- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

adjustable

-

Dimension(L*W*H):

-

adjustable

-

Product name:

-

Powder Coating System

-

Application:

-

car rims, bike frames, railings

-

Usage:

-

iron fencing & truck parts

-

Technology:

-

Electrostatic Powder Spraying Technology

-

Advantage:

-

Environmental-protection

-

Coating color:

-

Customers Demand

-

Function:

-

Metal Surface Powder Coating

-

Coating material:

-

Alumimum

-

Control System:

-

PLC+Touch Screen Automatic

-

Kinds of coating:

-

Automaitc Powder Coating

-

Weight:

-

Customized

-

Certification:

-

ISO9001

Quick Details

-

Machine Type:

-

Powder coating line

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ANTAI

-

Voltage:

-

380V

-

Power:

-

adjustable

-

Dimension(L*W*H):

-

adjustable

-

Product name:

-

Powder Coating System

-

Application:

-

car rims, bike frames, railings

-

Usage:

-

iron fencing & truck parts

-

Technology:

-

Electrostatic Powder Spraying Technology

-

Advantage:

-

Environmental-protection

-

Coating color:

-

Customers Demand

-

Function:

-

Metal Surface Powder Coating

-

Coating material:

-

Alumimum

-

Control System:

-

PLC+Touch Screen Automatic

-

Kinds of coating:

-

Automaitc Powder Coating

-

Weight:

-

Customized

-

Certification:

-

ISO9001

Products Description

Simple description

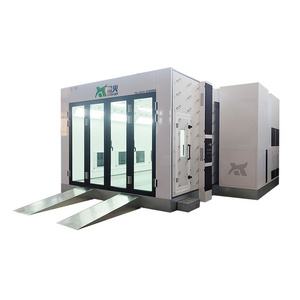

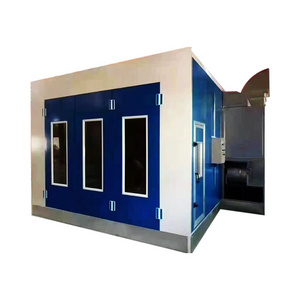

The complete equipment of the dry spray paint room is composed of the main operation room, the air supply and exhaust system, the air supply and exhaust piping system, the exhaust gas treatment system of the heating system, the fire fighting system, the electronic control system and the lifting operation platform.

Features

* Efficien

* High performance

* Easy to install

* High performance

* Easy to install

1. Pre treatment coating series: physical various treatment, including sand blasting and shot blasting; chemical passing through spraying type, tank immersion type, tank immersion spraying type.

2. Electrostatic powder coating series: all kinds of imported, domestic, manual, automatic powder spraying equipment, all kinds of material powder spraying chamber, pulse recovery, multi-tubed cyclone + filter core, cyclone + bag recovery device.

3. Immersion, painting and coating series: all kinds of imported, domestic, manual, automatic painting equipment,manual, cup type electrostatic painting equipment, dry type, water curtain type, water-rotating type, whirlwind vortex volume, telescopic, type, these kinds of painting booth, all sorts of circulating varnished slots.

4. Coating production line: drying, curing system, strong far infrared electric heating, energy-saving coal, coal gas (gas,LPG, natural gas), fuel oil, steam heating system.5. Electrophoresis coating production line: cathode, anode, beat, automatic electrophoresis production line, etc.

This design fully considers the following aspects:

2. Electrostatic powder coating series: all kinds of imported, domestic, manual, automatic powder spraying equipment, all kinds of material powder spraying chamber, pulse recovery, multi-tubed cyclone + filter core, cyclone + bag recovery device.

3. Immersion, painting and coating series: all kinds of imported, domestic, manual, automatic painting equipment,manual, cup type electrostatic painting equipment, dry type, water curtain type, water-rotating type, whirlwind vortex volume, telescopic, type, these kinds of painting booth, all sorts of circulating varnished slots.

4. Coating production line: drying, curing system, strong far infrared electric heating, energy-saving coal, coal gas (gas,LPG, natural gas), fuel oil, steam heating system.5. Electrophoresis coating production line: cathode, anode, beat, automatic electrophoresis production line, etc.

This design fully considers the following aspects:

1. Ensure coating quality. The whole line is designed to be free of dust and residue, reduce the quality problem factor, and

ensure the improvement of coating quality.

2. Ensure the advanced structure and reliable performance of the production line, and adopt the latest structure and latest patent technology under the economic and reasonable principle.

3. Give full consideration to energy-saving and cost-reducing technologies to reduce production and operation costs and

maintenance costs.

4. Give full consideration to organic combination of advanced technology and reasonable investment.

The design features and new technologies of this production line are described as follows:

1. Automatic powder spraying, which is convenient and flexible and greatly improves production efficiency.

2. Pulse filter cartridges recovery system to make full use of powder, which greatly improves the utilization rate of powder.

3. The inner wall of the solidified oven is smooth, flat and free of dust. It is a straight-through structure. The inlet and

outlet ends are provided with an air curtain device to reduce heat leakage.

4. Natural gas heating is adopted in the baking path, which is energy saving and environmental protection.

ensure the improvement of coating quality.

2. Ensure the advanced structure and reliable performance of the production line, and adopt the latest structure and latest patent technology under the economic and reasonable principle.

3. Give full consideration to energy-saving and cost-reducing technologies to reduce production and operation costs and

maintenance costs.

4. Give full consideration to organic combination of advanced technology and reasonable investment.

The design features and new technologies of this production line are described as follows:

1. Automatic powder spraying, which is convenient and flexible and greatly improves production efficiency.

2. Pulse filter cartridges recovery system to make full use of powder, which greatly improves the utilization rate of powder.

3. The inner wall of the solidified oven is smooth, flat and free of dust. It is a straight-through structure. The inlet and

outlet ends are provided with an air curtain device to reduce heat leakage.

4. Natural gas heating is adopted in the baking path, which is energy saving and environmental protection.

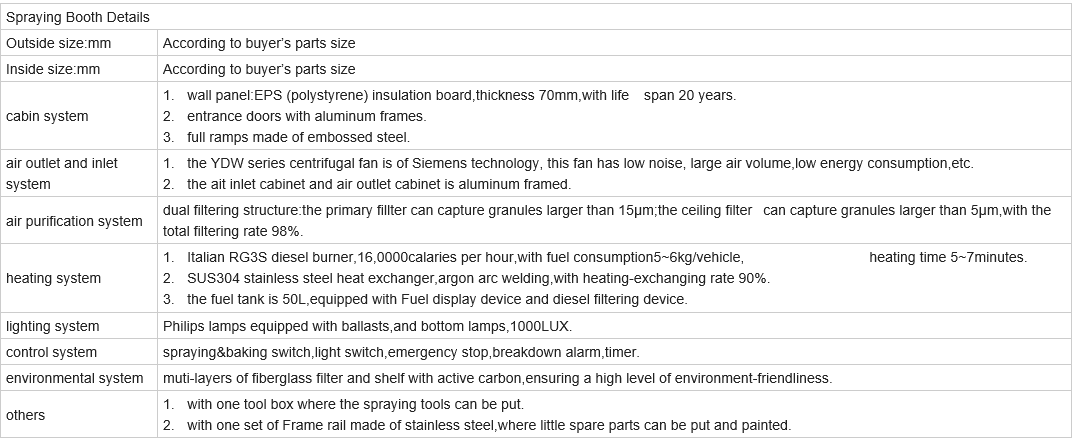

Technical Parameters

Details Images

Certifications

Hot Searches