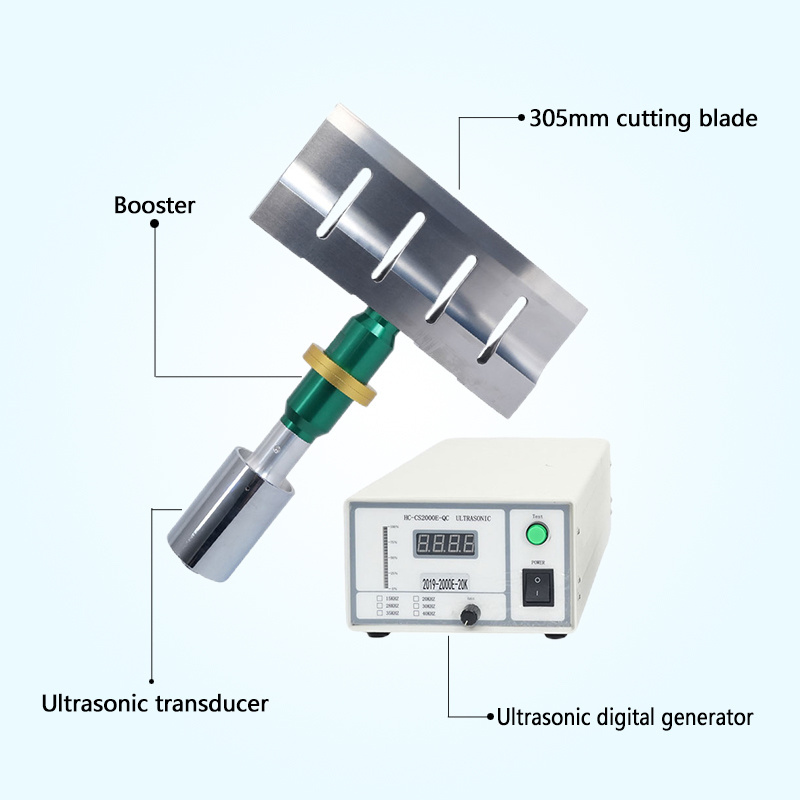

The ultrasonic cake cutter typically consists of a handheld or machine-mounted unit that houses the ultrasonic generator and the

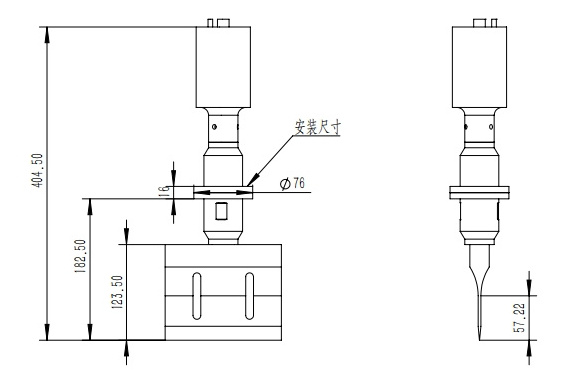

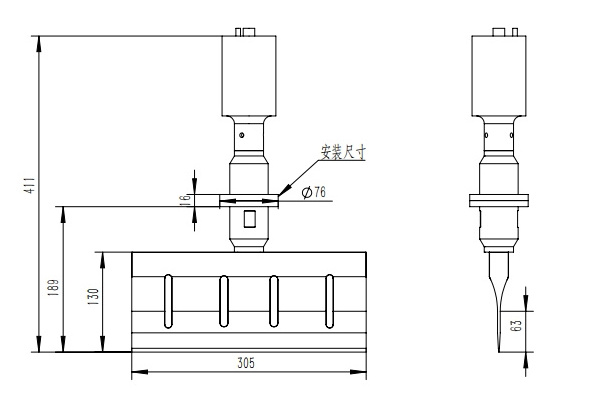

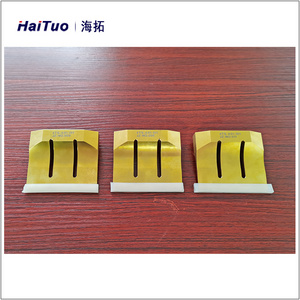

cutting blade.

The generator produces an electrical signal that is converted into mechanical oscillations by a piezoelectric transducer.

These oscillations are then transferred to the cutting blade, causing it to vibrate at ultrasonic frequencies.