- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V415V

-

Dimension(L*W*H):

-

1.85*0.75*1.45m

-

Weight:

-

650 KG

-

Features:

-

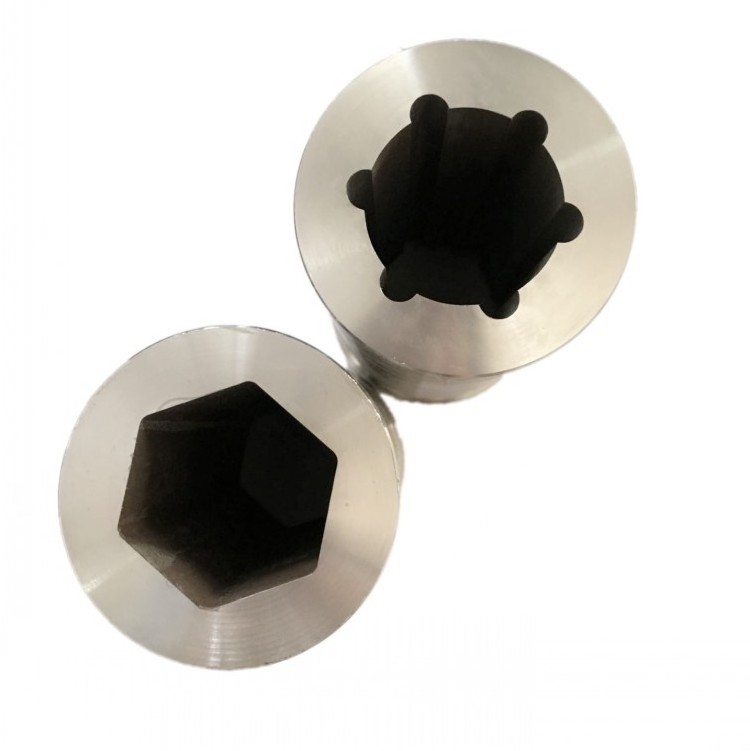

Round, square, hexagonal sticks with holes inside

-

ITEM:

-

Charcoal Briquette Machine

-

Raw material:

-

wood chips,sawdust,branches,straw,peanut shell etc.

-

Briquette Shape:

-

Hexagonal Hollow Cylindrical

-

Function:

-

Sawdust Briquette Making Machine

-

Raw material size:

-

Below 3mm

-

Keyword:

-

Sawdust Briquettes Charcoal Machine

-

Product name:

-

biomass sawdust briquette making machine

-

raw material moisture:

-

8%-10%

-

Briquette diameter:

-

50-80 mm

-

Capacity:

-

260-350kg/h

Quick Details

-

Application:

-

making wood briquette

-

Production Capacity:

-

350kg/h

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V415V

-

Dimension(L*W*H):

-

1.85*0.75*1.45m

-

Weight:

-

650 KG

-

Features:

-

Round, square, hexagonal sticks with holes inside

-

ITEM:

-

Charcoal Briquette Machine

-

Raw material:

-

wood chips,sawdust,branches,straw,peanut shell etc.

-

Briquette Shape:

-

Hexagonal Hollow Cylindrical

-

Function:

-

Sawdust Briquette Making Machine

-

Raw material size:

-

Below 3mm

-

Keyword:

-

Sawdust Briquettes Charcoal Machine

-

Product name:

-

biomass sawdust briquette making machine

-

raw material moisture:

-

8%-10%

-

Briquette diameter:

-

50-80 mm

-

Capacity:

-

260-350kg/h

rice husk wood briquette machine sawdust briquetting press sawdust briquette charcoal making machine

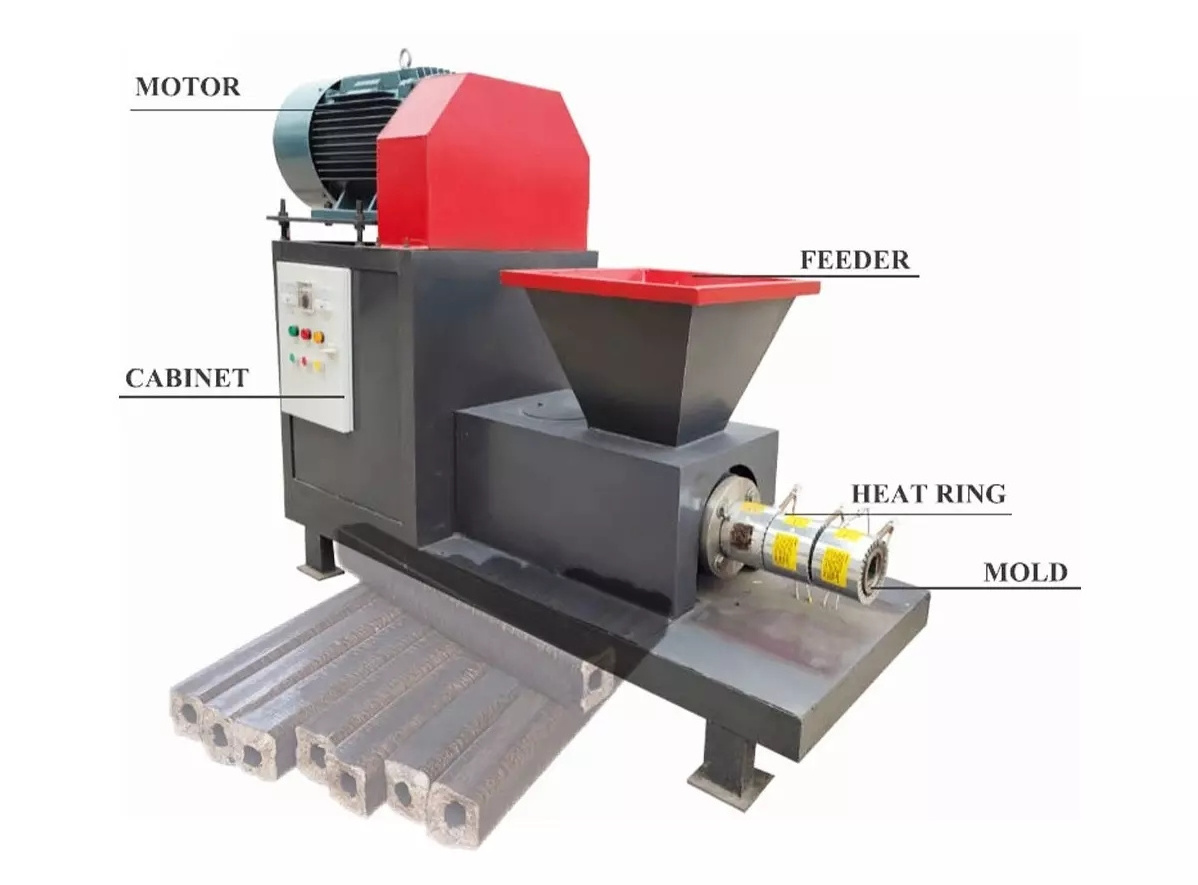

1. Briquette Machine can make stick shape wood briquette of different diameter and different shape from agro-forest wasted.

Fire wood sawdust briquette machine also called biomass briquette machine and sawdust briquette machine, is used to convert sawdust into charcoal stick as biofuels ,used to heat boiler, fireplace, etc for warm in house.

Feature:

-

1. High Pressure and High Briquetting Efficiency

AOLS briquetting machine is specially designed with four rollers that can enlarge equipment pressure and improve briquette making efficiency. In addition, hydraulic device can be alternative if required.2. Energy Saving and Environment Friendliness

The press briquette machine is mainly used to press powdery industrial wastes and dust to regularly shaped briquettes for further usage, reducing dust pollution and improving resource utilization ratio. It can run in low power, thus saving much energy. Thanks to enclosed construction, the briquetting machine will not cause air and noise pollution.3. Wide Application and Low Requirement for Working Environment

The industrial waste processing machinery is suitable for use in all countries around the world. According to different conditions of every country, it can be reasonably adjusted for normal use. Additionally, it can be used in all kinds of severe environment, such as extremely cold weather, high temperature, plateau, etc.

4. Easy Installation and Simple Transportation

This briquette machine is designed with high strength steel plate as its support, enabling it to be directly used on hard flat area without having to build a foundation. In addition, it is easy for users to transfer and transport this equipment.

5. Simple Operation and Easy Maintenance

The industrial fuel briquetting machine is available in semi-automatic and full automatic design as per customer’s requirements, thus ensuring less labor and simple operation. In daily use, you only need to do regular maintenance according to the maintenance instruction.

|

Machine Model |

|

|

Power |

|

|

50mm |

|

|

Machine Dimension |

1.85*0.75*1.45(m) |

|

Weight |

|

|

Calorific value ( kcal/kg) |

6000-7500kcal/kg |

|

Specific gravity( kg/m³) |

1200~1300kg/m³ |

|

Raw Materials |

Sawdust, wood chips, biomass, etc |

|

Briquette Shape |

Raw Material

( Size: 3-5mm Moisture Content : 8%-12% )

|

1.straw 2.sugarcane residue 3.coffee husk 4.cotton stalks 5.tobacco waste 6.mustard stalk 7.jute waste 8.bamboo dust 9.tea waste 10.wheat waste 11.palm husk 12.soybeans husk 13.rice husk 14.wood chips 15.agro waste |

Working Principle:

This wood briquette making machine uses the intrinsic attributes of the wood material, by spiral extruding at high temperature under high pressure, wood element in wood material becomes plastic and makes the fine fiber combine, and then stick solid fuel is formed.

Wood Briquette Production Plant

Step 1- Crushing:

Crush the raw materials into small pieces (3-5mm).

All type of Agro-Forestry waste can be used such as sawdust, wood chips, crop stalks, etc.

PS1: If your raw material size is less than 5mm, you can ignore the crush process.

PS2:You can also carbonize the material without crushing and briquetting

Step 2- Drying:

Dry the crushed materials to reduce the moisture content below 8-12%;

PS: if the moisture of raw material is 8-12%, you can ignore the drying process

Step 3- Briquetting.

- Final products from metal chip briquetting machine:

-

Square, round, hexagonal, pentagon ( With/without edge)

Hollow

Diameter: 50,80mm

Inside diameter: 15-20mm

Length: 20-50cm

Specific Gravity: 1200-1300kg/m3

Calorific value:4000-4800kcal/kg

Step 4- Carbonization.

Carbonizing briquette log into charcoal without smoke,Tasteless.

No any open fire, Totally dry distillation

1.The Inner Former can be used for 1-2 years.The former is made from a whole steel bar through a water jet cutting system so that the internal surface is smooth. Therefore, it’ll be easier to form and save energy.

This is why the finished produces such as sawdust briquettes are smooth.

2.We adopted three heating rings which are made from thick copper wires and are ceramic inside.

Our biomass briquette machine adopts a durable material (high hardness alloy steel) to make the shaft.

3.We use a different process then what is normally used to make the screw shaft. The screw shaft is manufactured with a milling machine which guarantees that the distance between every screw is the same, and the angle of every screw is the same.

- Carbonization Machine size & weight of Whole sets machine

Outer stove diameter 1890mm /outer stove

Inner pot diameter 1500mm/1450mm/1400mm

Loading Size 2.1*2.2*2.1meters. Weight 3000kg

Note : 1*40GP container can hold 4 whole sets machine

- Carbonization Machine Materials

Mn High temperature resistant plate 6-12mm according different part

- Fuel consume

20-30 kg firewood or 15 kg liquefied gas per time

Only pre-heating need consume fuel, pre heating time is about 80-100minutes

- Carbonization Time

Wood logs ( 8-10hours), wood briquettes (8hours),

coconut shell (6hours)

- About cooling

After carbonizing, we need to take the inside pot out, let it cool by natural way, the longer cooling time the better for charcoal quality

Application For Charcoal Briquette

- Used as bio fuels for boiler

- For Stove, Home heating

- Used BBQ charcoal for Barbecue

- Fuels for Europe country Fireplace etc.

From the design, we will do every step carefully to satisfy clients to the best.

- Manufacturer Service

Provide goods based on customer's need.

Can print customer Logo on the machine according the customer.

We provide all spare parts for all machines in lifetime use.

- Sales Service

Price Term: Price can be based on EXW,FOB,CFR,CIF,DDU etc.

Payment Term:T/T. L/C, Western Union ,Credit Card,Pay from Alibaba.

Guarantee terms:Quality guarantee term for one year,exclude wear part.

- Online Service

Timely response online by whatsapp,Trademanager or Wechat.

Keep in touch by email, phone.

- Shipping Service

Transportation:Shipping by LCL,FCL by sea transport.

Packing:Packing by export wooden box or loading by container.

Delivery time:3-7 days ,after deposit,Special circumstance will notify.

Shipping:we can be responsible for the shipping ,also accept client shipping agent.

Shipping port:Tianjin,Qingdao,Shanghai,Guangzhou etc.