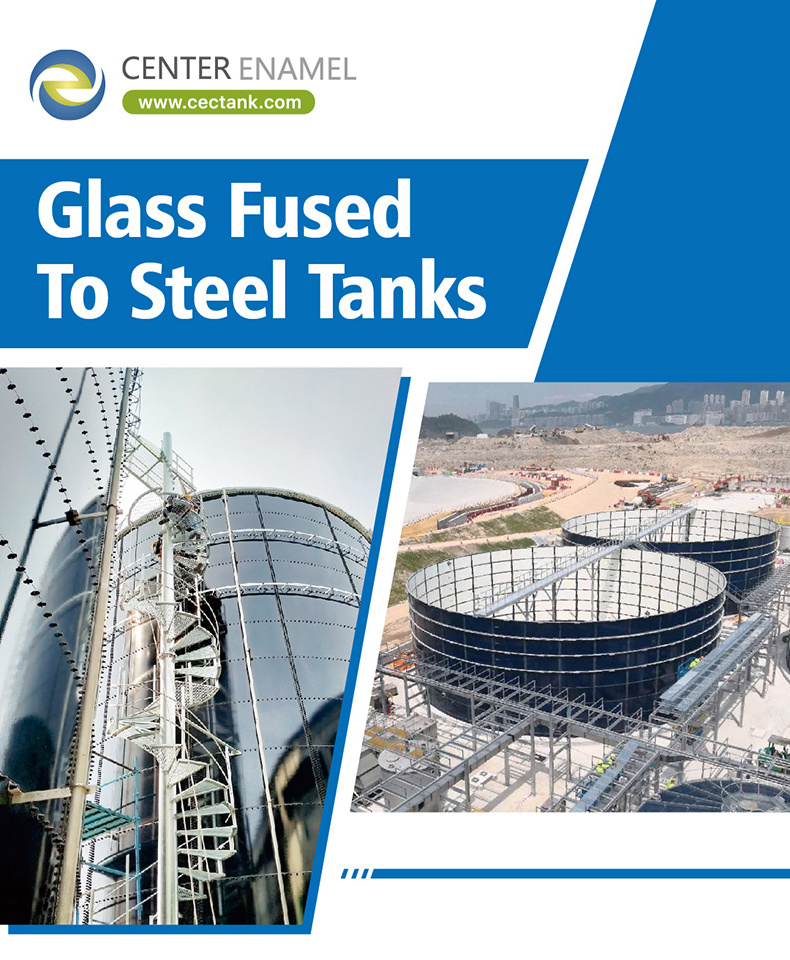

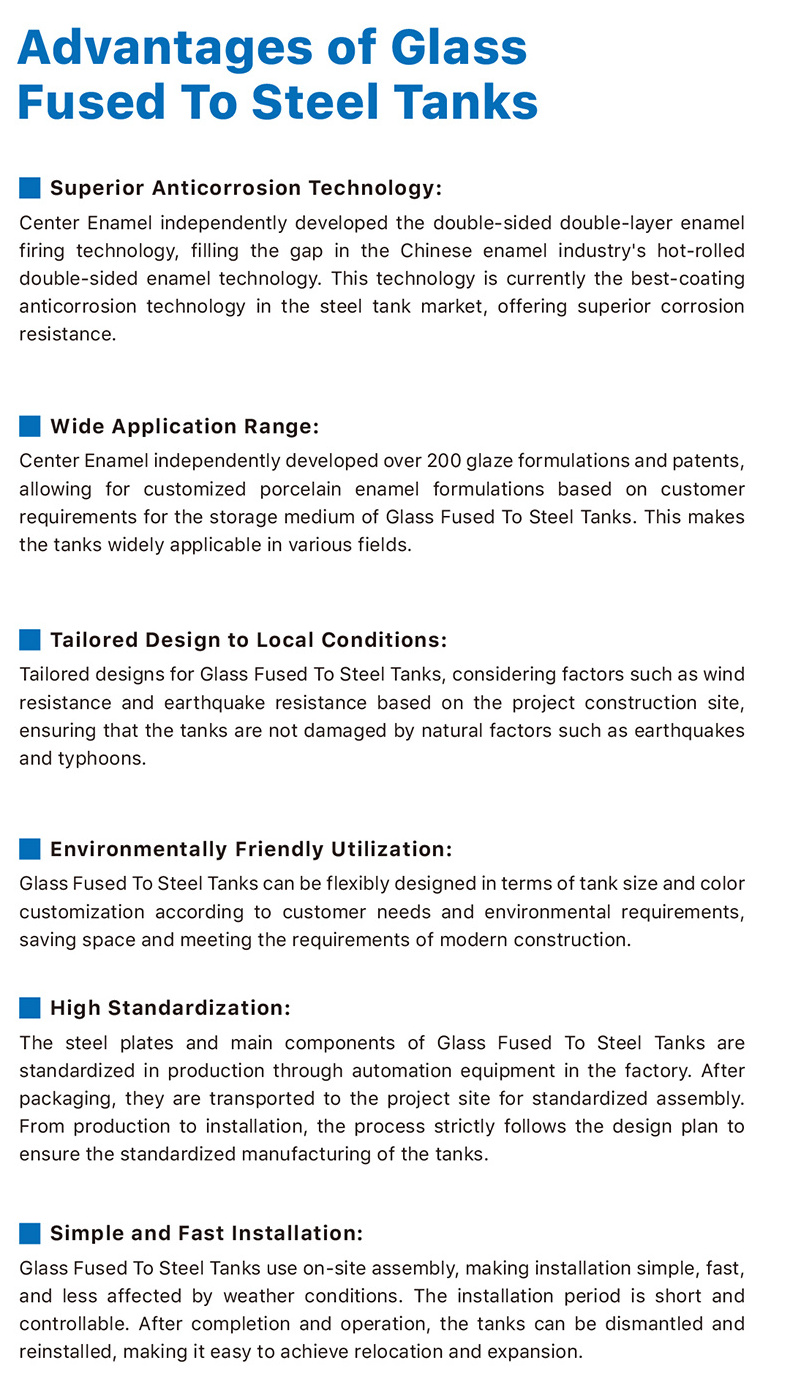

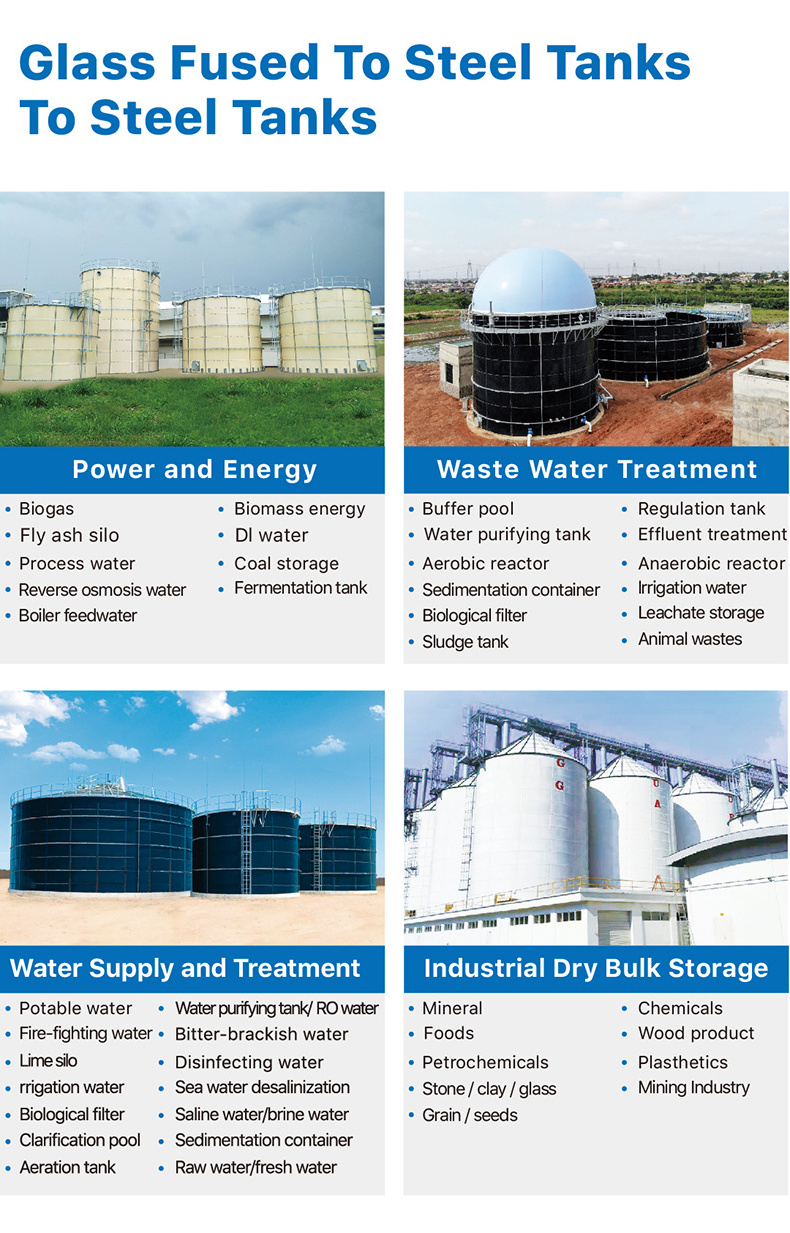

Glass-Fused-to-Steel tanks (GFS tanks), also known as glass-lined steel tanks (GLS tanks), are an advanced storage tank solution. They are produced by firing at a high temperature of 820°C-930°C, causing the molten glass to react with the surface of the steel plate. This process fully leverages the optimal performance of both materials, forming a robust and corrosion-resistant bond. The technique seamlessly combines the strength and flexibility of steel with the excellent corrosion resistance of glass, enabling Glass-Fused-to-Steel tanks to provide years of service in harsh environments. Compared to traditional fusion bonded epoxy tanks or welded steel tanks, GFS tanks have several advantages. We also offer various accessories to meet the needs of your facility, such as manholes, flanges, top cover handles, tank maintenance ladders, and platforms.

Glass-fused-to-steel technology is an advanced coating technology in the tank market. The molten glass coating endows the product with outstanding corrosion resistance and wear resistance, validated through decades of installations. The modular bolted connection design of GFS tanks makes them more economically efficient in on-site installation. and Shijiazhuang Zhengzhong Technology Co.,Ltd Glass Fused to Steel tanks (GFS tanks)conform to AWWA D103-09, OSHA, ISO 28765, NSF/ANSI 61, NFPA and other international standards , and are widely used in bio-energy, municipal sewage, landfill leachate and industrial wastewater treatment etc. applications

Glass Fused To Steel Tanks Specifications

|

Category |

Specification |

|

Coating Color |

Black blue, Grey olive, Forest green, Cobalt blue, Desert tan etc. |

|

Coating thickness |

0.25-0.45mm |

|

Acid and alkalinity proof |

Standard PH: 3~11, Special PH:1~14 |

|

Adhesion |

3450N/cm² |

|

Hardness |

6.0 (Mohs) |

|

Service life |

≥30 Years |

|

Holiday test |

>1500V |

|

Permeability |

Gas liquid impermeable |

|

Easy to clean |

Smooth, glossy, inert, anti-adhesion |

|

Corrosion resistance |

Excellent, suitable for harsh environment |

Shijiazhuang Zhongzhong Technology Co., Ltd (Center Enamel) . is a leading global storage tank manufacturer. The company adheres to independent research and continuous innovation, developing numerous advanced and environmentally friendly products guided by the market. It is not only the first manufacturer of Glass Fused To Steel Tank tanks in China but also the most experienced bolted tank manufacturer in Asia. The product range includes Glass Fused To Steel Tank tanks, fusion bonded epoxy tanks, stainless steel tanks, galvanized tanks, and aluminum dome roof s, providing global customers with services such as tank design and manufacturing, installation, commissioning, and technical support.

The engineering design, product testing, and quality system of Center Enamel 's products strictly adhere to international standards such as AWWA D103-09, OSHA, ISO 28765, NSF/ANSI 61, NFPA, and others. The tanks are widely used in drinking water, industrial wastewater, urban sewage, bioenergy, leachate from landfills, agriculture, and other applications.

To date, Center Enamel 's products have been exported to more than 90 countries, including the United States, Australia, Canada, Malaysia, Indonesia, Russia, the United Arab Emirates, Panama, Brazil, South Africa, etc. As an outstanding tank system supplier with over 30 years of experience, Shijiazhuang Zhongzhong Technology Co., Ltd. sincerely hopes to establish long-term cooperative relationships with local partners worldwide, contributing continuously to the development of the industry.