- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JC

-

Model Number:

-

JCMT06A

-

Type:

-

Liquid

-

Application:

-

metallic floor

-

Color:

-

transparent

-

Mixing Ratio:

-

A:B=2:1/3:1

-

Certificate:

-

REACH,RoHS,ISO9001

-

Rigidity:

-

84D

-

Hardening conditions:

-

25 ℃*4H to 6H or 60℃*1.5H (2 g)

-

Feature:

-

Good flowing property, low viscosity, bright in surface

-

Advantage:

-

Durable and Scratch Resistant

-

Performance:

-

Non Yellowing

-

Product Type:

-

2 part

Quick Details

-

CAS No.:

-

38891-59-7

-

Other Names:

-

epoxy resin floor

-

MF:

-

C15H16O2C2H7ONC3H5OCl

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JC

-

Model Number:

-

JCMT06A

-

Type:

-

Liquid

-

Application:

-

metallic floor

-

Color:

-

transparent

-

Mixing Ratio:

-

A:B=2:1/3:1

-

Certificate:

-

REACH,RoHS,ISO9001

-

Rigidity:

-

84D

-

Hardening conditions:

-

25 ℃*4H to 6H or 60℃*1.5H (2 g)

-

Feature:

-

Good flowing property, low viscosity, bright in surface

-

Advantage:

-

Durable and Scratch Resistant

-

Performance:

-

Non Yellowing

-

Product Type:

-

2 part

Leggari

Metallic

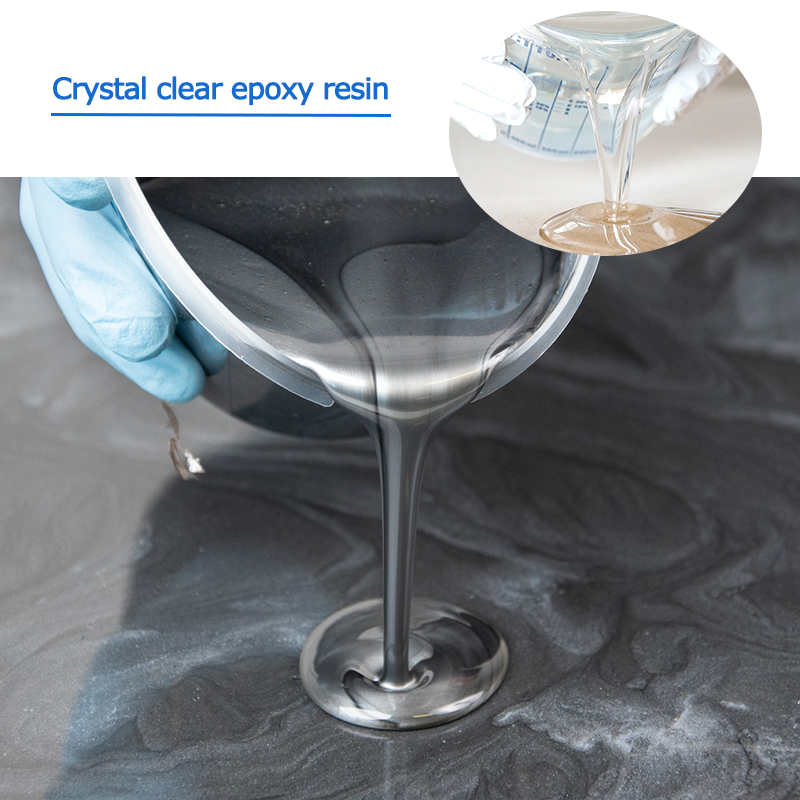

Clear Epoxy Resin Color Pigment Liquid Epoxy Resin for Epoxy Metallic Floor/Powder Coating

Jincheng Epoxy Floor Resin

system are the high-rated quality flooring products in the market ,it is most durable and easy to instal for any projects The metallic Epoxy floors are a seamless high-end and stunning look,which could be designed to cover existing interior concrete floors. It could be widely used for home ,garage,office ,showroom , shop, designer floor , industry or in fact just about anywhere.Can be used on all surfaces such as concrete, screed, wood and more.

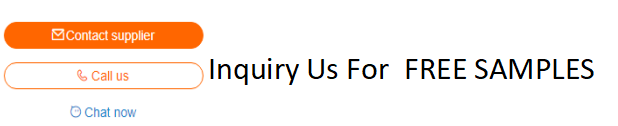

Product feature :

High hardness 85~90D

100% Solids BPA free

Crystal Clear, High Gloss

Solvent free,odorless

No Toxic

Organic Compounds,

NO VOC

Self-Leveling

Extremely

Durable,anti-scratich ,Anti slip

UV resistant

(with anti yellow formula),

Bubble Free

(with self bubble formula)

Tough Water Resistant &

Waterproof

Eliminates Craters, Crawling and Fish Eyes

Including primer ,middle coating and top coating products systems

Will not blush or sweat under high humidity

Will not distort with age

Very easy to apply

Good chemical resistance

made with high quality raw materials

Not considered flamble:FLAMMABILITY Class I

Specification

|

Part

|

JCMT06A

|

JCMT06B

|

||

|

JCMT06AColor

|

Transparent

|

Transparent

|

||

|

Specific gravity

|

1.15

|

0.96

|

||

|

Viscosity (25℃)

|

350-800CPS

|

150 -350CPS

|

||

|

Mixing ratio

|

A: B = 2:1/3:1

|

|

||

|

Hardening conditions 25 ℃

|

Light Foot traffic :24~48hours 72 hours for vehicular use and other heavy traffic.

|

|

||

|

Usable time

|

25℃×40min (100g)

|

|

||

|

Usage

|

Primer

(optoinal) : 0.1kgs per square meters thickness 0.1mm

Middle

coating:thickness 1mm, require 1kgs per SQ.M .

Coloring

: 4~6% around (more or less will be as per color effect).

2 options of

top

:1) 0.3kgs epoxy per SQ.M; 2) 0.06kgs water based PU resin per

SQ.M |

|

||

|

Application

|

Garage floor coating ,Industry floor coating ,Residential Floor coating ,Commercial floor coating and designer floors: showroom,shop,hotel ,or designer living space

|

|

||

|

Free Samples

|

Available 200 grams to test quality

|

|

||

|

Contact Us, We Will Provide You :

1. Good price with stable quality: WIN-WIN cooperation to support your business;

2. OEM with your target packing size and labeling your brands;

3.Fast delivery 3~5 days ,and logistic service support ;

|

|

|

||

OEM Packing

Steps epoxy flooring :

Step 2: Room Preparation and Calculations

Usage:

Epoxy Primer (optoinal)

: 0.1kgs per square meters for thin coating thickness 0.1mm (if floor not so flat and smooth ,should require more primer resin).

Epoxy Middle coating

: suggest coating thickness 1mm ~2mm, if coating 1mm, the usage of epoxy resin will be 1kgs per SQ.M .

Coloring

:Metallic pigment powder or solid pigment cream can be used to mix with middle coating resin

for coloring for making designer floor , the ratio for the pigment to epoxy resin is 4~6% around (more or less will be as per color effect).

for coloring for making designer floor , the ratio for the pigment to epoxy resin is 4~6% around (more or less will be as per color effect).

Top coating

:

2 options

:

1) 0.3kgs high hardness epoxy resin per square meters for for anti-scratch and glossy smooth effect;

2) 0.06kgs water based PU resin per SQ.M for very high hardness and anti-scratch.

Step 3: Preparing the Floor

1.

Seal the perimeter

of the floor by using silicone sealant or epoxy adhensive to fill big gap;

2.

Fill and cracks, holes or gaps

in the floor to create a flat, smooth surface ; For this step we used a small amount of the

epoxy primer

to mix with some Fumed Silica to create a epoxy filler ,then left this to fully harden;

3.After cure ,

sand smooth

any rough or high spots and clean the floor thoroughly ,if find anywhere is not sealed well,can apply another thin layer of primer or clear middle coating resin .

Step 4: Weighing, Mixing and Pigmenting the Resin

1.

Single color or multiple colours

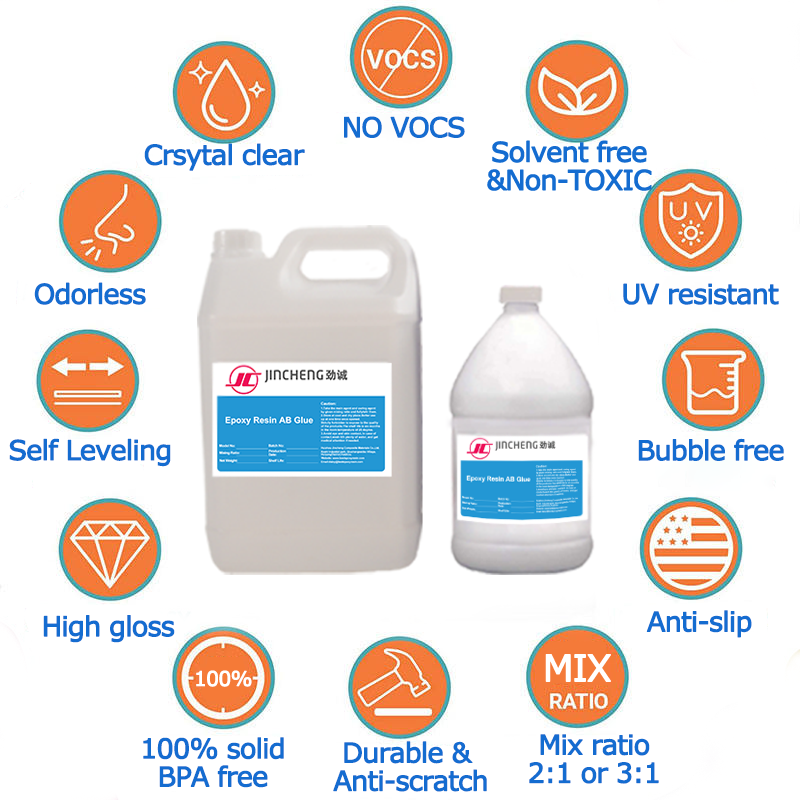

can be put to mix as per application area and projects design; 2.Lots of makers are using

metallic pigments to add effects like marbling

and we would always recommend thorough testing of a small panel to practise any effect you want to achieve before pouring the whole floor.

Step 5: Pouring & Curing the Resin

1.Our epoxy coating resin has excellent self-levelling properties, so will only require light working to ensure that it has complete coverage and a consistent thickness - then the resin will do the rest of the work;

2.A small spreader will be used for pushing the resin around any obstructions like pipework or a pillar, but for the bulk of the spreading it's best to use a notched squeegee for speed and efficiency;

3.For big area,suggest 2 or more people to help mix ratio and pour ;

4.Our

epoxy floor resin

is

well self-degassing

so the bubbles will pop on their own,if floor is not presealed well,also may have few small area bubble,in this case just to overcome this we quickly passed over the surface with a propane torch to burst them.

Step 6: The Finished Floor and Application

1.Whole processing will require 2 days around, the resin will be touch dry after 24hours, but should leave it much longer time before bring any furniture or heavy appliances;

2.Single color or blended colour floor by combining solid color or metallic pigmemts to achieve a unique appearance.It will be also work by adding marbling or veins with metallic pigments or conntrasting colours, using the resin as a clear coat over a decorative floor like pennies, flakes,3D stickers ,vinyl records, crushed glass,mosaics and much more are all possibilities.

Application

For Garage floor coating ,Industry floor coating ,Residential Floor coating ,Commercial floor coating and designer floors:showroom, shop,hotel ,or designer living space!

Factory Advantages

#Industry-leading factory ;

#High-transparent epoxy resin R & D and production for

20 years

;

#Over

10 years experience

exporting.

#Develop and manufacture

high quality

epoxy resin ,PU resin ,UV resin etc.;

#Plant area

20000 square meters

;

#Certificates:

SA8000

ISO9001.

#Reliable factory with

good reputation around the world

;

Why Choose Us

5 Stars Feedback from our clients

Certifications

Packing & Delivery

FAQ

Q1: What is the difference between floor paint and metallic floor?

A: The application of the two models are different. Floor paint is applicable to factories, underground parking lots and garages.Metallic floors are suitable for hotels, home, kitchens, tatto or hair salon etc. Floor paint resin is cheaper than metallic floor resin;

Q2: Will your products be scratch-resistant, anti-static, anti-slip ?

A: Yes , we will offer a special material for handling top;

Q3: After the pigment powder is mixed with resin, why is the color changed before and after curing ?

A: Because it will release heat after mixing resin and hardener, if the pigment powder mixed in is not good quality , it may change color;

Q4: After the pigment powder is mixed with resin and hardener, and then apply to floor coating , will the pigment sink before cure?

A: It may sink if use large articles of pigment powder .The solution is to make the thickness not more than 1mm or to add special additives to avoid sink;

A: The application of the two models are different. Floor paint is applicable to factories, underground parking lots and garages.Metallic floors are suitable for hotels, home, kitchens, tatto or hair salon etc. Floor paint resin is cheaper than metallic floor resin;

Q2: Will your products be scratch-resistant, anti-static, anti-slip ?

A: Yes , we will offer a special material for handling top;

Q3: After the pigment powder is mixed with resin, why is the color changed before and after curing ?

A: Because it will release heat after mixing resin and hardener, if the pigment powder mixed in is not good quality , it may change color;

Q4: After the pigment powder is mixed with resin and hardener, and then apply to floor coating , will the pigment sink before cure?

A: It may sink if use large articles of pigment powder .The solution is to make the thickness not more than 1mm or to add special additives to avoid sink;

Q5: Do you have manual instruction videos ?

A: Yes we have ,pls kindly contact our sales to send you;

Q6: If we have other special performance to be added into products ,will you customize for us ?

A: Yes we can , we have professional R& D team , who can do a model as per clients requirements, we can deliver new samples within 3 days.

Hot Searches