- Product Details

- {{item.text}}

Quick Details

-

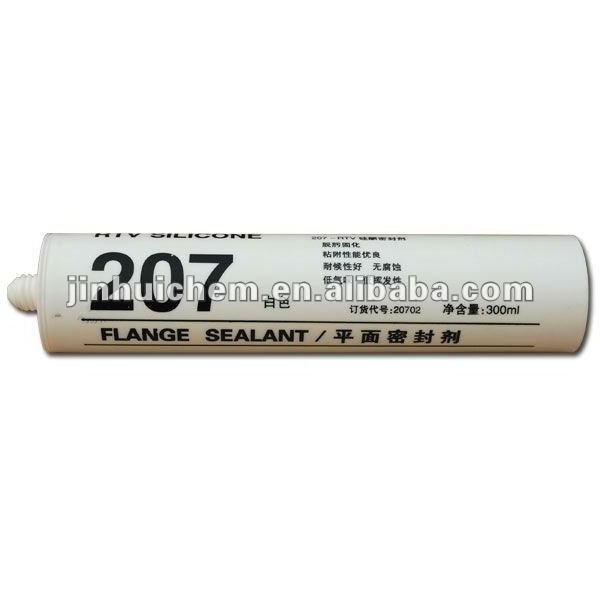

Brand Name:

-

JinHui

-

Model Number:

-

JH207

-

Type:

-

paste

-

color:

-

white

-

Viscosity:

-

paste

-

Tensile StrengthMPa:

-

1.7

-

Elogation(%):

-

400

-

Hardness(Short A):

-

48

-

Temperature(℃):

-

-60~230

Quick Details

-

CAS No.:

-

Mixture

-

Other Names:

-

RTV silicon sealants

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JinHui

-

Model Number:

-

JH207

-

Type:

-

paste

-

color:

-

white

-

Viscosity:

-

paste

-

Tensile StrengthMPa:

-

1.7

-

Elogation(%):

-

400

-

Hardness(Short A):

-

48

-

Temperature(℃):

-

-60~230

JinHui silicone flange sealants are suitable for large gap applications and stamped metal assemblies where falnge flexing occur. Such as transmission pans, oil pans and various covers etc..

|

Appearance (uncured) |

White paste |

|

Chemical Type |

Oxime silicone |

|

Components |

One component |

|

Strength |

Low |

|

Viscosity |

Thixotropic paste |

|

Cure |

Room temperature vulcanizing (RTV) |

|

Application |

Flange sealing |

Typical application

JH207 is designed to give outstanding performance in typical automotive gasketing applications ,it can fill gaps up to 6mm.It is excellent adhesion and weather resistance.

Typical properties of uncured material

|

Gravity @25°C |

1.2 — 1.4 |

|

Viscosity, 25°C, mPa•s (cP): |

Paste |

|

Tack free (min) |

≤30 |

|

Solid all-time (2mm) |

24hr |

|

Extrusion rates (g/min) |

≥100 |

|

Gap fill (mm) |

6 |

Typical properties of cured material (Low carbonate grit blasted steel, @22°C,after 24hr full cured)

|

Temperature (°C) |

-53 —210 |

|

Shear strength (N.m) |

≥1.5 |

|

Sealing time |

Immediately sealed |

|

Shore Hardness(A) |

30 — 40 |

|

Elongation % |

≥300 |

Cure Properties

JH207 is moisture curing. It begin to cure after the product is exposed to the atmosphere. Excess cured material can be removed with a knife or single edge razor blade.

Cure speed

The JH207 speed of curing can be slowed down when the temperature is lower than 15°C

Usage

l For best results, please clean all surfaces with cleaning solvent JH755 and allow to dry.

l Apply product JH207 on one of the two bonding surfaces, and form a continuous closed strip.

l Assemble the bonding surfaces. Please note that moving is forbidden.

Storage

l It should be kept in an unopened container in a cool and dry location. Optimal storage: 8°C to 21°C. Storage below 8°C or greater than 28°C cam adversely affect product properties.

l Material removed from containers may be contaminated during use. Do not return product to the original container.

l Keep away from children.