- Product Details

- {{item.text}}

Quick Details

-

Item name:

-

for FIAT 128 Punto GT 1.4L crankshaft

-

MOQ:

-

3 Pieces

-

Heat Treatment:

-

Ionitriding

-

The Journal Nitride Hardness Depth:

-

≤0.3mm

-

Balance Weight:

-

1g.cm

-

Logo Printing:

-

Available

-

Custom Services:

-

Available

-

Packing:

-

Neutral Packing

Quick Details

-

Place of Origin:

-

China

-

Application:

-

Crankshaft for FIAT 128 Punto GT 1.4L

-

Material:

-

Billet 4340 steel

-

Item name:

-

for FIAT 128 Punto GT 1.4L crankshaft

-

MOQ:

-

3 Pieces

-

Heat Treatment:

-

Ionitriding

-

The Journal Nitride Hardness Depth:

-

≤0.3mm

-

Balance Weight:

-

1g.cm

-

Logo Printing:

-

Available

-

Custom Services:

-

Available

-

Packing:

-

Neutral Packing

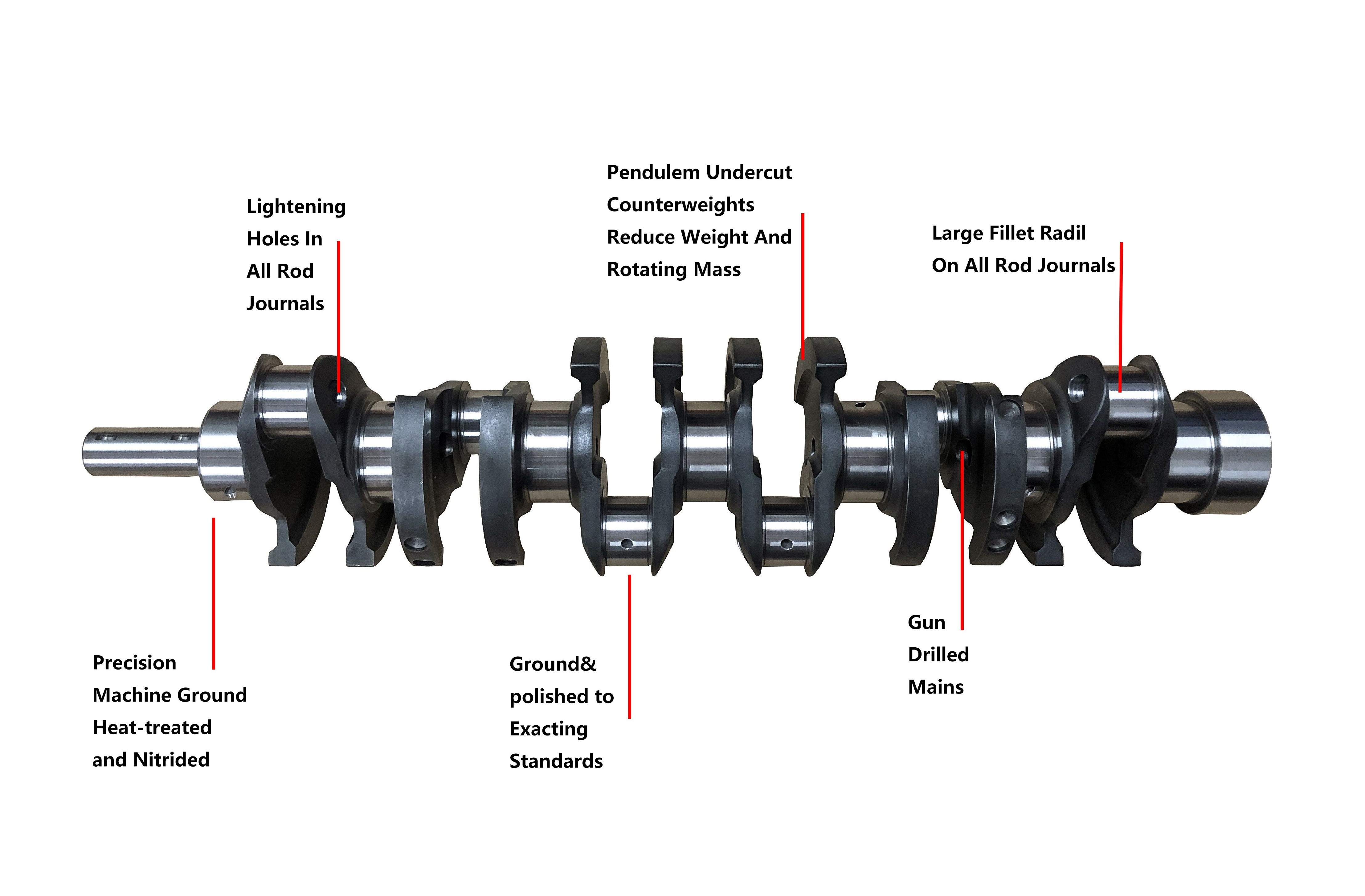

67.4mm stroker Custom Billet 4340 steel crank for Fiat 128 Punto GT 1.4L crankshaft

Counterweights

Counterweights are necessary to offset the forces of the reciprocating components as the crankshaft spins. The most common is knife-edge and Pendulum Undercut counterweights.

Also, different design could be provided according to your needs.

Specifications

| Brand:Adracing | |

| Application(s) | For FIAT 128 Punto GT 1.4L Crankshaft |

| Material | Billet 4340 Steel |

| Stroker | custom |

| Main Journal Diameter | **mm |

| Rod Journal Diameter | **mm |

Technical Features

- Full CNC Machining

- Various treatments are employed to toughen crankshafts for their severe-duty environment. They include heat treatments, hardening techniques, and severe-cold cryogenic treatments to stabilize the metal.

- Heating treatment:HRC34-38

- Nitriding could be done. Its primary benefit is the improvement in impact and resistance to wear. It treats the crank evenly and imparts a surface tension that increases fatigue life by 18%-20%.

- Micro-polishing for longer bearing life

- Peening treatment will be done after balance weight

-

magnetic flaw detecting will be done according to standard JB/76729-93

Essencial Features

Racing crankshafts incorporate many of the essential features shown here to ensure

maximum durability and top performance.

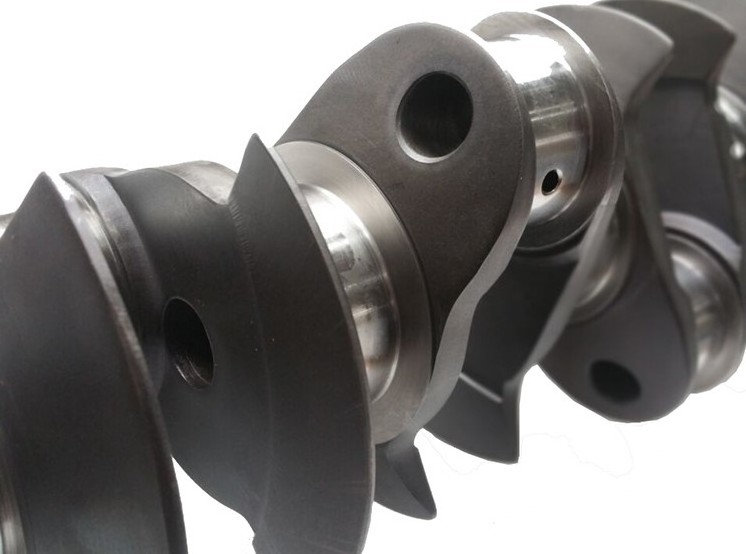

Drilled crankpins are the most effective way of reducing rotational inertia in a racing

crankshaft without affecting the overall strength of individual crankpins.

Gun-drilled mains are also used to lighten a racing crankshaft.

Conventional practice incorporates oiling holes in the rod journals that are chamfered to ease

the flow of oil onto the bearing.

Note the generous fillet radius on rod journal. The radius spreads the load and removes a common point of stress fractures.

Processing

A billet crank begins with a solid billet of material weighing several hundred pounds. The setup and programming time for this procedure is lengthy and expensive.

The machining process for a billet crank is long and precise, but the result is a superior crankshaft with uninterrupted grain structure and maximum strength.

Package

Custom Service

- Our main business is to supply customized service

- we supply customized service based on your sample or drawing

- Price can be estimated if you can send Stroke--rod journal--rod journal width--main journal--main journal width--total length--fan plate bore--width between fan plate bore and photo

Delivery Time

- If the goods are in stock,the delivery time is 7 -10 days

- If the goods are not in stock,the delivery time is 80-90 days

Contact Us