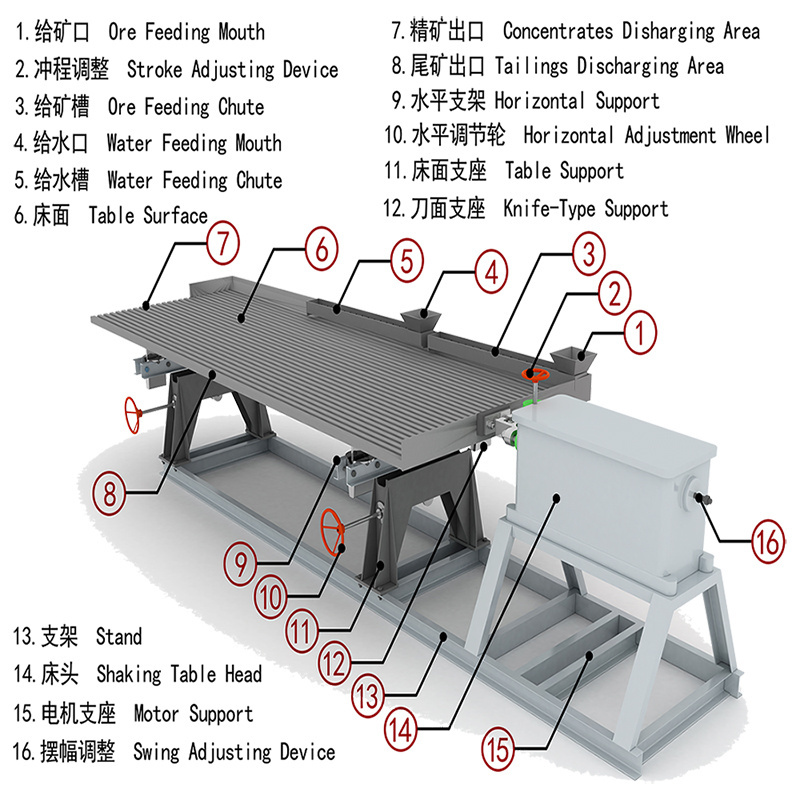

The working principle of shaking table is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove), to allow loose layering of ores on the bed surface and fan-shaped zoning.

Different densities and grains have different lateral and vertical effects on the bed surface and different moving directions, but they are fan-shaped on the bed surface, which can produce a variety of products of different quality.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Clients Local Standard

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

800 KG

-

Certification:

-

ISO9001 CE BV

-

Capacity:

-

0.5-2.5 Tons/hour

-

Feeding density:

-

10-30%

-

Stroke:

-

16-22mm

-

Feeding size:

-

0.074-2mm

-

Transverse slope of deck:

-

1-4 degree

-

Color:

-

Custumized

-

Application:

-

Mining Separation

-

Quality:

-

100% Tested

-

Advantage:

-

High Recovery Rate

Quick Details

-

Production Capacity:

-

99%

-

Place of Origin:

-

Jiangxi

-

Brand Name:

-

Changyi

-

Voltage:

-

Clients Local Standard

-

Dimension(L*W*H):

-

Varies

-

Weight:

-

800 KG

-

Certification:

-

ISO9001 CE BV

-

Capacity:

-

0.5-2.5 Tons/hour

-

Feeding density:

-

10-30%

-

Stroke:

-

16-22mm

-

Feeding size:

-

0.074-2mm

-

Transverse slope of deck:

-

1-4 degree

-

Color:

-

Custumized

-

Application:

-

Mining Separation

-

Quality:

-

100% Tested

-

Advantage:

-

High Recovery Rate

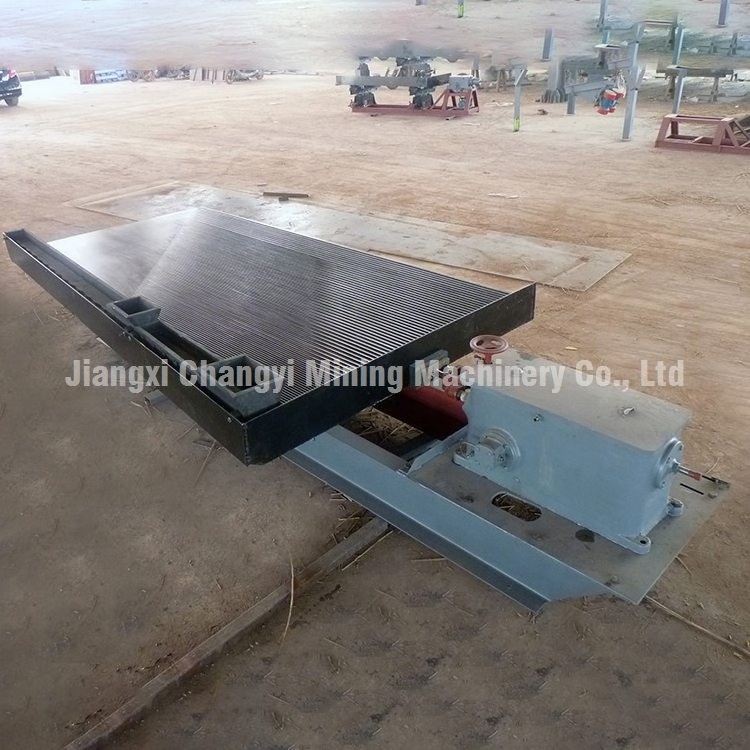

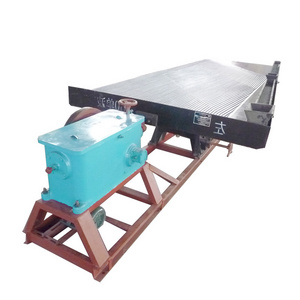

Product Description

Shaking table is a widely used equipment for gravity separation. Shaking bed beneficiation uses the function of mechanical shaking and water flushing to separate mineral particles according to density. It is a process of separating mineral particles according to density on a wide inclined bed surface by means of mechanical asymmetric reciprocating motion and thin inclined surface water flushing. It is one of the most widely used gravity separation methods for separating fine materials.

Features of Shaking Table

1. High enrichment ration high classification efficiency easy to safeguard and adjust stroke;

2. Strong wear-resistant of working surface;

3. Anti chemical etching acid and alkali resistant;

4. Adaptable to harsh environment;

5. Tight structure as springs are set inside.

Working Principle

Technical Parameters

|

Model

|

6-S 7.6

|

|

|

||

|

Deck type

|

Coarse sand

|

Fine sand

|

Slurry

|

||

|

Deck area(㎡)

|

7.6

|

7.6

|

7.6

|

||

|

Max feeding size(mm)

|

2

|

0.5

|

0.074

|

||

Note: Data only for reference, according to customer requirements for design and production.

Hot Searches