The scrap metal briquetting machine uses hydraulic system to drive the hydraulic cylinder, the output of high pressure will be metal chips, powder and other metal raw materials cold pressed into cylindrical cake, molding at the same time to ensure that the original material remains unchanged. Convenient for storage and transportation, reduce the loss in the recycling process.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

HD-70

-

Power (kW):

-

4.5

-

Weight (KG):

-

600

-

Name:

-

Mini Scrap Metal Compactor

-

Application:

-

Scrap Metal Recycling

-

Raw material:

-

Aluminum / stainless steel / iron / copper / magnesium alloy

-

Dimensions:

-

1100mm*720mm*1050mm

-

Press Method:

-

Hydraulic Cylinder

-

Charging silo capacity:

-

50L

-

Cutting fluid recycling tank capacity:

-

18L

-

Mode of operation:

-

Full-automatic

-

Feeding mode:

-

Screw dosing (adjustable)

-

Cycle Time:

-

About 20 seconds

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhengzhou Haoding Machinery

-

Marketing Type:

-

New Product

-

Model Number:

-

HD-70

-

Power (kW):

-

4.5

-

Weight (KG):

-

600

-

Name:

-

Mini Scrap Metal Compactor

-

Application:

-

Scrap Metal Recycling

-

Raw material:

-

Aluminum / stainless steel / iron / copper / magnesium alloy

-

Dimensions:

-

1100mm*720mm*1050mm

-

Press Method:

-

Hydraulic Cylinder

-

Charging silo capacity:

-

50L

-

Cutting fluid recycling tank capacity:

-

18L

-

Mode of operation:

-

Full-automatic

-

Feeding mode:

-

Screw dosing (adjustable)

-

Cycle Time:

-

About 20 seconds

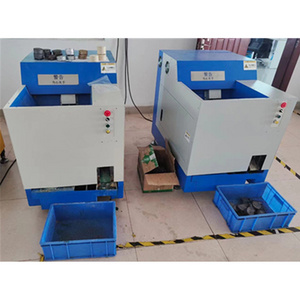

Products Description

Product Applications

Small automatic metal briquetting machine is suitable for compressing waste materials such as aluminum powder, aluminum chips, copper chips, saw iron chips, iron chips, cast iron chips, steel chips, iron ore powder and other non-ferrous metals.

The small metal chip briquetting machine can press copper, aluminum, iron, steel chips and other scrap materials generated from hardware processing into a single round cake with a diameter of 70 mm. It saves storage space and transportation costs. Cutting oil is automatically recovered during briquetting. The recovery rate is more than 95%. suitable for aluminum alloy profile factory, steel casting plant, aluminum casting plant, copper casting plant and so on.

Advantages

Electrical control cabinets

Fully functional, safe and reliable.

Plc touch screen

Automated programs make operation.

Discharging port

Easier for finished products to be discharged.

Coolant collecting bin

Collection of coolant extruded from the raw material.

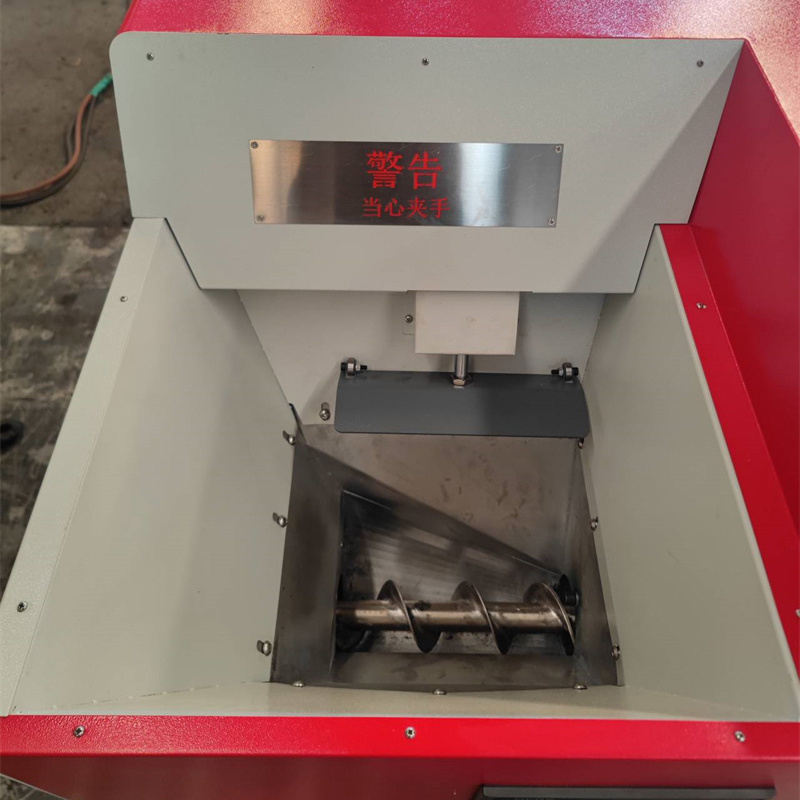

Auger infeed

Not easy to arch,not easy to punch the material.

Cooling fans

Avoid overheating of the machine which affects its service life.

Product Paramenters

|

Small Metal Chip/Shavings/Powder Briquetting Machine

|

|

|

|

Applicable Materials

|

Copper, ALLOY, Aluminum, Carbon Steel, Stainless Steel

|

|

|

Product Features

|

Compact, Easy to use, Fully automatic hydraulic

|

|

|

Main Cylinder Press

|

500KN

|

|

|

Press Block Size

|

70*20-50mm

|

|

|

Feeding Hopper Inlet Size

|

530*490

|

|

|

Hopper Capacity

|

50L

|

|

|

Model Number

|

Y83-50

|

|

The mini metal scrap briquetting machine has a number of features that make it a great choice for metal scrap recycling. The machine is able to compress a variety of metal scrap materials, including aluminum, copper, iron, and steel. The machine also has a high compression ratio, which means that it can create briquettes that are very dense and strong. This makes the briquettes easier to handle and transport, and it also increases their value.

Hot Searches