- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YD

-

Model Number:

-

YD-FY-001

-

Dimension(L*W*H):

-

customized

-

Weight:

-

2000-8000KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Use for:

-

emulsion paint,internal,external wall paint

-

Output:

-

1-4ton/h

-

Technical:

-

Mature technical and rich experience

-

Control:

-

PLC

-

Machine Type:

-

Coating Machine

-

Product Type:

-

Paint

-

Certification:

-

ISO9001,CE, CE ISO

-

Machine material:

-

Stainless steel

-

Warranty:

-

1 year

-

MOQ:

-

1 set

Quick Details

-

Packaging Material:

-

Metal, Wood

-

Voltage:

-

220V/380/420

-

Power:

-

2.2-22KW

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

YD

-

Model Number:

-

YD-FY-001

-

Dimension(L*W*H):

-

customized

-

Weight:

-

2000-8000KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Use for:

-

emulsion paint,internal,external wall paint

-

Output:

-

1-4ton/h

-

Technical:

-

Mature technical and rich experience

-

Control:

-

PLC

-

Machine Type:

-

Coating Machine

-

Product Type:

-

Paint

-

Certification:

-

ISO9001,CE, CE ISO

-

Machine material:

-

Stainless steel

-

Warranty:

-

1 year

-

MOQ:

-

1 set

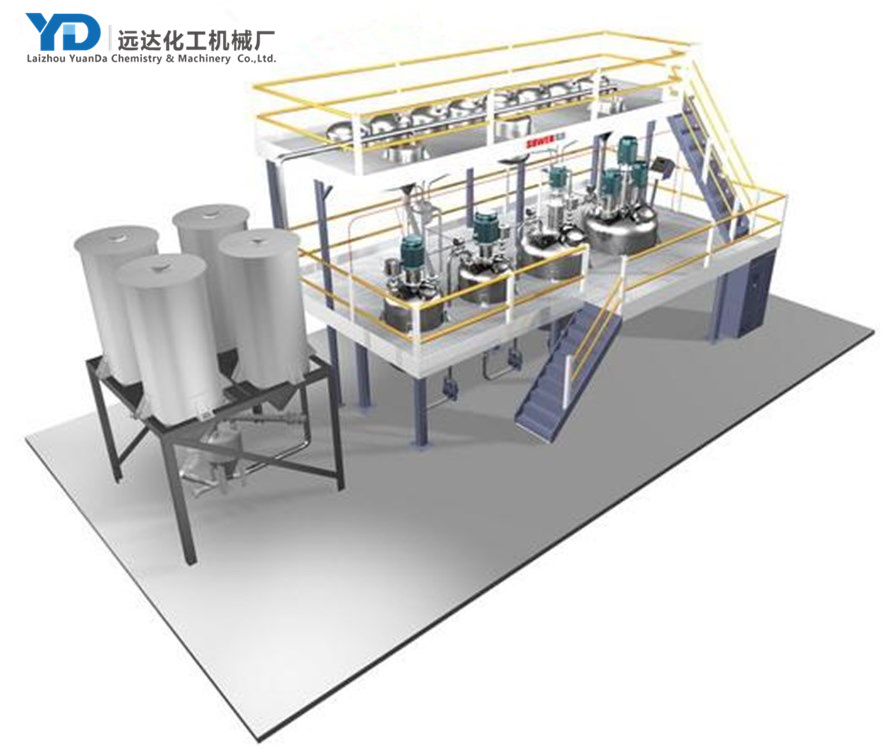

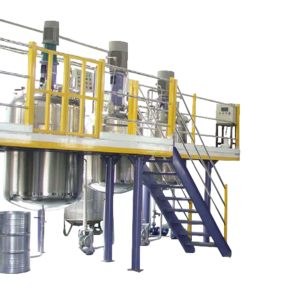

1. Annual production up to 300~600 tons, that is 0.9 ton per 4 hours, can manufacture oiliness painting;

2. Mirror-surface polishing for all stainless steel parts makes them delightful and shining, vacuum operation with no dust and clean worksite;

3. Good man-machine engineering design, only two workers needed for operation;

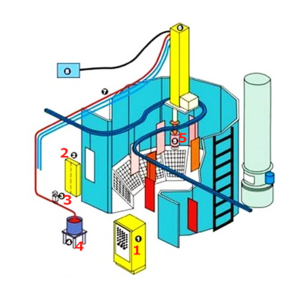

4. Manufacturing process is designed by Macromolecule Research Institute of Anhui University and No.3 Research Institute of Chemical Industry, China. Equipment set includes 7 sub-systems, which are 1) vacuum material adding system, 2) pressure discharging and filtration system, 3) slurry producing and color mixing system, 4) cooling system, 5) piping system, 6) electrical control system and 7) operation platform;

5. Buying without foregift, customer can bring raw material to our company and run test operation in workshop. Equipment can be shipped immediately after checking and acceptance of the user;

6. 12 months warranty for free charge, be responsible for servicing in equipment working life.

Size: 5m length × 4m width × 3.3m height

Total power consumption: 20kW