- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

3500 KG

-

Power (kW):

-

48.5KW

-

Fitting:

-

4 cutting unit

-

Feeding:

-

al gantry robot loading and stacking

-

Max working length:

-

2500mm

-

Working width:

-

550-1100mm

-

Max working thickness:

-

65mm

-

Power for main saw:

-

7.5kW*4

-

Power for scoring saw:

-

1.5kW*4

-

Program:

-

Windows 7

-

Air pressure:

-

0.6Mpa

-

Installation size:

-

5100*2914*2100mm

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SAGAMAC

-

Machine Type:

-

Door cutting machine

-

Weight (KG):

-

3500 KG

-

Power (kW):

-

48.5KW

-

Fitting:

-

4 cutting unit

-

Feeding:

-

al gantry robot loading and stacking

-

Max working length:

-

2500mm

-

Working width:

-

550-1100mm

-

Max working thickness:

-

65mm

-

Power for main saw:

-

7.5kW*4

-

Power for scoring saw:

-

1.5kW*4

-

Program:

-

Windows 7

-

Air pressure:

-

0.6Mpa

-

Installation size:

-

5100*2914*2100mm

Product Description

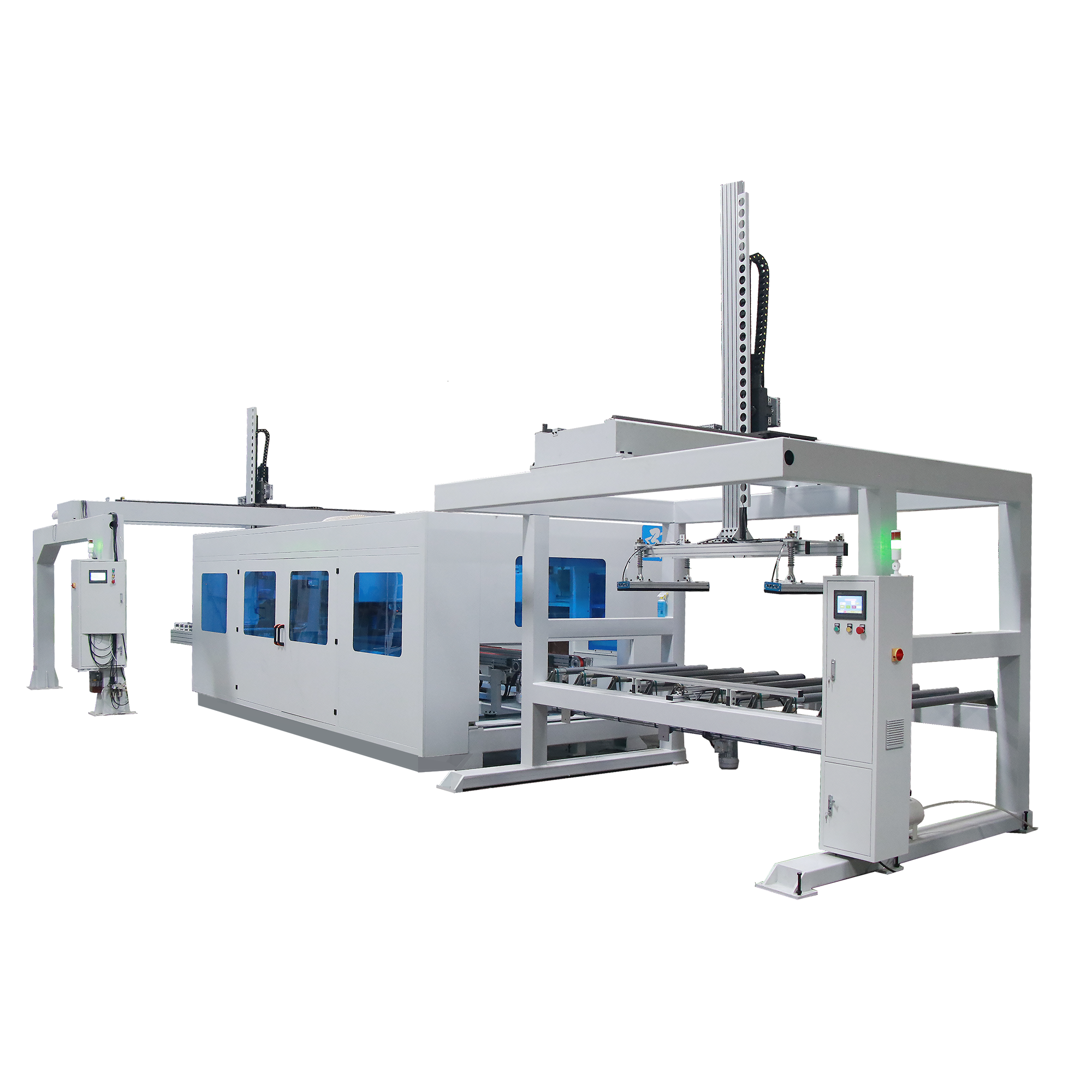

M4G2 Door 4 edge cutting center

Optional Robot gantry auto feeding and stacking

The idea way for industrial bulk production of door

M4G2 is heavy duty high precision industrial cutting center for door, both can work single machine or got ability to upgrade to meet the production line, pass through feeding, optional Robot gantry feeding or outlet system, greatly save manual work. 4 sets of cutting unit with design of scoring blade joint main cutting blade to effectively avoid edge breaking. Easy smart control with program quick to set all fully automatically, and automatic centering function plus soft material for door moving, makes process extremely precise and well protect the door surface. The whole covering design of machine makes it extremely safe for use, and central dust collection makes working condition clean.

Details Images

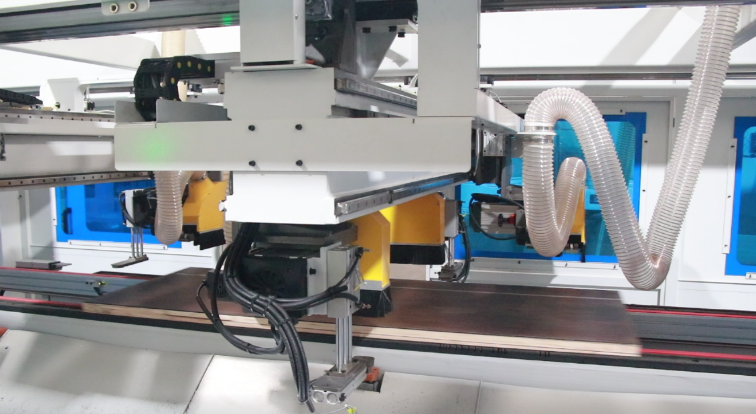

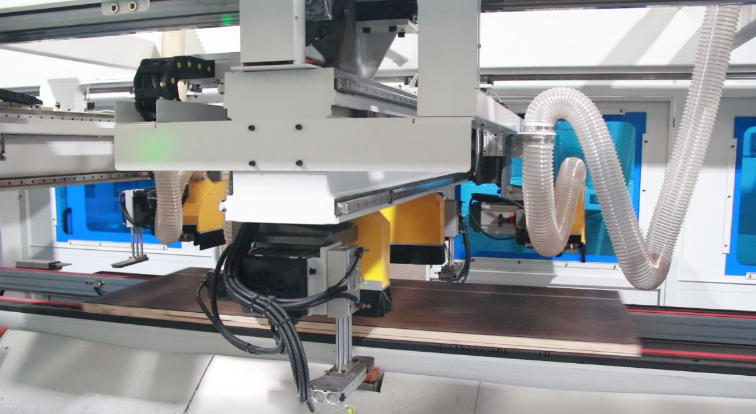

1 Conveyor system

Synchronized conveyor feeding belt send material to the mechanical stop, then belt lower down the auto centering system will push the door to right potion accounted by the center width and length, after position finish, there is quick vacuum system starts to fixed the door stable and ready for cutting, after cutting finish, vacuum stopped and belt raise to take door out.

2 Feeding Robot

Optional Gantry robot is used for automatic feeding and outlet stacking, the gantry robot got build in parallel conveyor roller with auto centering system to make sure it well match and smooth feeding to the main cutting machine.

3 Control Program

Professional cnc center system with modification to make setting of quick an easy.

4 HIGH LIGHTS OF M4G2

Automatic centering from 3 side, right and left fixed and then back pushing, to make sure the door is right at the center

4 pcs of cutting unit, 2 side cutting 1 time, makes it nearly double speed than traditional 3 cutting unit model, 1 minutes to cut

Scoring blade to prevent edge break

Vacuum table to stable hold the door

PU roller used for well protect the door when do centering push

Wast material conveyor take the wast material automatically out

Scanning function acceptable for integrate automation line.

High rigidity heavy duty structure makes it work for life long high precision

5 Parameter

|

Model

|

M4G2

|

|

Fitting

|

4 cutting unit

|

|

Feeding

|

Conveyor belt optional gantry robot loading and stacking

|

|

Max working length

|

2500mm

|

|

Working width

|

550-1100mm

|

|

Max working thickness

|

65mm

|

|

Power for main saw

|

7.5kW*4

|

|

Power for scoring saw

|

1.5kW*4

|

|

Program

|

Windows 7

|

|

Installation power

|

48.5kW

|

|

Air pressure

|

0.6Mpa

|

|

Dust collection

|

120mm

|

|

Installation size

|

5100*2914*2100mm

|

|

Weight

|

3310kgs

|

SAGA FULLY AUTOMATIC DOOR PRODUCTION SOLUTION.

SAGA‘s Brand"3".is a speciallized and professional factory for door production machine and its automatic plant like robot lifting gantry for loading and stacking, conveyor feeding or belt feeding system, all for help our cusotmer to build their advanced door factory and to be competitve both on quality and efficiency.

Hot Searches