- Product Details

- {{item.text}}

Quick Details

-

Wire size:

-

2.078.0mm

-

Axis:

-

10

-

Wire feeding value:

-

Max.10000.00 Min.0.01

-

Feeding length number:

-

3pairs

-

Wire turning angle:

-

Unlimited

-

Platform Lifting Height:

-

+25~-120mm

-

Twisting head lift height:

-

+25~-180mm

-

Left to right moving range:

-

Left:100mm Right:50mm

-

Feeding front and back moving range:

-

Front:300mm Back:100mm

-

Total output power of servo motors:

-

24.2kw

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BoBo

-

Weight (KG):

-

3800

-

Wire size:

-

2.078.0mm

-

Axis:

-

10

-

Wire feeding value:

-

Max.10000.00 Min.0.01

-

Feeding length number:

-

3pairs

-

Wire turning angle:

-

Unlimited

-

Platform Lifting Height:

-

+25~-120mm

-

Twisting head lift height:

-

+25~-180mm

-

Left to right moving range:

-

Left:100mm Right:50mm

-

Feeding front and back moving range:

-

Front:300mm Back:100mm

-

Total output power of servo motors:

-

24.2kw

Product Description

Cnc Wire Bending Machine

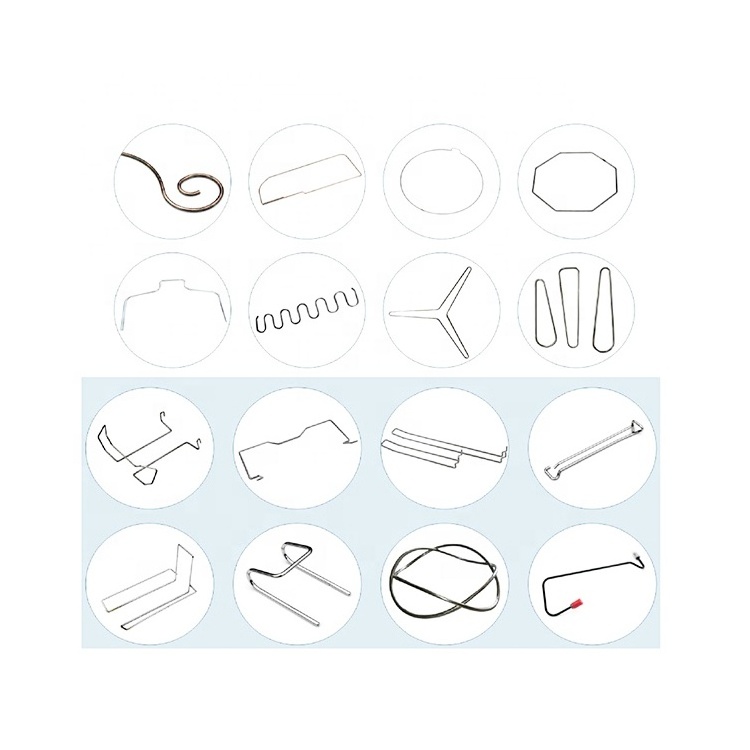

Cnc wire bending machine is to produce kinds of 2D and 3D wire forms expertly with high precision and fast speed. Adopts Japanese branded servo motor and screen display with high quality controller. Easy operation and fast turn-key.

Product details

Finished Product

Features

1.

The external torsion head can be raised and lowered individually.

2.

The torsion head as a whole can be offset from side to side.

3.

The Mt. County box can be moved back and forth.

4.

Cut to move back and forth.

5. 3-4 pairs feeding roller, feeding motor fixed on the bottom base, so as to decrease the feeding box weight, that wire rotating is more fast and light, turning angle is more precise and stable. Twisting head is designed in copper tube transport, more stable and stronger than bearing transfer.

Specification

|

Wire size

|

2.0-7.0mm

|

|

Axis

|

10

|

|

Wire feeding value

|

Max.10000.00 Min.0.01

|

|

Feeding length number

|

3pairs

|

|

Wire turning angle

|

Unlimited

|

|

Platform Lifting Height

|

+25~-120mm

|

|

Twisting head lift height

|

+25~-180mm

|

|

Left to right moving range

|

Left:100mm Right:50mm

|

|

Feeding front and back moving range

|

Front:300mm Back:100mm

|

|

Total output power of servo motors

|

24.2kw

|

|

Automatic decoiler

|

500KG

|

|

Machine size

|

380x152x160cm

|

|

Machine weight

|

3800kg

|

Packing and Shipping

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

About Us

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc

3. Q: What is the payment term A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, DA, D/P etc

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 30 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

Hot Searches