- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

FORWARD

-

Voltage:

-

380V 50HZ 3P OR Customized

-

Dimension(L*W*H):

-

9 meters*1.2 meters*1.5 meters

-

Weight:

-

6000 kg

-

Marketing Type:

-

competitive price

-

Main frame:

-

350mm/400mm H-Beam

-

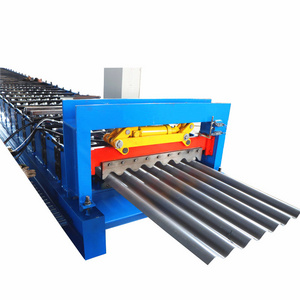

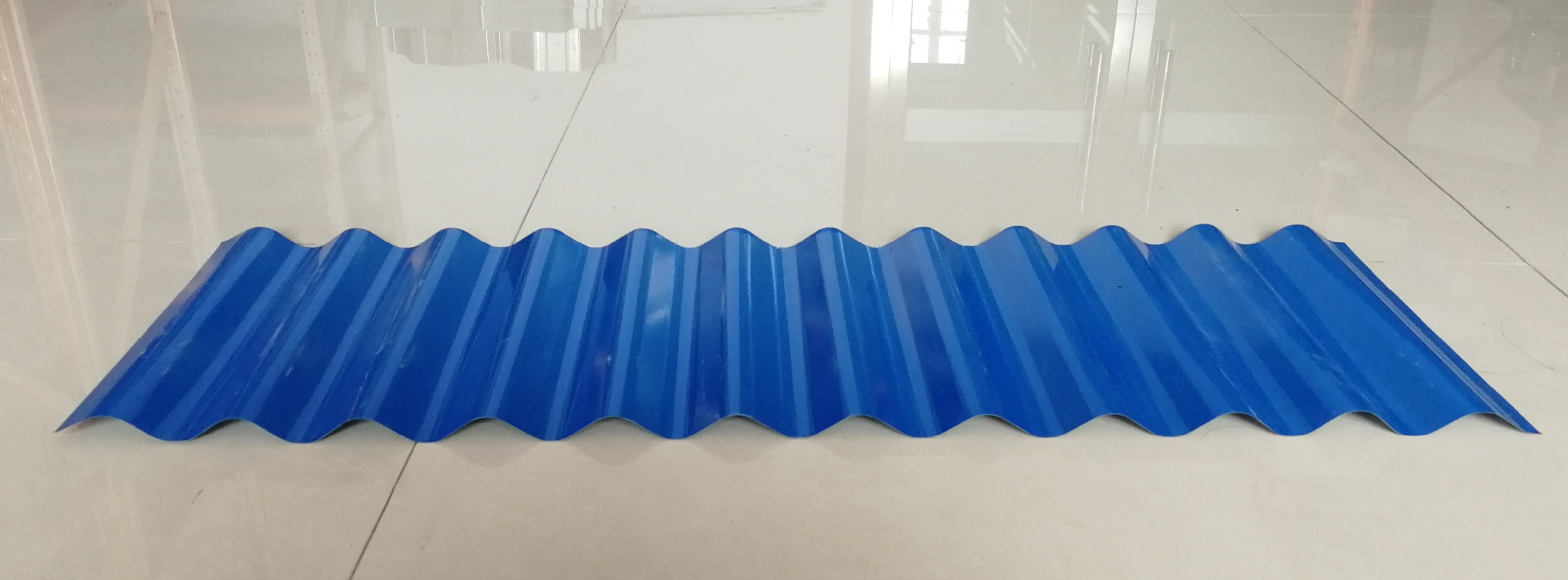

Machine type:

-

Metal roof Roll Forming Machine

-

Rolling thickness:

-

0.3-0.8mm

-

Material:

-

PPGI GI ALUZINC

-

Certification:

-

CE BV STV ISO

-

Profiles:

-

Metal Roof Forming Machine

-

Cutting type:

-

Hydraulic Cutting

-

Cutting blade material:

-

Cr12 Mov Steel

-

Plc:

-

DELTA(TAIWAN)or Mitsubishi(JAPAN)

-

Need container:

-

1*20 Feet

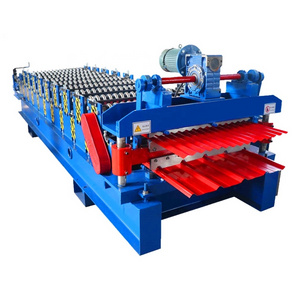

Quick Details

-

Type:

-

roof tile roll forming machine

-

Tile Type:

-

PPGI/GI/GL

-

Production Capacity:

-

10-15M/MIN

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

FORWARD

-

Voltage:

-

380V 50HZ 3P OR Customized

-

Dimension(L*W*H):

-

9 meters*1.2 meters*1.5 meters

-

Weight:

-

6000 kg

-

Marketing Type:

-

competitive price

-

Main frame:

-

350mm/400mm H-Beam

-

Machine type:

-

Metal roof Roll Forming Machine

-

Rolling thickness:

-

0.3-0.8mm

-

Material:

-

PPGI GI ALUZINC

-

Certification:

-

CE BV STV ISO

-

Profiles:

-

Metal Roof Forming Machine

-

Cutting type:

-

Hydraulic Cutting

-

Cutting blade material:

-

Cr12 Mov Steel

-

Plc:

-

DELTA(TAIWAN)or Mitsubishi(JAPAN)

-

Need container:

-

1*20 Feet

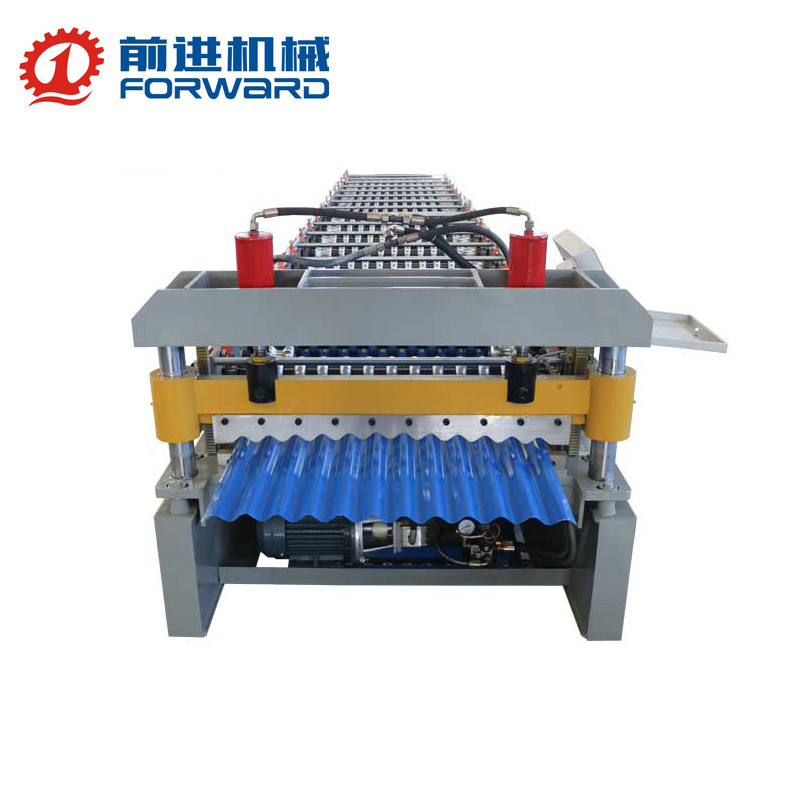

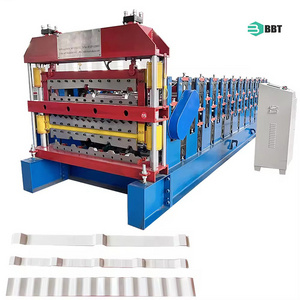

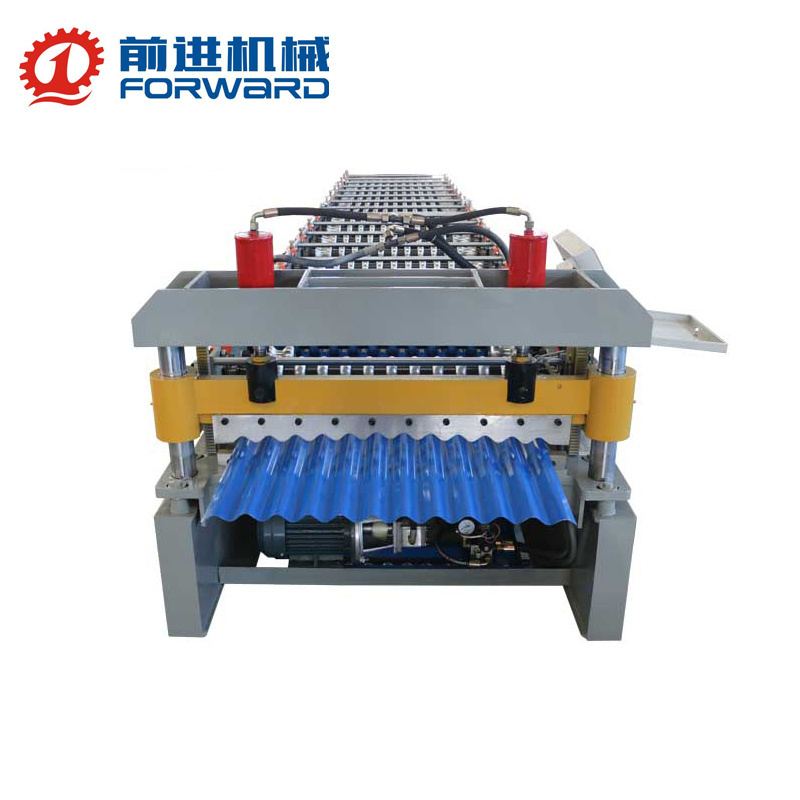

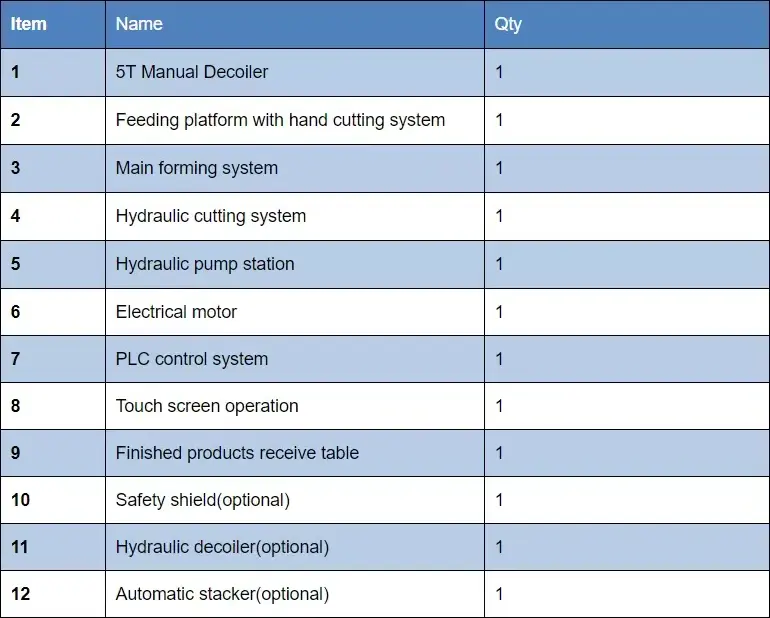

Corrugated roof tile roll forming machine

|

Roll forming machine

|

Frame Structure |

350H-beam welded and stand wall |

|

Sidewall |

16mm Carbon Steel Plate |

|

|

Screw/Bar |

8.8 grade / 25mm Galvanized |

|

|

Roller Station |

Roll forming 16 Steps |

|

|

Roller Shaft |

70mm 45# Steel Solid,Precision |

|

|

Shaft Material |

40#Steel Solid,Precision |

|

|

Roller Info. |

Gr12 steel harden chromed plated |

|

|

Transmission |

Chain ,1 inch(Jindun,Hangzhou) |

|

|

Motor Power |

5.5KW Type(Lichao,shanghai) |

|

|

Reducer Type |

5# Type,Jiangsu |

|

|

Output Speed |

12-15m/min(with cutting) |

| Manual decoiler | corrugated roof tile roll forming machine | Manual Stacker |

|

This machine is special equipment for rolling metal/steel coils, processing with decoiling,continuously roll forming, automatic length/quantity to cut for customer’s request. Whole unit with PLC control,AC variable frequency speed regulation technology for automatic roof profiling production, that would be the ideal equipment for cold steel roll forming and steel structure.