- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

500

-

Voltage:

-

220/380/custom

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ECHO MACHINERY

-

Weight:

-

800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine type:

-

Rotary Pre-made Pouch Packing Machine

-

Machine material:

-

SS304/SS316

-

Bag material:

-

Premade laminated film bag

-

CNC:

-

YES

-

Factory:

-

YES

-

Payment item:

-

TT30 % down,70% balance before shipping

-

Installation:

-

7 days/engineer with trainning

-

Customization:

-

yes

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Paper

-

Filling Material:

-

Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

500

-

Voltage:

-

220/380/custom

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ECHO MACHINERY

-

Weight:

-

800 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine type:

-

Rotary Pre-made Pouch Packing Machine

-

Machine material:

-

SS304/SS316

-

Bag material:

-

Premade laminated film bag

-

CNC:

-

YES

-

Factory:

-

YES

-

Payment item:

-

TT30 % down,70% balance before shipping

-

Installation:

-

7 days/engineer with trainning

-

Customization:

-

yes

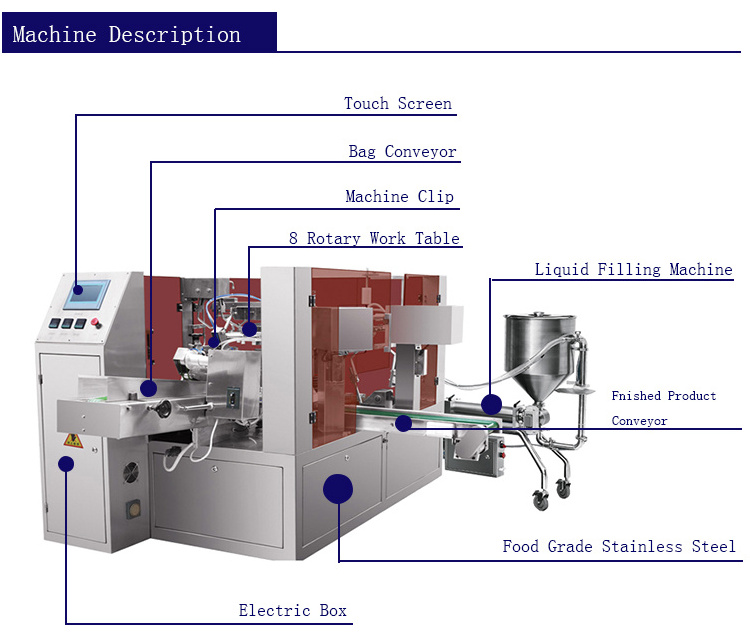

Main Features

1) Automatic rotary packing machine adopt precision indexing device and PLC to control each action and working station to make sure the machine operates easily and does accurately.

2) The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch..

3) Automatic checking system can check bag situation, filling and sealing situation.

The system shows 1.no bag feeding, no filling and no sealing. 2.no bag opening/opening error, no filling and no sealing 3.no filling, no sealing..

4) The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of products.

We can customize the suitable one for you according to your requiredment.

Just Tell us : Weight or Bag Size required.

- Liquid/paste type: detergent, rice wine, soy sauce, rice vinegar, fruit juice, beverage, tomato sauce, peanut butter, jam, chili sauce, bean paste,etc.

- Block material: bean curd cake, fish, eggs, candy, red jujube, cereal, chocolate, biscuit, peanut, etc.

- Granular type: crystal monosodium glutamate, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer,etc.

- Powder type: milk powder, glucose, monosodium glutamate, seasoning, washing powder, chemical materials, fine white sugar, pesticide, fertilizer, etc.

- Class of pickles, pickled cabbage, kimchi, pickled cabbage, radish, etc.

- Various bag types are available: All type of heat sealable performed side seal bags,block bottom bags,zip-lock recloseable bags,stand-up pouch with or without spout,paper bags etc.

| The Main Technical Parameters | |

| Model | MR8-200/300RW |

| Bag Size | Width:80-210/200-300mm, Length:100-300/100-350mm |

| Filling Volume | 5-2500g (Depending on type of products) |

| Capacity |

30-60bags/min (The speed depends on type of products and packaging material used)

25-45bags/min (For zipper bag) |

| Package Accuracy |

Error≤±1% |

| Total Power | 2.5KW (220V/380V,3PH,50HZ) |

| Demension | 1710*1505*1640 (L*W*H) |

| Weight | 1480KGS |

| Compress Air Requirement | ≥0.8m³/min supply by user |

|

We can customize the suitable one for you according to your requiredment. Just Tell us : Weight or Bag Size required. |

|

| Parts of Machine | ||||||||||

| Parts | PLC | Touch Screen | Frequency Conveter | Vacuum Pump | Printer | Main Motor | Temperature Controllor | Proximoty Swith |

Magnetic Value |

Cylinder |

| Brand | SIEMENS | SIEMENS | TOSHIBA | ORION | SHENG LONG | EVERGEAR | AISET | OMRON | FESTO | AIRTAC |

| Oringin | Germany | Germany | Japan | Japan | China | China | China | Japan | Germany | China |

| Can replace parts as needed | ||||||||||

| Work Process | |

| Safety Measures |

1.no bag feeding, no filling and no sealing. 2.no bag opening/open error, no filling and no sealing 3.no filling, no sealing |

|

Product Process |

Station 1 Bag Feeding

Station 2 Date Printing (option)and Open zipper bag Station 3 Open bag Station 4 Filling Materials Station 5,6,7 : Vibration,Air Removal,Nitrogen Filling,Close Zipper,Hole Punching,Heat Sealing Remark:No.5.6.7.Stations are based on customer requirements for adjusting. Station 8 Heat Sealing and Product Output |

|

Stations are based on customer requirements for adjusting. |

|

2.according to the special requirements of customers, personalized customized products;

3. Train technicians for customers free of charge;

4. Free professional technical engineers to plan the site on site and design the best process and plan.

6. Assist the client in drafting the construction plan;

ECHO have the trained team to follow your orders methodically to guarantee the products can be finished on time with high quality.

2. Parts Replacement , Don’t worry about the parts damaged or not sold after the machine is sold.we have a field factory with hundreds of enployees to serve you.

3. Engineer Asssignment , Lifelong maintentance,If your equipment breaks down,we will arrange engineers to repair it.

4. Online Instruction , We open online services,as long as your equipment failure,our engineers will be the first time for a one-to-one trou-bleshooting.

5. Feedback Survey, The engineer is required to bring a questionnaire to fill in the satisfaction with the engineer and the use of the equipment.