- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

sevenstars

-

Application:

-

pet bottle recycling washing, Waste plastic pet bottle recycling washing machine

-

Production Capacity (kg/h):

-

300 - 2000

-

Voltage:

-

380V or customised

-

Dimension(L*W*H):

-

according to the capacity

-

Power (kW):

-

255

-

Weight (T):

-

30

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

material:

-

stainless steel 304

-

main motor:

-

Siemens

-

PLC:

-

Siemens

-

Final PET flake water content:

-

less than 3%

-

Final product:

-

clean pet flake

-

delivery date:

-

60days

-

Production Capacity:

-

300-2000kg/h

-

Certification:

-

CE CE & ISO

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

2000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

sevenstars

-

Application:

-

pet bottle recycling washing, Waste plastic pet bottle recycling washing machine

-

Production Capacity (kg/h):

-

300 - 2000

-

Voltage:

-

380V or customised

-

Dimension(L*W*H):

-

according to the capacity

-

Power (kW):

-

255

-

Weight (T):

-

30

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

material:

-

stainless steel 304

-

main motor:

-

Siemens

-

PLC:

-

Siemens

-

Final PET flake water content:

-

less than 3%

-

Final product:

-

clean pet flake

-

delivery date:

-

60days

-

Production Capacity:

-

300-2000kg/h

-

Certification:

-

CE CE & ISO

-

Marketing Type:

-

Ordinary Product

Product Description

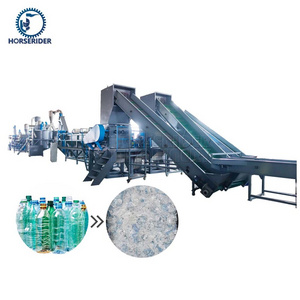

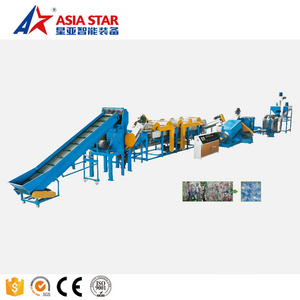

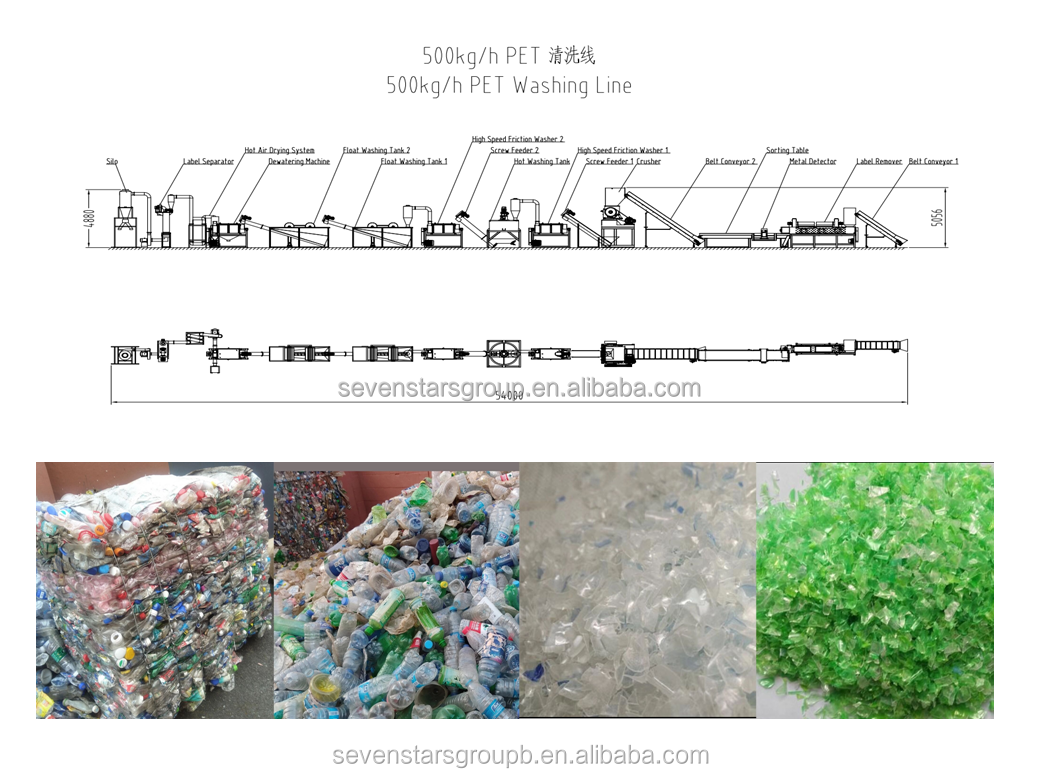

PET BOTTLE WASHING RECYCLING LINE

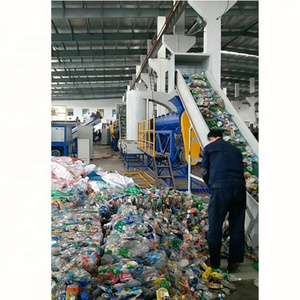

PET bottle washing recycling production line is used for recycling and washing PET plastic bottles, such as waste PET bottles, different beverage bottles such as mineral water bottles, Coke bottles, green tea bottles, Baby bottles, Milk bottles, oil bottles and other common plastic bottles in our daily life.

The line aims to recycle pet plastics in our everyday life to great extent and reduce environmental pollution. Meanwhile, the washing line can cater for various customers' production output and demands.

Capacity:

300 kg/h, 500 kg/h, 1000 kg/h, 1500-2000 kg/h, 3000 kg/h, 5000 kg/h, 1 ton and even more.

Application:

used PET bottles, water bottles, HDPE bottles, PP bottles and other common bottles in life

Specification:

general configuration as follows: bale opener(optional)--belt conveyor(several sets)-- trommel screen(optional)--label remover(several sets)--manual sorting table--plastic crusher(1-2 sets)--screw loader/screw friction loader(several sets)--hot washer--floating washing tank(several sets)--high speed centrifugal de-watering machine--hot air pipe drying system--label separator--silo

After-sale service:

Our company have a experienced installation team to provide professional installation guidance and training support.

|

capacity

(kg/h)

|

length of line

(meter)

|

manpower

|

power consumption

(kw/h)

|

working ways

|

|

300

|

about 25

|

5-10

|

negotiation

|

automatic

|

|

500

|

about 50

|

5-10

|

negotiation

|

automatic

|

|

1000

|

about 65

|

5-10

|

negotiation

|

automatic

|

|

1500

|

about 80

|

5-10

|

negotiation

|

automatic

|

|

2000

|

about 90

|

5-10

|

negotiation

|

automatic

|

|

5000

|

about 100

|

5-10

|

negotiation

|

automatic

|

Details of the production

* belt conveyor:

1. convey pet bottles from one machine to another

2. the width of the belt can be customized according to your needs. eg: 600 mm, 800 mm, 1000 mm and 1200 mm

* label remover:

This machine is mainly used to remove the PVC label and OPP label and other label from the bottle.

With new design, just by air sucking, no need to connect water. This is a key machine for PET bottle recycling line

Manual sorting table

This machine is used to sort out the PVC labels, bottle caps, paper, metal scraps and other dirty impurities from the bottles.

De-ironing machine is to remover the metal among the bottles and to protect the blades of plastic cruher, prolong the life of crusher blades

plastic crusher

This machine will crush the PET bottle into PET flake

high configuration(optional) PC800——37kw, PC1000——55kw, PC1200——75kw

screw loader&hot washer:

convey flakes into hot washer to wash PET flakes with specialized PET scraps washing detergent

high speed centrifugal de-watering machine

This machine is mainly used to clean the paper label, paper and other dirty on the surface of PET flake

Label separator

Removing little amount of label and dust in PET flakes

control all electrical apparatus elements of the washing line

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Jiangsu

|

|

Brand Name

|

sevenstars

|

|

Application

|

pet bottle recycling washing

|

|

Condition

|

New

|

|

Automatic Grade

|

Automatic

|

|

Production Capacity (kg/h)

|

|

|

Voltage

|

380V or customised

|

|

Dimension(L*W*H)

|

according to the capacity

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Multifunctional

|

|

Applicable Industries

|

Manufacturing Plant, PET bottles washing recycling

|

|

After-sales Service Provided

|

Field installation, commissioning and training

|

|

After-sales Service Provided

|

Engineers available to service machinery overseas

|

|

Application

|

Waste plastic pet bottle recycling washing machine

|

|

material

|

stainless steel 304

|

|

main motor

|

Siemens

|

|

PLC

|

Siemens

|

|

Final PET flake water content

|

less than 3%

|

|

Final product

|

clean pet flake

|

|

delivery date

|

60days

|

|

Weight

|

according to the complete line

|

|

Production Capacity

|

300-2000kg/h

|

|

Certification

|

CE CE & ISO

|

Packing & Delivery

plastic film and plywood case for Waste plastic pet bottle recycling washing machine

Hot Searches