- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

Offset Printing Machine

-

Weight (KG):

-

20

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JCTPRINT

-

Product name:

-

PU lamination polyurethane rubber roller coated plastic roller

-

Diameter:

-

10mm-670mm

-

Hardness:

-

20A-100D

-

Tempertature:

-

300degree

-

Length:

-

50mm-8200mm

-

MOQ:

-

1pcs

-

Application:

-

All kinds of printing machine

-

Shipping method:

-

DHL Fedex TNT UPS

-

Place of origin:

-

China

-

Payment:

-

T/T and so on

Quick Details

-

Condition:

-

New

-

Type:

-

Roller

-

Use:

-

All brand printing machine

-

Printing Type:

-

Offset Printing Machine

-

Weight (KG):

-

20

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JCTPRINT

-

Product name:

-

PU lamination polyurethane rubber roller coated plastic roller

-

Diameter:

-

10mm-670mm

-

Hardness:

-

20A-100D

-

Tempertature:

-

300degree

-

Length:

-

50mm-8200mm

-

MOQ:

-

1pcs

-

Application:

-

All kinds of printing machine

-

Shipping method:

-

DHL Fedex TNT UPS

-

Place of origin:

-

China

-

Payment:

-

T/T and so on

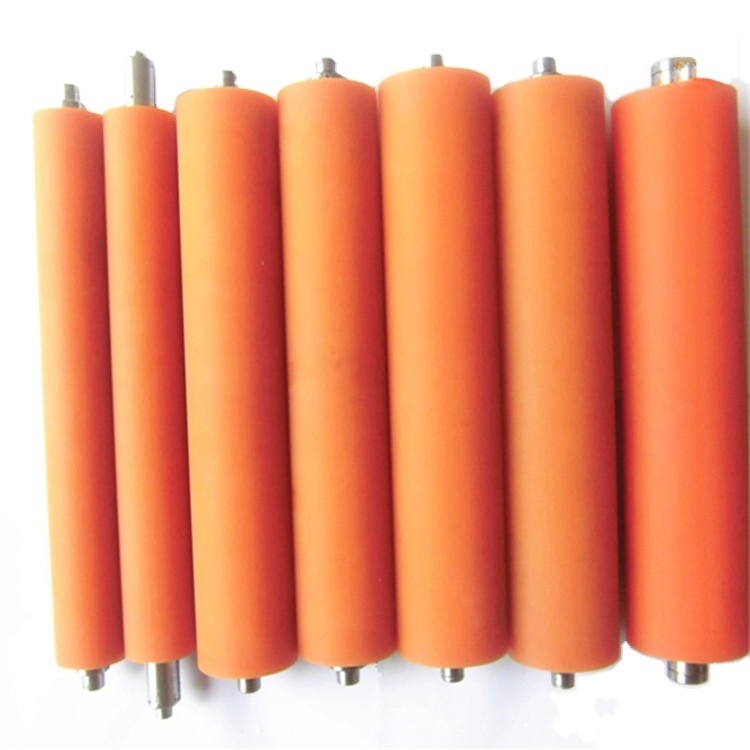

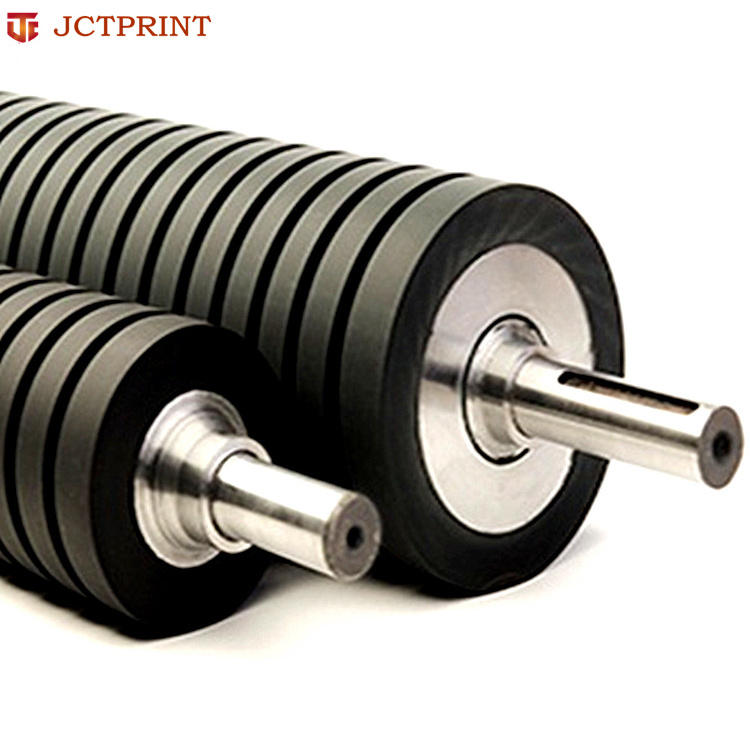

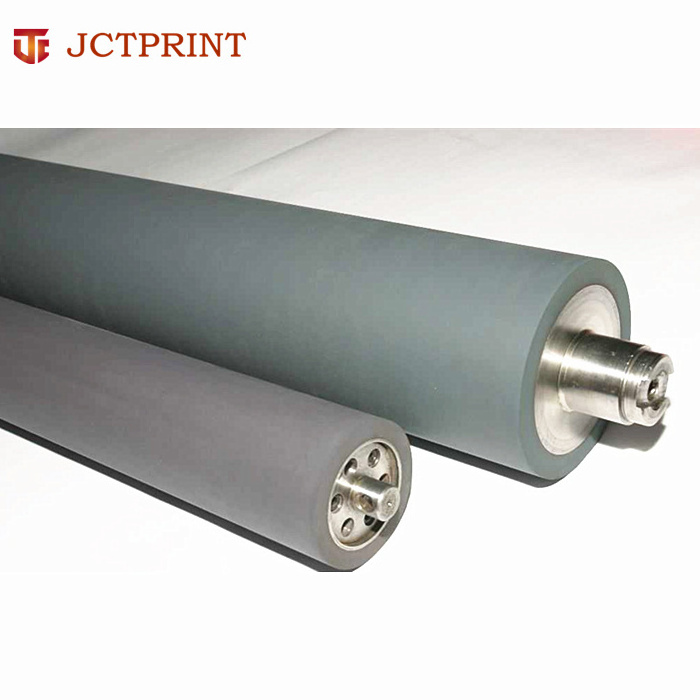

UV printing roller NBR rubber roller for flexo printing machine

1. Specification of rubber rollers

| size |

According To Customer's Drawing

(For offset printing roller,please tell us the model and we can check if we have the drawing ) |

| Dimension | 10MM-1500MM,Length:50MM-8200MM |

| Material | NBR,Silicone,Rubber,Polyurethane,EPDM, hypalon ETC |

| Hardness | 18A-100 |

| Tolerance | 0.05mm |

| Temperature | According customers's requirements |

| Color | Red, Black, White, Clear, etc can do the color base on your pantone NO. |

| Roll core | stainless steel,45#steel or 20#steel or 5#aluminum seamless pipe |

2. Rubber roller application in all industries

| Industry | Name |

| Rubber roller for textile industry |

Glue roller

Dispensing roller Skew roller Silk roller Dyeing roller squeezing roller |

| Rubber roller for plastic industry |

Winding roller

Paint roller Extrusion roller Tension roller |

| Rubber roller for Steel industry and metallurgy industry |

Pickling roller

Laminating roller Cleaning roller Reversing roller Extrusion roller Conveying roller |

| Rubber roller for Paper making industry |

Stone roller

Corner roller Winding roller Paint roller Extrusion roller Tension roller |

| Rubber roller for Printing and dyeing |

Ink ductor roller

Intermediate roller Transfer roller Ink form roller Ink vibrator roller Water ductor roller squeezing roller spreading roller |

A.Raw materials :

1) Base roller

We are using #45 steel , #201stainless steel #304stainless steel and 5# aluminum seamless pipe as the base roller.And we are adopting a reasonable thickness base roller according to customer’s drawing. Some manufacturers will reduce the thickness of the steel pipe in order to get the price advantage.Such roller can’t meet the standards.But we won’t do that.

2

)

Rubber

Our rubber are all imported from Germany or the US and then we mix them in our factory.The rubber coating technical we are using is winding technical. we casting the rubber on the base roller layer by layer and then vulcanize it to make the green rubber into mature rubber.

While other manufacturers are using sheet coating technical,and the rubber is cold in processing and will cause adhesion problems easily.

B. Production process

1) Hot charging technicals

Adopt hot charging technicals to install the shaft head, and then weld after contraction to ensure the quality of shaft installation.While other supplier are welding the shaft head directly.

2 ) Dynamic balancing

We will do 3 times of dynamic balancing test in the process of production of each rubber roller,which will ensure the using effect. In general,If it can displayed within 10g on the dynamic balancing device, it is called dynamic balancing. But we can do less than 2g.

3) Testing by making small sample before mass production

We will make a small sample before the official production, after vulcanization, 24 hours later we will check the hardness, color, and Impurity situation. We will control the hardness tolerance within 3degree. If it is not qualified we will change the formulated immediately and to make the sample again till all the data reach the customer’s request.

C. Quality control Department

Using all-imported laser tester to ensure that the geometric size and the accuracy of the roller can reach 0.01 mm