- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

fiber mosquito coils paper mosquito repellent coil making machine

-

Raw material:

-

charcoal powder, waste paper and starch powder etc.

-

Application:

-

Making paper mosquito coils

-

Usage of mosquito repellent incense:

-

kill mosquito

-

Mosquito coil specification:

-

diameter 130-145m thickness 2-2.2mm

-

Mosquito coil burning time:

-

about 8 hours

-

Production efficiency:

-

100,000 pcs/day

-

Voltage:

-

380V 50HZ or custom made

-

Main equipment:

-

mosquito paper making part, mosquito coil forming part

-

Other type mosquito machine:

-

also have machine of black mosquito coils

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DAHENG

-

Model Number:

-

DH-ZWX

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

fiber mosquito coils paper mosquito repellent coil making machine

-

Raw material:

-

charcoal powder, waste paper and starch powder etc.

-

Application:

-

Making paper mosquito coils

-

Usage of mosquito repellent incense:

-

kill mosquito

-

Mosquito coil specification:

-

diameter 130-145m thickness 2-2.2mm

-

Mosquito coil burning time:

-

about 8 hours

-

Production efficiency:

-

100,000 pcs/day

-

Voltage:

-

380V 50HZ or custom made

-

Main equipment:

-

mosquito paper making part, mosquito coil forming part

-

Other type mosquito machine:

-

also have machine of black mosquito coils

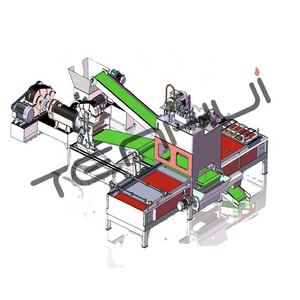

Paper mosquito coil production line:

Raw materials:

charcoal powder, waste paper ( waste news paper is best )

Finished product:

paper mosquito coils

Working process:

paper shaping machine ---- dewater ---- cut paper ---- paper mosquito coil forming machine ---- drying machine ---- collecting machine ---- placing and medical spraying machine ---- packaging machine

1. Mosquito paper board production line

Introduction:

This equipment is to produce new type mosquito coil paper sheet, final product is flat paper board.

Main parameter:

Main raw materials: waster writing paper, newspaper etc waste paper

Final product: mosquito coil paper sheet

Specification of paper: 1400-2000 g/m2

Width of paper: 1600-1700mm

Design speed: 80m/min

Working speed: 50m/min

Driven type: frequency conversion transmission

Size of fourdrinier wire: 11500mm*1950mm

Reeling drum: 1500mm*2000mm

Process flow of mosquito coil paper board:

waste paper and charcoal dust→ high concentration aquapulper→ pulp pump→ high concentration slag

separator→ high frequency vibrating screen→ pulp pool→ pulp pump→ efficient double disc pulp grinder

→ pulp pump→ agitator tank→ paper machine→ receiving paper platform→ suction crane platform→

finished product mosquito paper sheet

2. De-water machine

de-water the mosquito paper board, after pressing, the moisture is about 30%

3. Cut paper

cut mosquito paper into smalle paper sheet, then used for the mosquito coil forming machine

4. Paper mosquito coil forming machine

automatic paper mosquito coil forming machine

5. Drying machine for mosquito coils

dry mosquito repellent coils

heating fuel: coal or gas

drying temperature: 60-70 degree

6. Collecting machine for paper mosquito coils

collecting machine and transport table, includes belt conveyor, PLC controcl, frequency control

Model: DHSX-3.5

Power: 3.5kw

Voltage: 380V 50HZ

Production efficiency: 6-8 car/h

Oversize: 3850*3100*1600mm

Operator: 3 person

7. Placing machine for mosquito coils

double belt conveyor for placing the mosquito repellent coil, matched with mosquito spraying machine,

easy operation, low cost and highly increase the production efficiency

Model: DHFP-1.3

Power: 1.35kw

Voltage: 380V 50HZ

Production efficiency: 18000 pcs/h

Oversize: 2150*1600*600mm

Operator: 1 person

8. Medical spraying machine for mosquito coils

made of 304# stainless steel, double spraying, high efficiency, easy operation

Model: DHPY-300

Power: 1.2kw

Voltage: 380V 50HZ

Production efficiency: 300 pcs/min

Oversize: 2400*550*1250mm

9. Packaging mosquito coils machine

automatic packaging machine for packing mosquito repellent coils into plastic bags

Moulds and Mosquito Repellent Coils:

different moulds and mosquito repellent coils

we have production machine for black mosquito and paper mosquito

Pre-sale service:

1. Suggest to client suitable models of as customer need;

2. Introduce machine's structure and features in detail, explain the price component;

3. answer client concerned questions.

After-sale service:

1. Start production as soon as receiving down payment.

2. Send photos of machine in manufacturing and finished photos to client, for your better learn about the

machine's

condition.

3. Delivery machine in time, taking photos during loading, so you can "remote monitoring" your goods.

4. Documents and certificate available in time.

5. Manual documents available. Engineer can be sent to client site for installation instruction.