- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Taishan

-

Dimension(L*W*H):

-

Depending on the boiler capacity

-

Weight:

-

Depending on the boiler capacity

-

Steam capacity:

-

Max. 400 t/h

-

Steam temperature:

-

170-500 ℃

-

Working pressure:

-

Max. 98 bar

-

Thermal efficiency:

-

85%-90%

-

Combustion method:

-

The Mixture

-

Grate type:

-

Step grate, chain grate, fixed grate, etc.

-

Fuel Type:

-

Biomass(woodchips, palm fiber, bagasse, etc.)

-

Application:

-

For power plant or industrial production

-

Fuel consumption:

-

Depending on the boiler capacity

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam, Indonesia, Pakistan, Thailand, Malaysia, Bangladesh

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ASME, CE, DOSH, ISO, GB

-

Marketing Type:

-

Hot product 2021

Quick Details

-

Core Components:

-

PLC, pressure parts

-

Steam Production:

-

Max 400 t/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Taishan

-

Dimension(L*W*H):

-

Depending on the boiler capacity

-

Weight:

-

Depending on the boiler capacity

-

Steam capacity:

-

Max. 400 t/h

-

Steam temperature:

-

170-500 ℃

-

Working pressure:

-

Max. 98 bar

-

Thermal efficiency:

-

85%-90%

-

Combustion method:

-

The Mixture

-

Grate type:

-

Step grate, chain grate, fixed grate, etc.

-

Fuel Type:

-

Biomass(woodchips, palm fiber, bagasse, etc.)

-

Application:

-

For power plant or industrial production

-

Fuel consumption:

-

Depending on the boiler capacity

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Viet Nam, Indonesia, Pakistan, Thailand, Malaysia, Bangladesh

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

ASME, CE, DOSH, ISO, GB

-

Marketing Type:

-

Hot product 2021

Product Description

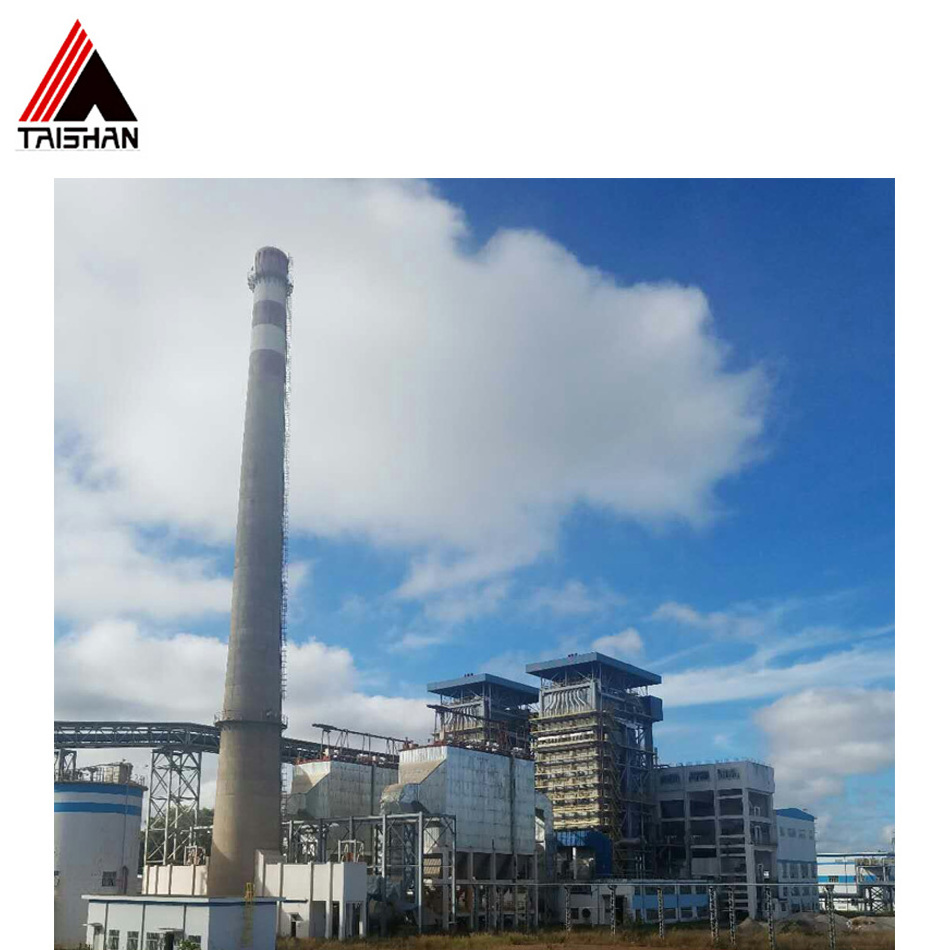

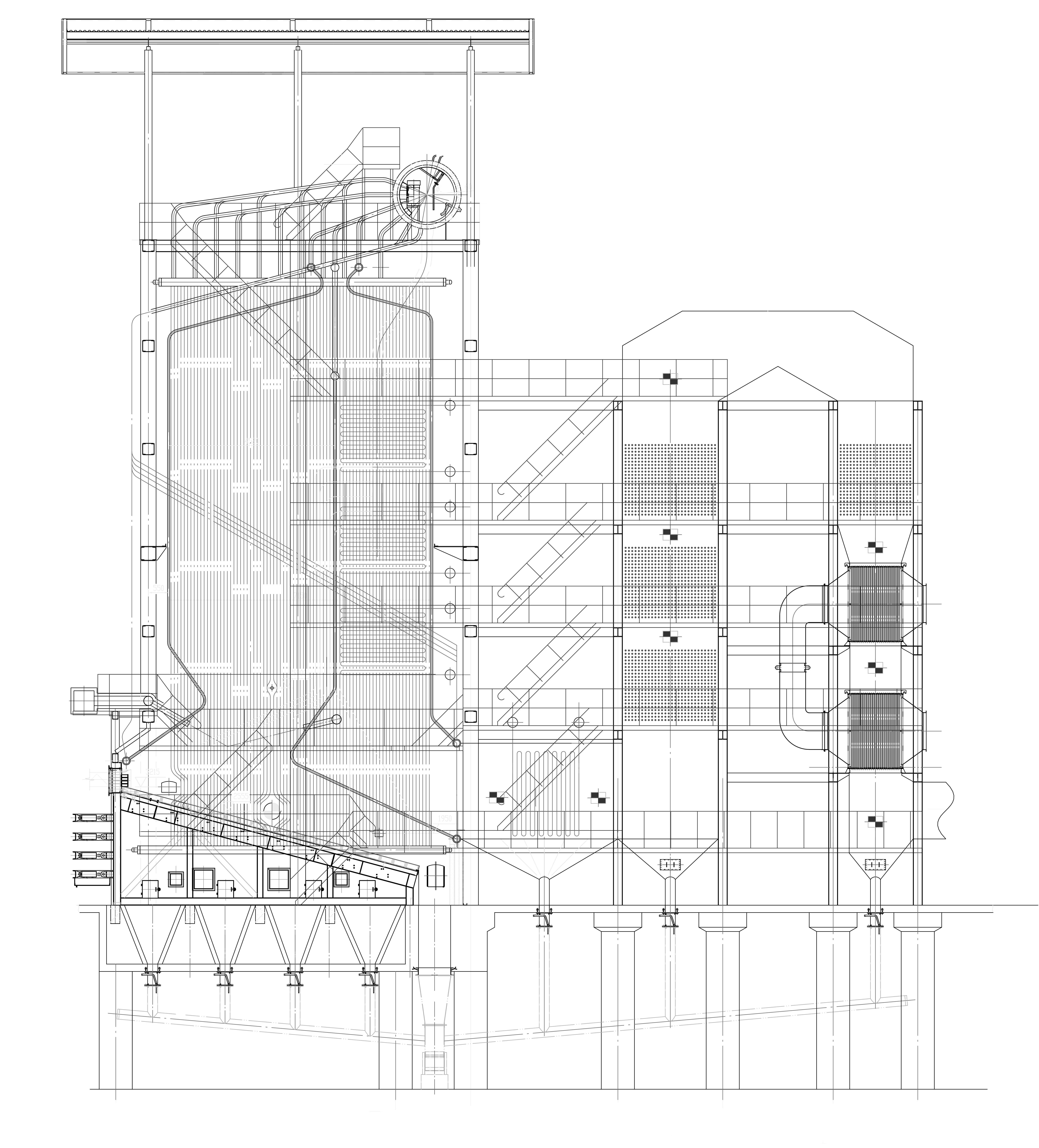

DHW series biomass boiler is single drum horizontal inclined reciprocating grate boiler, the reciprocating grate’s angle of inclination is 15°. The furnace is membrane wall structure, furnace outlet has slag-cooling tubes, and furnace outlet flue gas temp is lowered to below 800℃, lower than the melting point of fly ash, to prevent the fly ash from slagging on the superheater.

After the slag-cooling tubes, there are high-temperature superheater, low-temperature superheater, economizer and air preheater, there is spray type desuperheater between two superheaters. The flue gas temperature after air preheater is 160℃.

DHW series biomass boiler can generate low pressure steam with rated evaporation capacity of 10-400 ton/h and rated pressure of 1.25-9.8 MPa. The designed thermal efficiency is up to 90%.

After the slag-cooling tubes, there are high-temperature superheater, low-temperature superheater, economizer and air preheater, there is spray type desuperheater between two superheaters. The flue gas temperature after air preheater is 160℃.

DHW series biomass boiler can generate low pressure steam with rated evaporation capacity of 10-400 ton/h and rated pressure of 1.25-9.8 MPa. The designed thermal efficiency is up to 90%.

Features

1. Since biomass fuel is apt to slagging, reciprocating grate’s ceaseless movement avoids slagging.

2. Biomass fuel features small density and small ash particle, which is apt to flow with the flue gas, so we design high furnace and small flow velocity.

3. Secondary air ensures that the fuel’s standing time in the furnace makes the fuel burn out in the furnace.

4. The arch is used to strengthen the mixture of airflow in the furnace and organize the thermal radiation and hot flue gas flow in the furnace.

5. To avoid soot formation, the pitch of convection heating surface shall be in-line arrangement.

6. The convection bank has acoustic wave soot blower, which may remove the soot, and cleaning door is equipped.

2. Biomass fuel features small density and small ash particle, which is apt to flow with the flue gas, so we design high furnace and small flow velocity.

3. Secondary air ensures that the fuel’s standing time in the furnace makes the fuel burn out in the furnace.

4. The arch is used to strengthen the mixture of airflow in the furnace and organize the thermal radiation and hot flue gas flow in the furnace.

5. To avoid soot formation, the pitch of convection heating surface shall be in-line arrangement.

6. The convection bank has acoustic wave soot blower, which may remove the soot, and cleaning door is equipped.

Application

WNS series gas/oil fired steam boiler is widely used in chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry, construction industry.

WNS Gas/Oil Boiler

$34,500.00 - $155,800.00 / Set

Suitable fuel: LPG, LNG, diesel, heavy oil, biogas, etc.

Coal-fired steam boiler

$54,000.00 - $268,800.00 / Set

Suitable fuel: coal, biomass( woodchips, corn stalk, rice husk, palm fiber, etc.

CFB boiler

$82,000.00 - $1986,800.00 / Set

Suitable fuel: pulverized coal, s

olid pellet fuel

Hot Searches