- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

100%

-

Power:

-

11500

-

Dimension(L*W*H):

-

3250*2750*1900mm

-

Product name:

-

Aluminum Extrusions Cutting Machine

-

Control system:

-

PLC+touch screen

-

Material feed method:

-

servo+ball screw

-

Blade feed mode:

-

Hydraulic(servo high precision feed is optional)

-

Clamping method:

-

pneumatic horizonta clamp+vertical clamp.(hydraulic clamp is optional)

-

Cooling method:

-

Micro oil mist cooling

-

Machine type:

-

Aluminum Profile Cut Machine

-

Blade rotation speed:

-

1500-3500 rpm

-

After-sales Service Provided:

-

Online Support, Video Technical Support

-

Cutting material:

-

various aluminium profile, copper and non-metallic materials

Quick Details

-

Brand Name:

-

Chine Chern

-

Voltage:

-

3 phase, 380V or customized

-

Weight:

-

2600 kg

-

Production Capacity:

-

100%

-

Power:

-

11500

-

Dimension(L*W*H):

-

3250*2750*1900mm

-

Product name:

-

Aluminum Extrusions Cutting Machine

-

Control system:

-

PLC+touch screen

-

Material feed method:

-

servo+ball screw

-

Blade feed mode:

-

Hydraulic(servo high precision feed is optional)

-

Clamping method:

-

pneumatic horizonta clamp+vertical clamp.(hydraulic clamp is optional)

-

Cooling method:

-

Micro oil mist cooling

-

Machine type:

-

Aluminum Profile Cut Machine

-

Blade rotation speed:

-

1500-3500 rpm

-

After-sales Service Provided:

-

Online Support, Video Technical Support

-

Cutting material:

-

various aluminium profile, copper and non-metallic materials

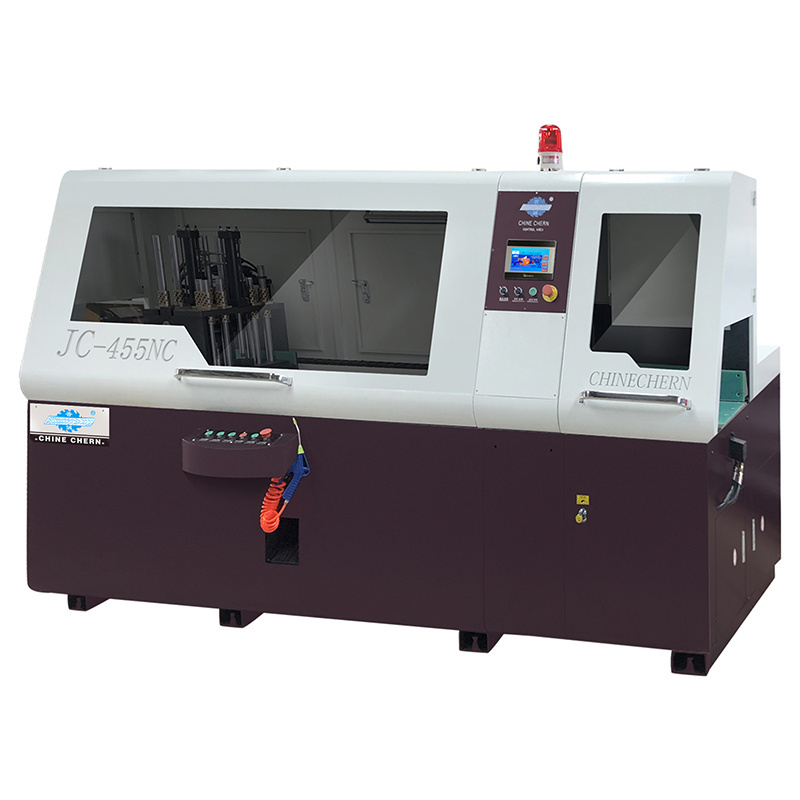

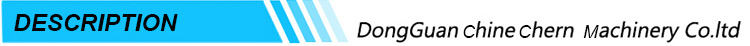

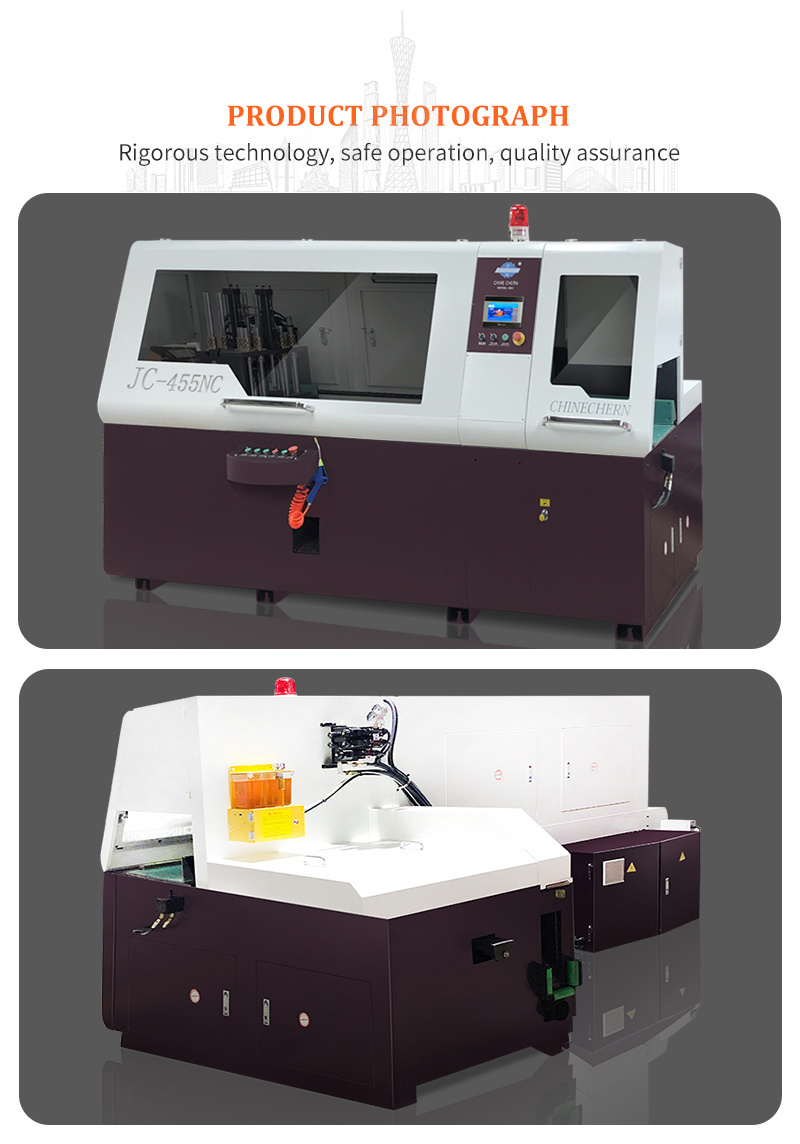

High Efficiency CNC Automatic Servo Feed Aluminum Extrusions Cutting Machine Aluminum Profile Cut Machine

The characteristics of High Efficiency CNC Automatic Servo Feed Aluminum Extrusions Cutting Machine Aluminum Profile Cut Machine:

The characteristics of High Efficiency CNC Automatic Servo Feed Aluminum Extrusions Cutting Machine Aluminum Profile Cut Machine:

1. Famous servo motor-driven in feed, PLC unit control, make the feeding accurate and steady.

2. Imported hydraulic system, powerful cutting and durable saw blade

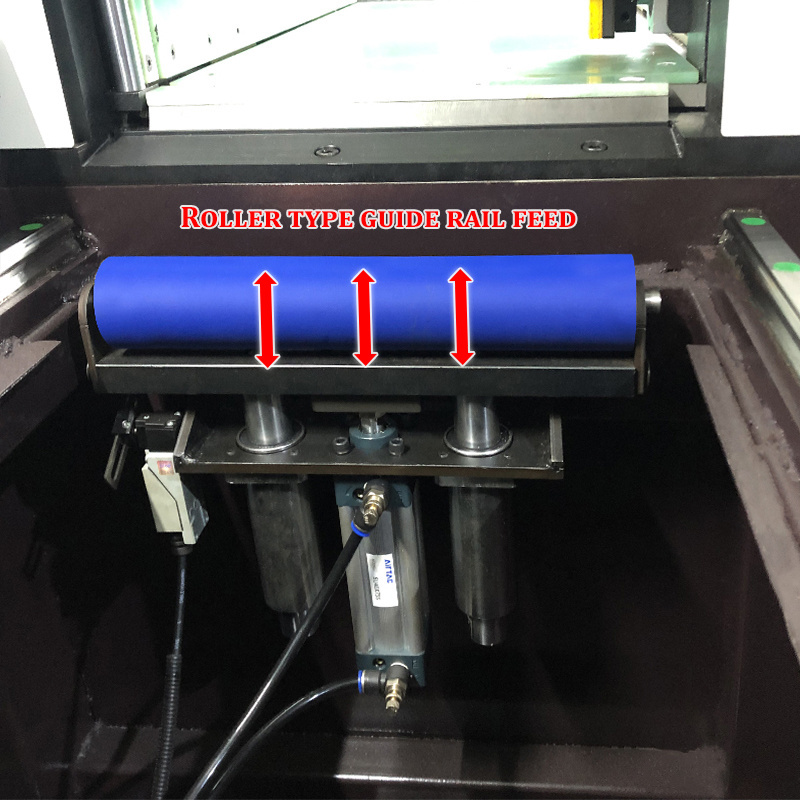

3. Linear guide rail with lube and horizontal slideway blade feed cutting make the cutting steady and accurate.

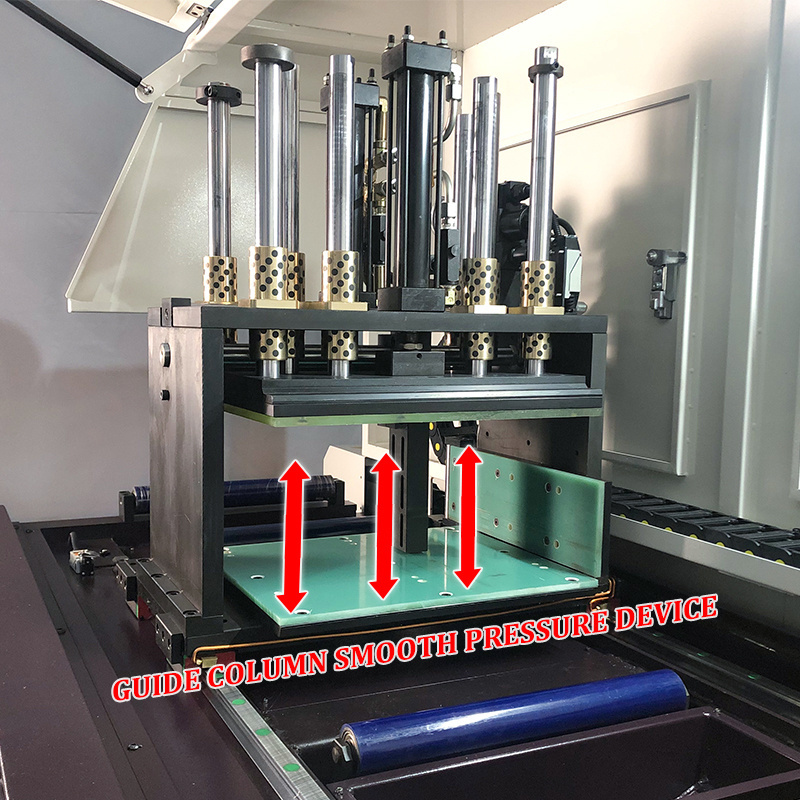

4. Separated control of cutting and clamping, special-designed clamping method make the clamping without any deformation.

5. Robust design ensures low vibration, low noise and long-time working.

6. Automatic micro oil mist cooling system makes the cutting surface smooth and of little flash and strain, also makes the saw blade long-time use.

7. The cutting scraps are treated together and the maintance is easy.

8. Easy to operate. Extremely powerful functions make it ideal for accurate cutting requirements.

9. Human/machine interface control provides user friendly operations.

10. Touch sensing screen. Numerically controlled, provides high cutting accuracy.

|

Aluminum Profile Cutting Machines |

|

|

Item |

specifications |

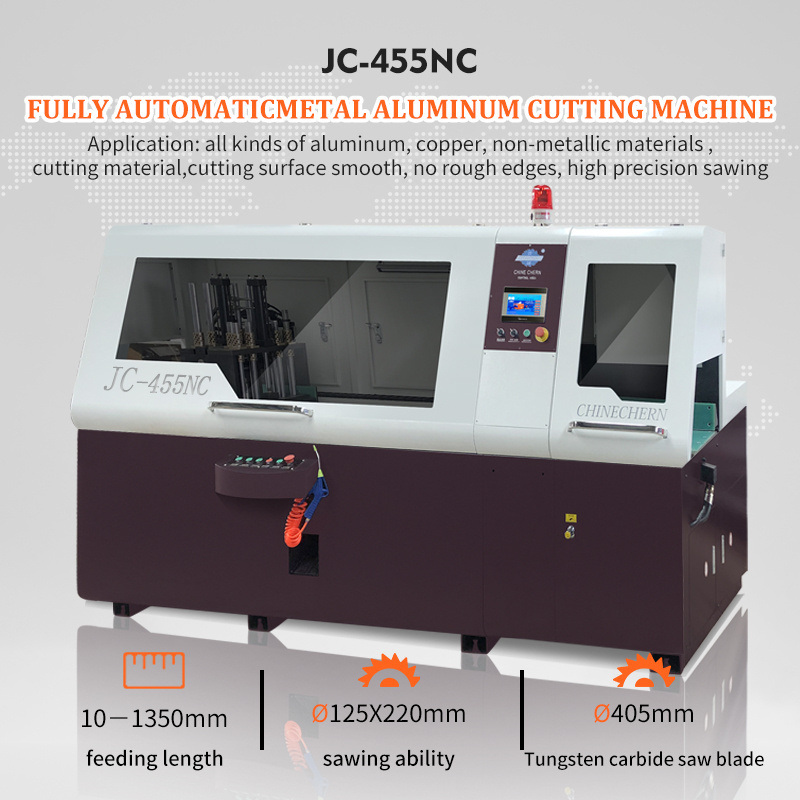

| Maximum cutting diameter | 100mm(125mm is optional) |

| Saw Blade diameter | 405mm(455mm is optional) |

| Saw blade rotation speed | 1500-3500 rpm |

| Saw base heading speed | 1.7m/min(9-37m/min is optional) |

| Saw base back speed | 67m/min |

| Spindle motor | 10hp inverter motor(15hp is optional) |

| Blade feeding oil pump motor | 3hp |

| Automatic material feeding system | 1.5kw AC servo(2kw is optional) |

| Automatic material feeding speed | 30m/min |

| Using air pressure | 5-6kgs/cm |

| Worktable height | 782mm or 845mm |

| Net weight | 2600kg |

| Dimension(L*W*H) | 3250*2750*1900MM |

| Touch screen | 7" |

| Max. loading weight of material feeding table | 200kg |

| Cutting capacity(H*W) | Φ125mm, 125*220mm, 60*300mm |

| Automatic material feeding stroke | 1350mm(2500mm is optional), repeatable feeding |

| Automatic material feeding accuracy |

±0.1mm~0.15mm |

| Material clamping method |

pneumatic (hydraulic is optional) |

| Saw blade feed method |

hydraulic(servo drive high precision feed is optional) |

* PLC: Japan Mitsubishi

* Servo motor: Japan Yaskawa

* Hydraulic system: Taiwan CML

* Main motor: Taiwan FUKUTA

* what is the material

* The material size

-

MAINTENANCE

The whole machine is guaranteed with one year warranty, life time maintenance and after-sales maintenance. Solutions shall be provided within 12 hours and on-site technical solutions shall be sent within 48 hours.

-

TECHNICAL TRAINING

On-site installation, commissioning and sample testing, one-to-one demonstration and guidance.

-

24/7 CUSTOMER SUPPORT

We provide exclusive solutions and timely technical support to help you improve production efficiency and solve your problems.

-

ENTERPRISE CORE

Leading company scale, industry qualification, brand strength guarantee; Introduce advanced technology and accessories from Taiwan and Japan to strongly guarantee product quality; Long-term service to well-known brand customers have a good industry reputation; Full coverage of pre-sales, in-sales, and after-sales, quick response to customer needs.

aluminium profile cut machine

Aluminum Extrusions Cutting Machine