- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Nylon Monofilament Extruder

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

28000*2500*1970mm

-

Weight:

-

6000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Fishing Net:

-

Nylon monofilament extruder machine

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Nylon Monofilament Extruder

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

28000*2500*1970mm

-

Weight:

-

6000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Fishing Net:

-

Nylon monofilament extruder machine

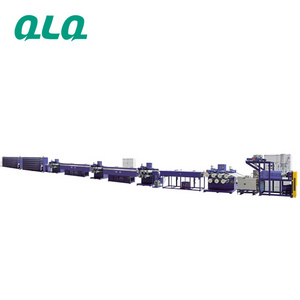

Nylon Monofilament Extruder Machine

1. Overview of Nylon monofilament extruder machine

We have full experience in monofilament machine supplying. According to about 20 years experiences in this field, we have many many monofilament machines are in good production in all over the world.

Our monofilament machine can use virgin resin or recycled flakes of PP, PET, Nylon as material to get very monofilament of good quality.

Monofilament can be used to make brush, broom, fishnet, zipper, string instrument.

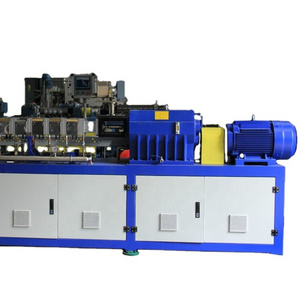

2. Configuration of Nylon monofilament extruder machine

|

No. |

Part Name |

Qty. |

Introduction of Main Parts |

|

1 |

Extruder |

1set |

1. Raw material : PET virgin or bottle flakes, Nylon 2. Frequency conversion control speed. 3. Hard tooth surface gear motor: Jiangsu changzhou. 4. Screw and cylinder: Made in Zhejiang Zhoushan. 5 . Material of screw heating: Al Casting. |

|

2 |

Spinning die |

1pc |

1. Heating method of die head: oil heating. 2. Material of spinneret: SUS316. 3. Frequency conversion control speed, cycloidal pinwheel reducer.

|

|

3 |

Cooling water tank |

1set |

1. Yarn separate pole is movable. 2. Material of box: stainless steel. |

|

4 |

Seven roller Stretching A |

1set |

1 . Frequency conversion control speed. Frequency conversion motor. 2. Steel structure of box, gear transmission, running balance. 3. In front, one rubber roller and stainless steel separate pole.

|

|

5 |

Hot water tank |

1set |

1. Material is stainless steel with heat preservation, and cover is opened by gas 2. Heating method :electrical heating 3.Equip water recycling pump |

|

6 |

Seven roller Stretching B |

1set |

1 . Frequency conversion control speed Frequency conversion motor 2 . Steel structure of box, gear transmission, running balance. 3. In front, one rubber roller and stainless steel separate pole

|

|

7 |

Hot blast stretching recycled oven |

1set |

1 . Single layer recycled hot blast oven 2. Equip wind power control 3. Hot blast path especial design make them equality 4. Frequency control of motor speed |

|

8 |

Seven roller Stretching C |

1set |

1. Frequency conversion control speed Frequency conversion motor 2. Steel structure of box, gear transmission, running balance. 3. In front and back, each with one rubber roller and stainless steel separate pole.

|

|

9 |

Oiling unit |

1set |

1. Frequency conversion control speed Frequency conversion motor |

|

10 |

Yarn guider system |

1set |

|

|

11 |

Winder |

2sets |

Frame style winder |

|

12 |

Cabinet |

1set |

Shown in another list |

3. Pictures of Nylon monofilament extruder machine

• We design, engineer and manufacture and customized the extrusion line.

• Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

• Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

• Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.