- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

FLQ640H-16P

-

Brand Name:

-

Fols

-

Product Name:

-

Pneumatic V control ball valve

-

Size Range:

-

1/2"~8", DN25~500

-

Operating Pressure:

-

1.6MPa

-

Angle of Rotation:

-

90° ±4°

-

End Connection:

-

Flanged

-

Body Materials:

-

SS304, SS316, SS316L

-

Number of Ways:

-

2 Way

-

Acting Mode:

-

Double Acting, Spring Return (Single Acting)

-

Applicable Media:

-

Control of Water, Air, Gas, Oil, Liquid

-

Optional Actuation:

-

Handlever, Electric Actuated, or Pneumatic Actuated

Quick Details

-

Port Size:

-

Standard, DN25~500

-

Warranty:

-

1 year

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

FLQ640H-16P

-

Brand Name:

-

Fols

-

Product Name:

-

Pneumatic V control ball valve

-

Size Range:

-

1/2"~8", DN25~500

-

Operating Pressure:

-

1.6MPa

-

Angle of Rotation:

-

90° ±4°

-

End Connection:

-

Flanged

-

Body Materials:

-

SS304, SS316, SS316L

-

Number of Ways:

-

2 Way

-

Acting Mode:

-

Double Acting, Spring Return (Single Acting)

-

Applicable Media:

-

Control of Water, Air, Gas, Oil, Liquid

-

Optional Actuation:

-

Handlever, Electric Actuated, or Pneumatic Actuated

Product Description

|

Size Range

|

1/2"~8", DN25~500

|

|

Acting Mode

|

Double Acting, Spring Return (Single Acting)

|

|

Operating Pressure

|

1.6MPa

|

|

Air Supply Pressure

|

2.5 to 8 bar

|

|

Lifespan

|

1,000,000 (1 Million) Times

|

|

Angle of Rotation

|

90° ±4°

|

|

Body Material

|

SS304, SS316, SS316L

|

|

Sealing Material

|

PTFE: -30°C~180°C, PPL: -30°C~250°C

|

|

Number of Ways

|

2 Way

|

|

End Connection

|

Flanged

|

|

Applicable Media

|

Control of Water, Air, Gas, Oil, Liquid

|

|

Optional Actuation

|

Handlever, Electric Actuated, or Pneumatic Actuated

|

|

Optional Accessories

|

Namur Solenoid Valve, Limit Switch, F.R.L, Position Indicator, Manual Device

|

|

Application

|

Food & Beverage, Water & Wastewater, Ultra Pure Water, Desalination, Chemical,Textile, Pharmaceutical, Pulp & Paper

|

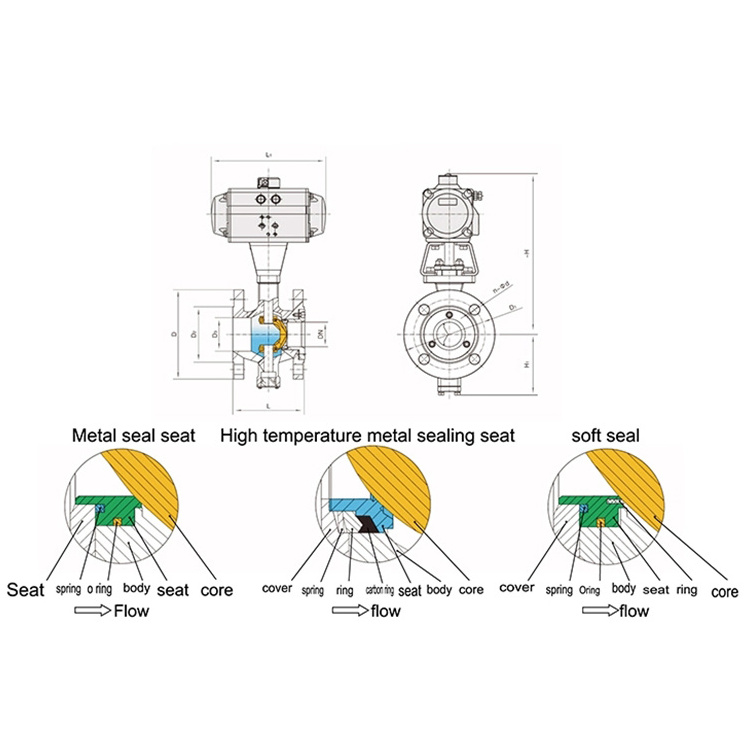

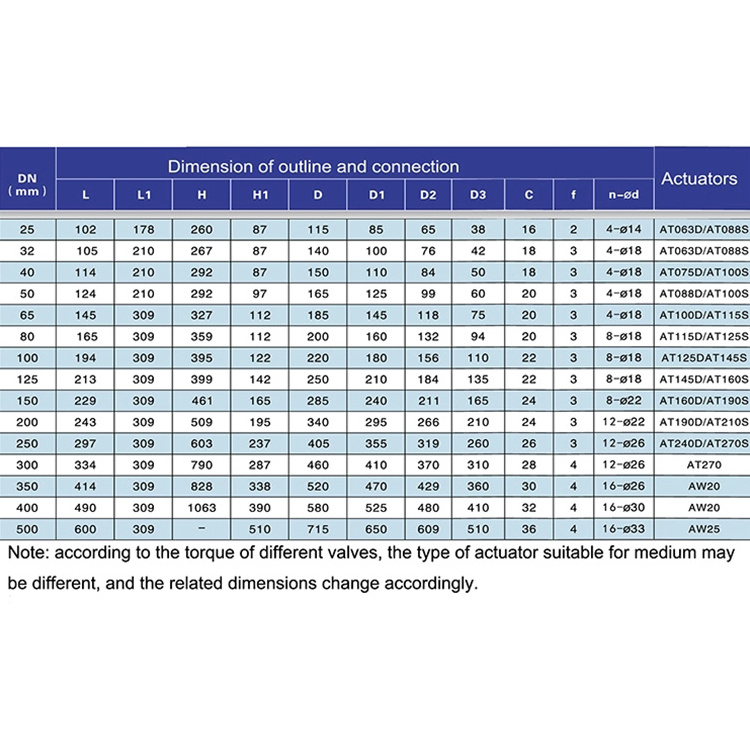

Specification

Pneumatic V control ball valve is equipped with FOSD series pneumatic actuator to adjust the pressure, flow, temperature, liquid level and other parameters. The valve core is opened with a V type incision, and the shear force is generated by the relative rotation of the hard seal seat, and the fiber can be cut off to prevent the death of the card. It has the characteristics of large circulation capacity, high adjusting precision, large adjustable ratio, good sealing and light weight. It is suitable for most occasions except small caliber, corner type and three way connection. It's the best product to replace imported products, especially for mud and fiber medium, as well as medium containing small solid suspension. It is widely used in the automation system of paper making, sugar making, petroleum, chemical, metallurgy, air conditioning, fire protection and water supply and drainage.

Features

2. Operation torque small, easy operation.

3. Mounted in any position, and easy maintenance.

4. The seal part can be replaced, zero leakage of reliable seal performance.

5. The seal material anti-aging, corrosion resistance, long life and other characteristics.

Design and Manufacturing Standards

Connection Standard: JB/T 79.1-1994 ASME B16.10

Structure Length: GB/T12221-2005 ASME B16.5

Pressure Testing: GB/T13927-2008

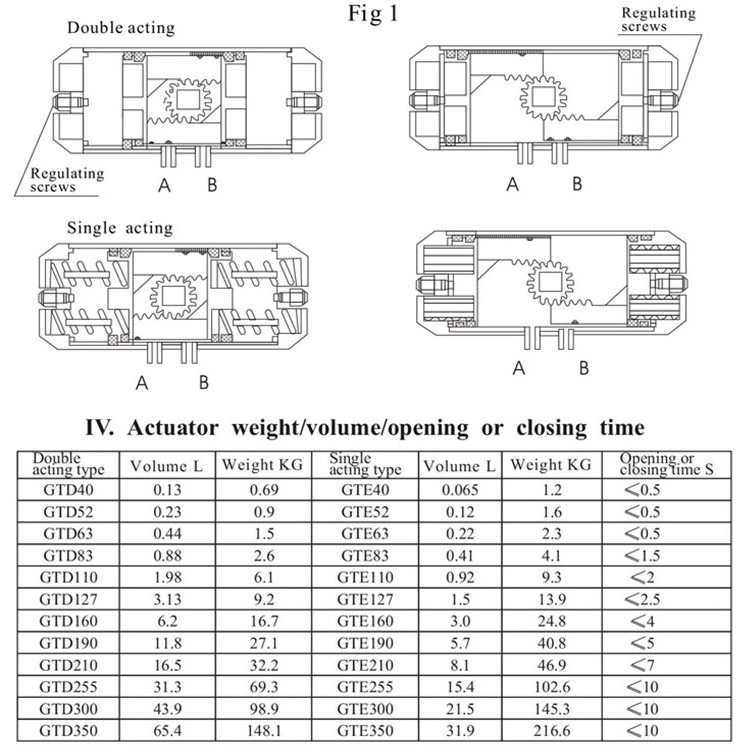

Pneumatic Actuator

Transmission structure principles

When the compressed air enters the pneumatic actuator through Nozzle A (as shown in Fig 1), the air will drive the double piston straightly moving toward two ends ( cylinder head end) and the piston rack will drive the gear of the rotary shaft by 90 degrees counter-clockwise. In this case, the valve will be opened. At this moment, the air in both ends of pneumatic actuator is discharged through Nozzle B. On the contrary, when the compressed air entered both ends of the pneumatic actuator through Nozzle B (as shown in Fig 1), the air will drive the double piston to straightly move towards the middle position and the piston rack will drive the gear of the rotary shaft by 90 degrees clockwise. In this case, the valve is closed. At this moment, the air in the middle of the pneumatic actuator is discharged through Nozzle A. What is aforementioned is the transmission principle.

According to users' needs, the pneumatic actuatorcan be equipped with transmissio.

Recommend Products

Hot Searches