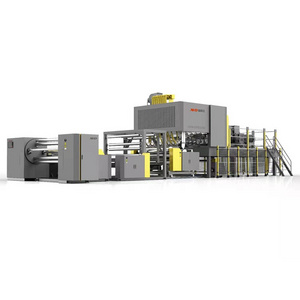

(1)Reasonably solid square steel frame: Panel 30mm thick, adopt specular paint, 6 surfaces processing, solid cage with 60 * 60mm square steel in module design, the base frame with square tube 120mm × 120mm, 18mm thick bottom plate, 6 surface processing also ,widening after gearbox for repair. Spliced type main board by screw, make sure the high efficiency .

(2)

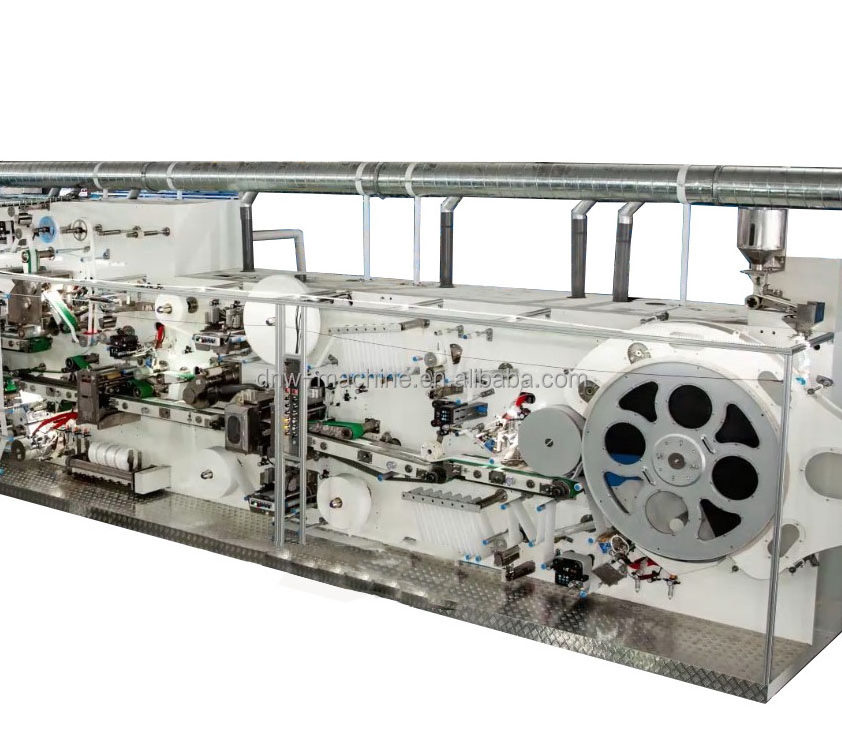

Glue applicators put on the 2nd platform, shorten the glue supply distance.

(3)

The main air suction bucket is installed with negative pressure display; the air scoop driven wheel is installed with quick fixture to facilitate the removal of the belt; the lower side of the conveyor belt above the material is installed with support plate to prevent the polymer and foreign matters from falling and polluting the lower material (the belt specification is labeled for maintenance).

(4)

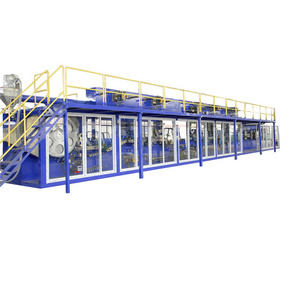

The back doors of the machine has sound proof foam