- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5400*5200*2600 (mm)

-

Weight (T):

-

12

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Nominal Pressure:

-

300KN

-

Punching Times:

-

800 h.p.m

-

Max. Punching Diameter:

-

88.9 mm

-

Clamps Structure:

-

Full floating type

-

Mould Structure:

-

85 series long oriented internationally type

-

CNC System:

-

FANUC-OI-PF

-

Weight:

-

about 12T

-

Power(W):

-

20KW

-

Nominal Force (kN):

-

400

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Xiang Star

-

Voltage:

-

380V/50HZ/3P As per customer's

-

Dimension(L*W*H):

-

5400*5200*2600 (mm)

-

Weight (T):

-

12

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Nominal Pressure:

-

300KN

-

Punching Times:

-

800 h.p.m

-

Max. Punching Diameter:

-

88.9 mm

-

Clamps Structure:

-

Full floating type

-

Mould Structure:

-

85 series long oriented internationally type

-

CNC System:

-

FANUC-OI-PF

-

Weight:

-

about 12T

-

Power(W):

-

20KW

-

Nominal Force (kN):

-

400

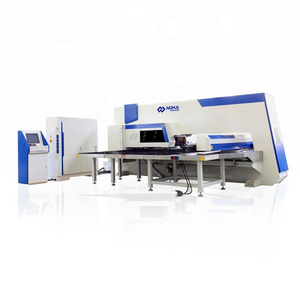

China high precision hydraulic cnc turret punch press

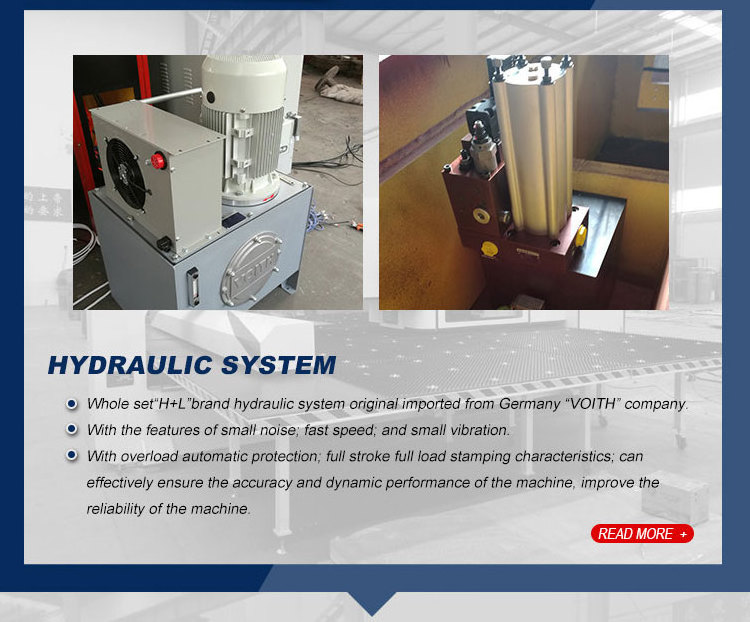

C losed hydraulic CNC turret punching m achine by the programming software (or manual) processing program, by the servo feeding mechanism send the plate to the required processing position, at the same time by the dies selection system select the appropriate die from the turret, then by the hydraulic power system according to the punching procedure, automatic completion of the work piece processing.

|

Name |

Parameters |

Unit |

Remark |

|

|

1 |

Nominal Pressure |

300 |

KN |

30(T) |

|

2 |

Rack Structure |

“O” |

|

closed |

|

3 |

Turret structure |

Thick |

mm |

Up:80/down:70 |

|

4 |

Mold structure |

85 series long oriented |

|

Internationally general type |

|

5 |

Clamp structure / number |

Full floating type |

sets |

2 |

|

6 |

Auto-index numbers |

|

sets |

2 (optional) |

|

7 |

Auto-index transmission mode |

|

|

Turbine and worm |

|

8 |

Number of controlled axes |

3/4(X/Y/T/C) |

axes |

Auto-index (optional) |

|

9 |

Repositioning cylinder |

2 |

sets |

|

|

10 |

Countertop structure |

Brush\universal ball mixed |

|

|

|

11 |

Turret station distribution |

A\B\C\D |

|

standard |

|

12 |

Punching accuracy |

±0.1 |

mm |

|

|

13 |

Repeat positioning accuracy |

±0.02 |

mm |

|

|

14 |

Throat depth |

1280 |

mm |

|

|

15 |

Punch stroke |

40 |

mm |

|

|

16 |

Max. punching frequency |

800 |

t/min |

|

|

17 |

Max. processing plate size |

2500/5000*1250 |

mm |

Secondary positioning |

|

18 |

Max. processing plate thickness |

6 |

mm |

|

|

19 |

Max. plate feeding speed |

60 |

m/min |

|

|

20 |

Max. diameter (once punched) |

88.9 |

mm |

|

|

21 |

Max. work piece weight |

150 |

kg |

|

|

22 |

Turret rotary speed |

30 |

r.p.M |

|

|

23 |

Main motor power |

11 |

KW |

|

|

24 |

Gas consumption |

0.15 |

m³/min |

|

|

25 |

Gas Pressure |

0.6 |

MPa |

|

|

26 |

Dimension (L*W*H) |

5400*5200*2600 |

mm |

|

|

27 |

Weight |

≈12 |

T |

|

|

28 |

CNC system |

FANUC OI-PD |

||

|

29 |

Programming software |

CNCKAD (genuine ) |

||