- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhongzhou

-

Model Number:

-

ZZXM-10

-

Dimension(L*W*H):

-

Defind

-

Warranty:

-

One Year

-

Certification:

-

CE BV

-

Name:

-

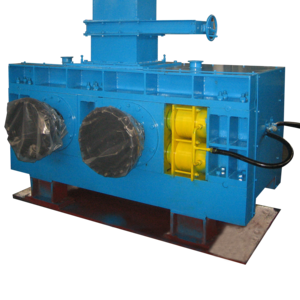

Metal powder ball press machine

-

Color:

-

Blue, green

-

Capacity:

-

10t/h

-

Raw material:

-

coal dust, charcoal dust, fine powder,iron powder

-

Roller width/ diameter:

-

According to product type

-

Total pressure:

-

According to product type

-

Roller materials:

-

65Mn, 9Cr2Mo, wear resistant alloy

-

Structural form:

-

Two rollers and single pressure/ Four rollers double pressure

-

Pressure:

-

machinery, hydraulic, spiral

-

Briquette shape:

-

round, pillow-shaped, oblate, oval-shaped, diamond

Quick Details

-

Production Capacity:

-

97%

-

Power:

-

18.5kw-30kw

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhongzhou

-

Model Number:

-

ZZXM-10

-

Dimension(L*W*H):

-

Defind

-

Warranty:

-

One Year

-

Certification:

-

CE BV

-

Name:

-

Metal powder ball press machine

-

Color:

-

Blue, green

-

Capacity:

-

10t/h

-

Raw material:

-

coal dust, charcoal dust, fine powder,iron powder

-

Roller width/ diameter:

-

According to product type

-

Total pressure:

-

According to product type

-

Roller materials:

-

65Mn, 9Cr2Mo, wear resistant alloy

-

Structural form:

-

Two rollers and single pressure/ Four rollers double pressure

-

Pressure:

-

machinery, hydraulic, spiral

-

Briquette shape:

-

round, pillow-shaped, oblate, oval-shaped, diamond

High quality high efficiency briquette piston press machine metal powder ball press machine

Introduction of metal powder ball press machine

This series of metal powder ball press machine can be used to make coal briquettes of different shapes. The raw material comes from small size waste charcoal broken in storage or while transportation, or comes from charcoal chunk after biomass burned. With this machine, the waste charcoal chunk can be made into charcoal briquettes or charcoal stick and recycled for barbecue, room heating etc.

Application of metal powder ball press machine

The purpose of metal powder ball press machine is to reduce dust, control volume-weight, improve transport characters and recycle materials. Briquette press machine has advanced technology and reliable quality. It is suitable for large, medium and small factory to build large scale production line. It is applied to industrial gas making, boiler, cold briquetting process, fired briquette, civilian use coal briquette, metallurgy, refractory materials, medicals and other fields.

It can press different powder into different shape. Such as, coal powder, charcoal powder, metallic powder (FeSi powder), iron scale, iron sludge, precipitator dust, iron concentrate, raw material powder, manganese ore fines, sli m e peat, fireproof material, desulfurized gypsum can be press into round and pillow shape.

Working principle of metal powder ball press machine

The metal powder ball press machine adds hydraulic oil into the hydraulic cylinder by the hydraulic pump, thus making the piston do axial displacement. The front connector of piston has been pressed against the bearing seat to meet the requirements for the production of pressure. When feed too much material in the two rollers of hydraulic briquetting press machine or there is some metal block there, the pressure that the hydraulic cylinder piston rod born will overload. Then the hydraulic pump will stop, the energy accumulator will play a buffer role on the pressure change, the relief valve will open for oil returning and the piston rod will shift to increase the the gap of the compression rollers to ensure hard objects to pass through the rollers. As a result, the system pressure will return to normal, which will protect the compression rollers from damaging. The hydraulic briquette press machine can adjust its pressure according to the requirements for the ball density, so production maneuvering is rather flexible.

Series hydraulic briquette press machine transfers its power through the reduction box to the two rollers simultaneously, making the two compression rollers rotate in opposite directions. During the rotation of the two rollers, the materials will enter into the ball mold on the compression roller. Along with rotating of the rollers, the pressure that the materials endured will grow from small to big, and it reaches peak when the materials rotate to the contact points of the line of the two rollers. Under the great linear pressure, the materials will turn into the finished ball from the powder in the end.

Final products of metal powder ball press machine

Company information

Zhengzhou Zhongzhou briquette machinery plant is the 23 years manufacturer in China which specialized to produce metal powder ball press machine, rotary dryer, various crusher and mixer etc equipment on briquettes production line. Our briquette machine own national patents,CE certification, since 1993 setting up factory ,Zhongzhou Brand briquette machine is more and more popular in China, the products account for 70% of the Chinese market, and have been exported to Ukraine, India, Korea, Malaysia, South Africa, Greece etc many aboard countries these years.

Customer satisfaction is what we are looking for. Also, we are engaged in external economic and technical cooperation. We respond to all customer inquiries, questions and requirements promptly. We really hope to become your supplier and partner in mechanical field.

Certifications

1.The mechanical manufacturer with 23 years history

2.Owning the design and manufacturing capability of super-large briquette machine

3.ZHONGZHOU is awarded the national registered trademark

4 .ISO9001:2000 international quality certificated enterprise

5.The French BV quality certificated obtained in 2013

6.The German CE quality certificated obtained in 2014

7.Independent enterprise with imp & exp permit for mechanical equipment

8.Having obtained the honorary title of the City Credit in 2006-2015

Patent1.Foue-roller double pressurization briquette machine Patent No:03284381.X

Patent2.Hydraulic and constant pressure briquette machine Patent No:03284382.8

Patent3.Roller assembly tamper attachment structure of briquette machine Patent No:200520030324.6

Patent4.Driving gear tamper assembly structure of briquette machine Patent No:200520030331.6

Patent5.Bearing structure of briquette machine Patent No:200520030393.4

Patent6.Metal mold for casting of roller ring of briquette machine Patent No:200520143701.7

Patent7.Drying oven of vertical dryer Patent No:ZL200720089834.X

Ways of packing for metal powder ball press machine

1.Payment Terms: L/C, T/T,D/P,D/A etc. the 50% by T/T in advance, the balance before delivery from factory

2.Delivery Time: Within 15 days after received your prepayment

3.Sand blasting, coat with high quality paint;

4.Product wrap by PP-Bubble

5.Load container, in iron case ,Spear Parts in wooden case.

6.Ocean freight partners are:

APL, COSCO, OOCL, CSCL, MSC, etc.

and train shipping is also available.

About Service System

1. Design reasonable proposal of briquetting line according to your detail requirements (material type, density, moisture content, size, capacity) at the most competitive price. We can suggest the wet briquetting process or dry briquetting process based on your materials’ performance and your special demand.

2. Professional advice for the binder method. Generally, the sodium silicate with liquid type and bentonite with powdery type are popularly used.

3. Specialized drawings are designed for you.

4. Arrange transportation to your destination port, cover insurance for you.

5. Inform detail shipping information for you in time.

6. When installation, give detail instruction,operation manual.

a) Installation and guidance

When the machine arrives at your company, we will dispatch our technicians to your company to guide the installation and commissioning at site. User should pay for the following fees air tickets, boarding and lodging and traffic in client’s factory. Allowance is about 70USD per day

b)Technical training

We provide free technical training service to your stuff. Training content contains the main work principle of machine, operating regulations, maintenance methods and steps, safety, etc.

c) Warranty:

Three guarantees of our product quality, warranty for one year (not include man-made damaged). We will maintain the machine for free for the quality problem. If the damage is caused by your improperly operation, the cost of the maintenance burden by you. we also provide you the life-long follow-up service .

Our customers

If you have any other questions about our machines, please send the inquiry. We are glad to cooperate with you!