- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

WADJAY

-

Voltage:

-

380V / Customized

-

Weight:

-

4500 kg

-

Marketing Type:

-

Hot Product 2021

-

Product name:

-

Roof Sheet Forming Machine

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45# Steel Plated

-

Control system:

-

PLC

-

Cutting type:

-

Hydraulic Cutting

-

Frame:

-

H beam or U channel

-

Cutting blade material:

-

Cr12 Quenched

Quick Details

-

Type:

-

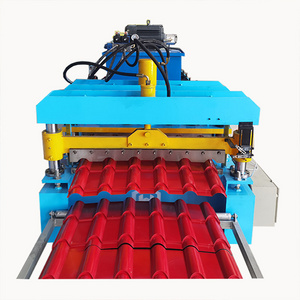

Tile Forming Machine

-

Tile Type:

-

Colored Glaze Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

WADJAY

-

Voltage:

-

380V / Customized

-

Weight:

-

4500 kg

-

Marketing Type:

-

Hot Product 2021

-

Product name:

-

Roof Sheet Forming Machine

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

45# Steel Plated

-

Control system:

-

PLC

-

Cutting type:

-

Hydraulic Cutting

-

Frame:

-

H beam or U channel

-

Cutting blade material:

-

Cr12 Quenched

Product Description

WADJAY

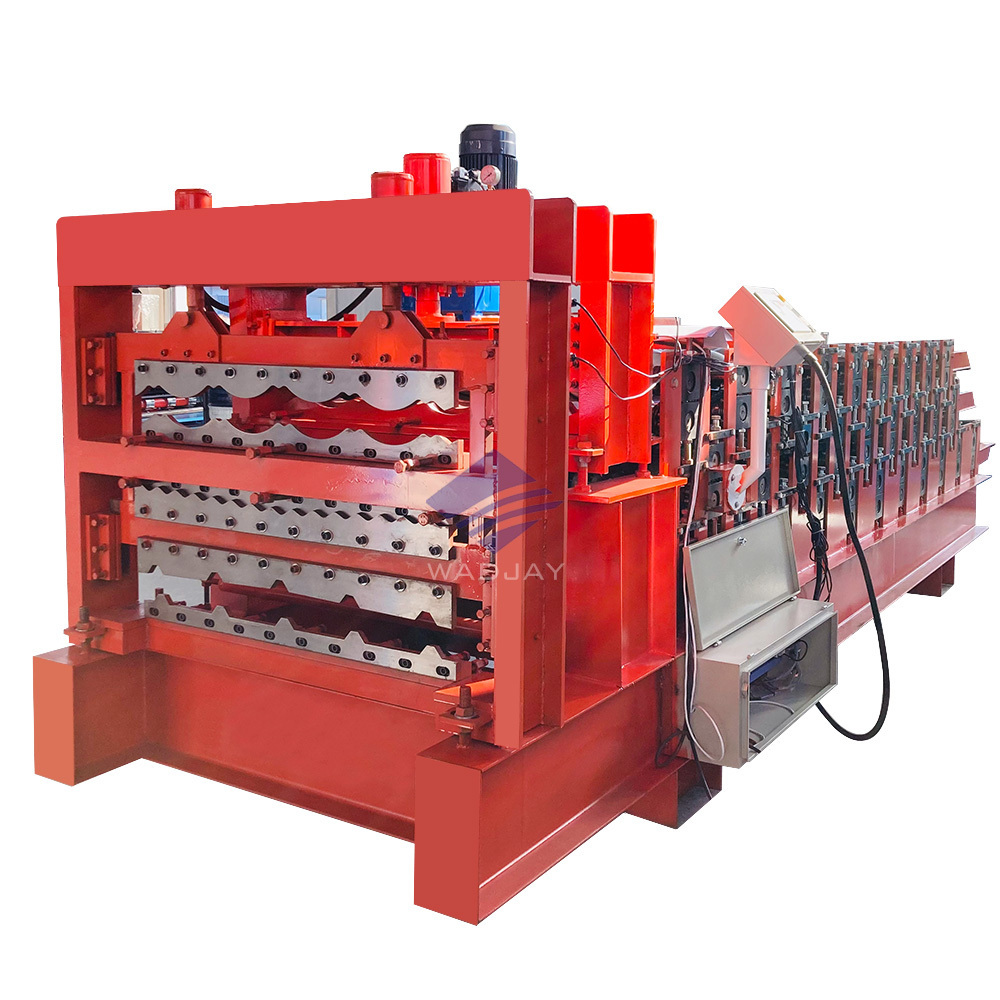

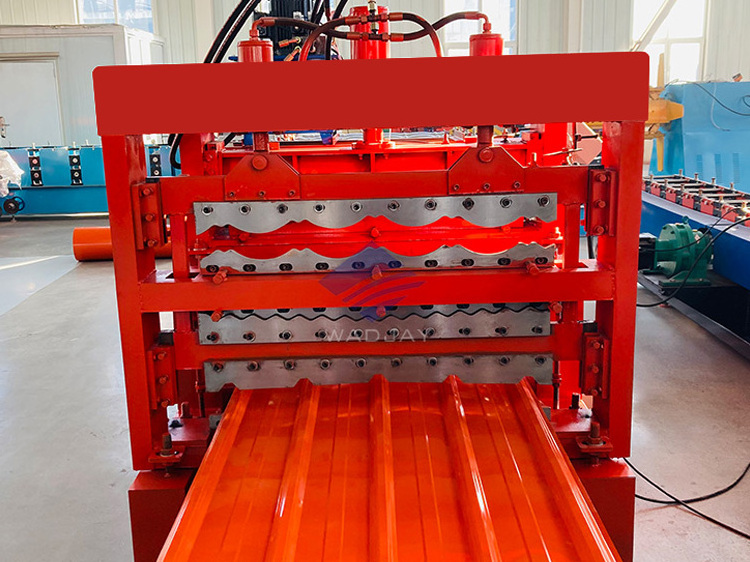

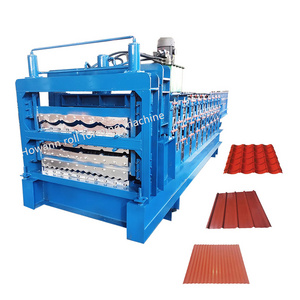

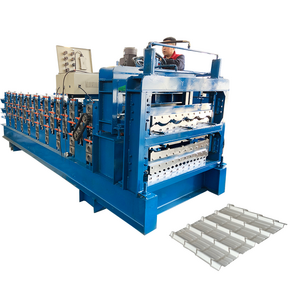

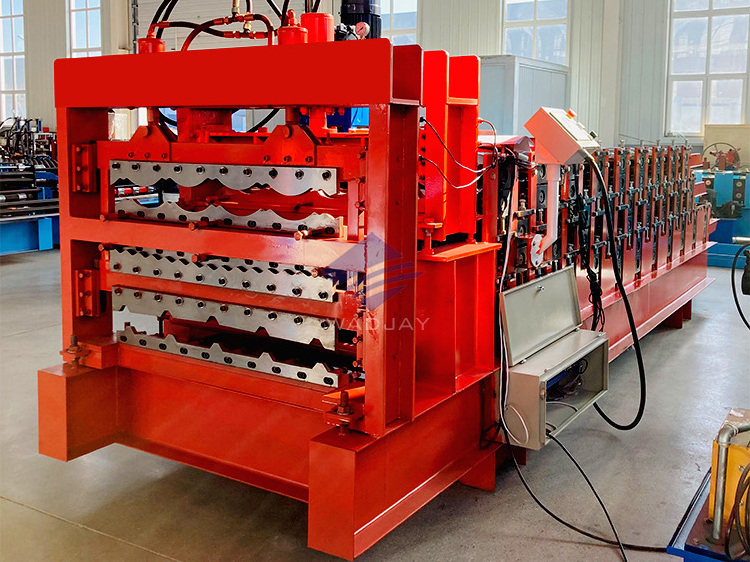

Ibr Panel Corrugated Metal Tile Roof Making Machine Three Layer Iron Sheet Roll Forming Machine

It is our company most popular products in building materials machine. For roof sheet, it include many type according to its different shape, popular type include corrugated tile roll forming machine, trapezoidal tile roll forming machine,glazed tile roll forming machine, ridge cap roll forming machine and other type profile panel roll forming machine.

1000MM

FEEDING WIDTH

★ This roll forming machine can form smooth and beautiful metal roofing sheet without any scratch on surface.

★

Roll forming process: uncoiler, roll forming, forming step effect, cut to length.

★

Fully automatic control system with PLC.

★

Easy operation: Set length and quantity on the control panel,machine will auto working.

★

Customized your own roll forming machine, We can design the machine according to your specification and profile drawing.

Specification

|

* Thickness of material : 0.3 mm ~ 0.8 mm

* Forming speed: 15~25 m/min.

* Hydraulic driving and cutting system. * Hard chrome coated rollers. |

Details Image

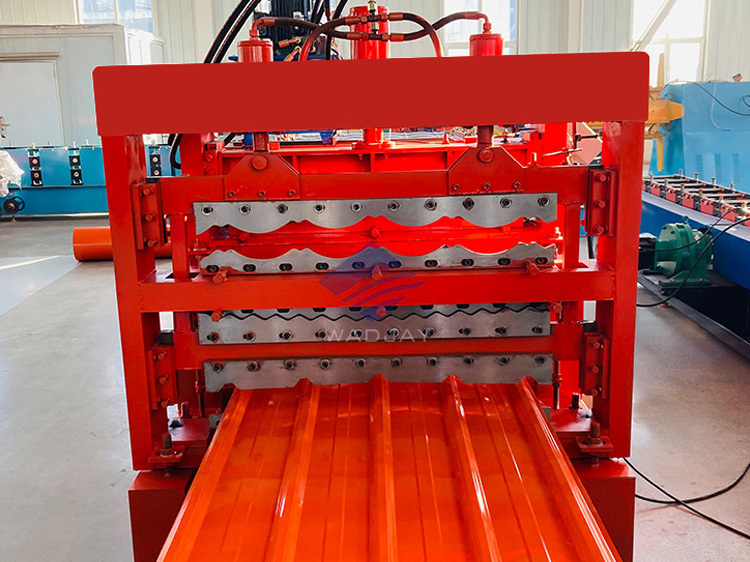

Decoiler

:

This component holds the raw material coil and feeds it into the roll forming machine.

Roll Forming Stations

:

Multiple sets of rollers gradually shape the material into the products profile.

Cutting System:

The machine may include a cutting mechanism to trim the purlins to the desired length.

Control System:

Modern machines often have computerized control systems to precisely control the production process

Hot Searches