- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BCAM

-

Single Pulse Energy:

-

1000w 2000w

-

Pulse Width:

-

0.5~10ms

-

Wavelength:

-

1070nm

-

Focal Spot Diameter:

-

0.2 ~ 2.0 mm

-

Dimensions:

-

1083*810*1300mm

-

Weight (KG):

-

200 KG

-

Marketing Type:

-

New Product 2022

-

Product name:

-

top fiber laser welder supply 1000w laser welding machine for sale

-

Laser source:

-

RECI

-

Laser power:

-

1000W 1500W 2000W Optional

-

Application material:

-

Aluminum Stainless Steel Carbon Steel

-

Cooling method:

-

Water Cooliing

-

Laser type:

-

Continuous Fiber Laser

-

Model:

-

Automatic Laser Spot Welding Machine

-

welding speed:

-

1-120mm/s

-

after-sales service:

-

Online support, Video technical support

-

certification:

-

CE ISO

Quick Details

-

Max. Output Power:

-

2000w

-

Use:

-

Matel Welding

-

Laser Source Brand:

-

RECI

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BCAM

-

Single Pulse Energy:

-

1000w 2000w

-

Pulse Width:

-

0.5~10ms

-

Wavelength:

-

1070nm

-

Focal Spot Diameter:

-

0.2 ~ 2.0 mm

-

Dimensions:

-

1083*810*1300mm

-

Weight (KG):

-

200 KG

-

Marketing Type:

-

New Product 2022

-

Product name:

-

top fiber laser welder supply 1000w laser welding machine for sale

-

Laser source:

-

RECI

-

Laser power:

-

1000W 1500W 2000W Optional

-

Application material:

-

Aluminum Stainless Steel Carbon Steel

-

Cooling method:

-

Water Cooliing

-

Laser type:

-

Continuous Fiber Laser

-

Model:

-

Automatic Laser Spot Welding Machine

-

welding speed:

-

1-120mm/s

-

after-sales service:

-

Online support, Video technical support

-

certification:

-

CE ISO

Product Description

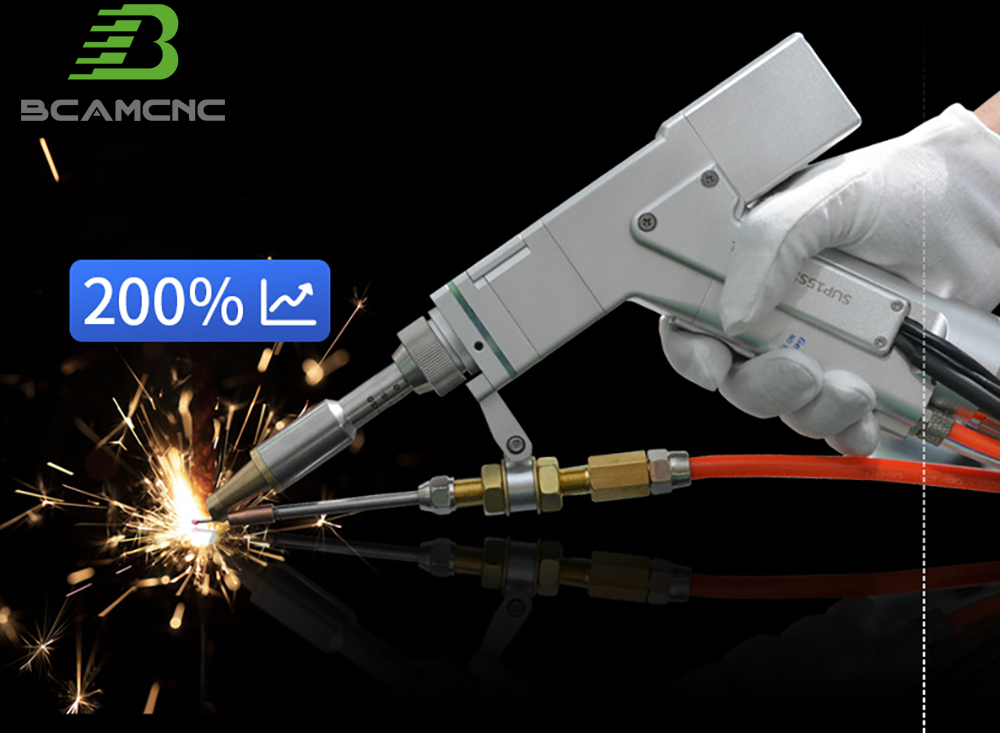

Product advantage

1.

Fast welding speed

, 2-10 times faster than traditional welding

2.

Smooth and even weld seam

, no bubbles, large welding depth, no grinding

3.

Solid welding

, no deformation, no blackening

4. Can be used according to the processing needs of

spot welding, butt welding, stack welding

and other modes

5.

Automatic fillet welding

, less welding consumables

Product Introduction

BCAMCNC handheld fiber laser welding machine, using the latest type of fiber laser, using the

industry's precision welding head

, with

simple operation, beautiful weld seam, fast welding speed

, the advantages of no consumables, a breakthrough in the original table limitations, welding at any angle, adjustable welding seam width, automatic wire feeding, simple operation, welding in stainless steel, iron bars, galvanized plate and other metal materials,

can replace the traditional argon arc welding

, electric welding and other processes.

|

Machine Model

|

BCW1000W

|

BCW1000W

|

BCW1500W

|

BCW2000W

|

|||

|

Operating Mode

|

Continuous/Modulation

|

|

|

|

|||

|

Laser Wavelength

|

1064nm

|

|

|

|

|||

|

Power Requirements

|

220V/380V

|

|

|

|

|||

|

Operating Environment Temperature Range

|

15-35℃

|

|

|

|

|||

|

Working Environment Humidity Range

|

<70% No Condensation

|

|

|

|

|||

|

Welding Thickness Range

|

0.5-0.8MM

|

|

|

|

|||

|

Welding Line Requirements

|

≤0.5mm

|

|

|

|

|||

|

Welding Speed

|

0-120mm/s

|

|

|

|

|||

|

Machine Size

|

1190×1100×650mm

|

|

|

|

|||

product details

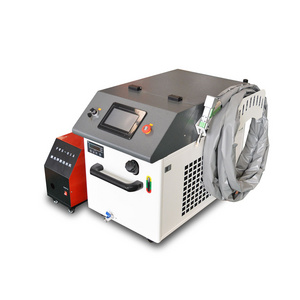

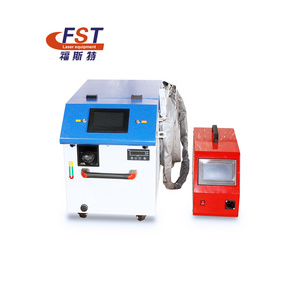

Machine appearance

*Integrated cabinet, integrated design

*Small footprint and easy to use

*Strong comprehensive performance and wide application fields

Swing welding head

*Galvanometer width adjustable, bead width 0.5-6mm

*Dedicated welding tip for welding at any position and angle

*Infrared positioning, more accurate welding position

Raycus Laser source:

Optional: JPT, GW, MAX, IGP laser generator

Water Chiller

High cooling rate, which can weld fine weld structure and good joint performance.

Control System:

*LCD touch screen, good interactive control system

*Preset multiple process modes to

*meet different process requirements

*Preset multiple security alarms, more secure and reliable

Wire feeding device (optional)

*Automatic wire feeding device *Software control, adjustable wire feed speed *Fill welds and

increase welding strength

increase welding strength

laser welding video

Applications&Samples

✦Applicable Materials:

BCAMCNC laser welding machine Application in Stainless steel, Carbon steel, Aluminum, Copper materials, etc.

✦Applicable industry

Can be widely used in cabinets, kitchen, staircase elevator, shelf, oven, stainless steel door and window

guardrail, distribution box, stainless steel home and other industries complex and irregular welding procedures

Packing & Delivery

1

.

Anti-collision package edge

:

All parts of the fiber laser welding machine are covered with some soft materials, mainly the use of pearl wool .

2 . Fumigation wooden box :Our wooden box is fumigated, do not need to check the wood, saving the transport time.

3. Whole film packaging machine : Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust.

4 . Wooden box at the bottom of a solid iron socket for easy handling.

2 . Fumigation wooden box :Our wooden box is fumigated, do not need to check the wood, saving the transport time.

3. Whole film packaging machine : Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust.

4 . Wooden box at the bottom of a solid iron socket for easy handling.

product advantage

* Various welding of non-standard metal parts, manual welding is more

flexible

;

* Perfect welding quality , small deformation, high penetration, no weld penetration ;

* Various welding process methods , spot welding, seam welding, and stitch welding Etc.;

* High welding efficiency , replacing traditional TIG welding equipment;

* Maximum welding cost, no consumables, energy saving and environmental protection .

* Perfect welding quality , small deformation, high penetration, no weld penetration ;

* Various welding process methods , spot welding, seam welding, and stitch welding Etc.;

* High welding efficiency , replacing traditional TIG welding equipment;

* Maximum welding cost, no consumables, energy saving and environmental protection .

After-sales service

We will give you

3 years warranty

, so you don't have to worry about the after-sales.

We will also send you new parts if there's any parts broken by non-human issues.

We will also send you new parts if there's any parts broken by non-human issues.

Hot Searches