- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

VHANDY

-

Feature:

-

High Temperature Resistance

-

Color:

-

Ivory yellow

-

Shape:

-

According to design drawing

-

Density:

-

≥3.9g/cm3

-

Shipping:

-

By sea/By air/By express

-

Property:

-

Wear resistant/Acid resistant/Hrdness/Thermal shock resistance

-

Working temperature:

-

1450℃

-

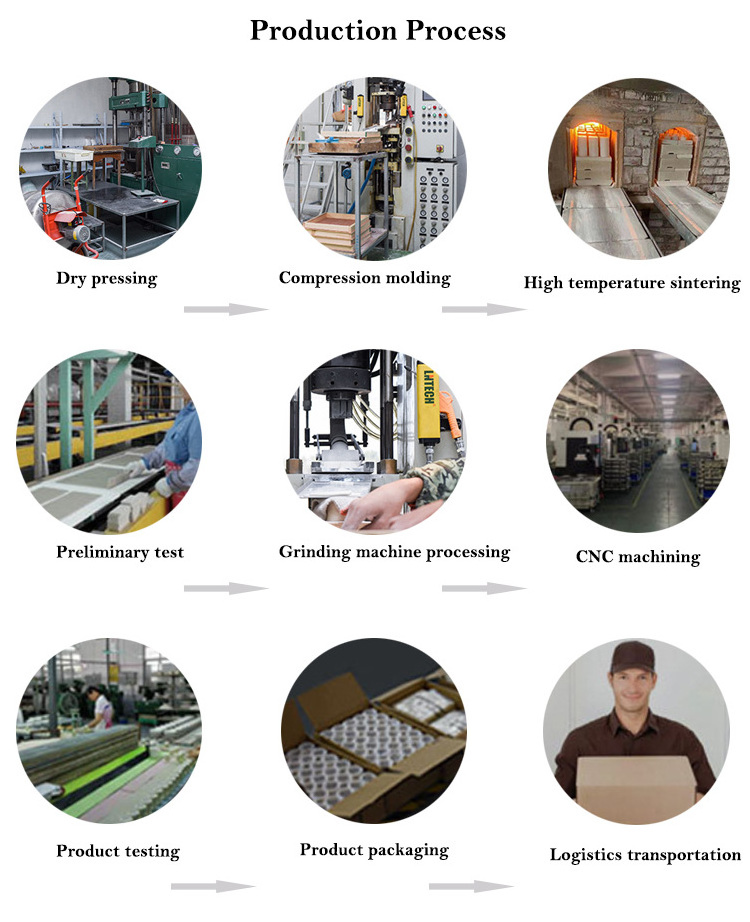

Producing method:

-

Tape casting

-

Tolerance:

-

According to design drawing

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Liaoning, China

-

Model Number:

-

custom made

-

Brand Name:

-

VHANDY

-

Feature:

-

High Temperature Resistance

-

Color:

-

Ivory yellow

-

Shape:

-

According to design drawing

-

Density:

-

≥3.9g/cm3

-

Shipping:

-

By sea/By air/By express

-

Property:

-

Wear resistant/Acid resistant/Hrdness/Thermal shock resistance

-

Working temperature:

-

1450℃

-

Producing method:

-

Tape casting

-

Tolerance:

-

According to design drawing

Product Description

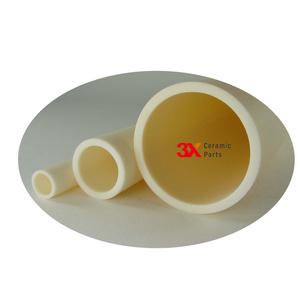

VHANDY 99% Alumina Ceramic Parts

1.VHANDY is professional with high quality 95%, 99%, 99.7% alumina ceramic parts;

2.Molding process is mainly hot, dry pressure, isostatic pressing;

3.Products alumina purity to meet customer requirements, tolerances can be controlled within ± 0.001mm range;

4.Surface roughness can reach Ra0.2um, for deep processing, the surface roughness can be controlled below Ra0.02um;

5.According to the use of ceramic pieces of the environment, recommend the best solution for customers.

2.Molding process is mainly hot, dry pressure, isostatic pressing;

3.Products alumina purity to meet customer requirements, tolerances can be controlled within ± 0.001mm range;

4.Surface roughness can reach Ra0.2um, for deep processing, the surface roughness can be controlled below Ra0.02um;

5.According to the use of ceramic pieces of the environment, recommend the best solution for customers.

Ceramic product function

1.A variety of specifications available.

2.Satisfy various technical request.

3.Lower medium spoilage.

4.Good insulation performance.

5.High strength.

6.Wear resistant performance.

7.High density.

8.refractory and high temperature resistance.

|

Item

|

Unit

|

95% Al2O3

|

99% Al2O3

|

99.7% Al2O3

|

ZTA

|

|

% Al2O3

|

%

|

95

|

99

|

99.7

|

70

|

|

Density

|

g/cm³

|

3.6

|

3.89

|

3.9

|

4.3

|

|

Porosity

|

%

|

0

|

0

|

0

|

0

|

|

Firing Temp

|

°C

|

1680

|

1700

|

1800

|

1600

|

|

Hardness

|

HV

|

1500

|

1600

|

1700

|

2000

|

|

Flexural Strength

|

Kgf/cm²

|

3000

|

3500

|

3500

|

4500

|

|

Compressive Strength

|

Kgf/cm²

|

25000

|

30000

|

30000

|

45000

|

|

Fracture Toughness

|

MPa/m

|

3~4

|

3.8

|

4

|

5~6

|

|

Max Operating Temp

|

°C

|

1450

|

1600

|

1700

|

1500

|

|

Coefficient

|

cm/cm/°C

|

8

|

5.6

|

8

|

8

|

|

Thermal Expansion

|

(RT to 700°C)

|

|

|

|

|

|

Volume Resistivity

|

20°C

(ohm - cm) |

10¹²

|

10¹²

|

10¹²

|

10¹²

|

|

|

100°C

(ohm - cm) |

10¹² -10

13

|

10¹² -10

13

|

10¹² -10

13

|

10¹² -10

13

|

|

|

300°C

(ohm - cm) |

10

10

|

10¹²

|

10¹²

|

10

10

|

|

Dielectric Strength

|

Volts/mil

|

210

|

216

|

220

|

210

|

Shooting in kind

Hot Searches