- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

500kg

-

Size:

-

1000mmx1100mmx1200mm

-

Power:

-

1.47kw, 380V/customized

-

Weight (KG):

-

500 kg

-

Application:

-

Leather/Municipal water and Industrial water

-

Type:

-

Water Filter Parts

-

Color:

-

Grey

-

Function:

-

Sludge dewatering

-

Control:

-

PLC/Relay control

-

Outlet moisture:

-

75%-80%

-

Capacity:

-

0.5-32M3/H

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

TOP

-

Material:

-

pallet, Stainless Steel

-

Weight:

-

500kg

-

Size:

-

1000mmx1100mmx1200mm

-

Power:

-

1.47kw, 380V/customized

-

Weight (KG):

-

500 kg

-

Application:

-

Leather/Municipal water and Industrial water

-

Type:

-

Water Filter Parts

-

Color:

-

Grey

-

Function:

-

Sludge dewatering

-

Control:

-

PLC/Relay control

-

Outlet moisture:

-

75%-80%

-

Capacity:

-

0.5-32M3/H

-

Certification:

-

ISO

Hot Sell Screw Press Sludge Dewatering Machine

Hot selling Screw Press for SBR

TPDL volute screw sludge dewatering machine is a new technology of Sludge Dewatering Machine(Hereinafter referred as TPDL) which belongs to the screw press, can replace the traditional filter press like belt press and frame press. It's clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction.

Screw Press Usage

•Municipal & Domestic

•Tannery•Paper & Pulp•Dyeing & Printing

•Food & Beverage•Dairy•Agricultural•Slaughter & Farming

•Pharmaceutical & Petrochemical

Hot selling Screw Press for SBR

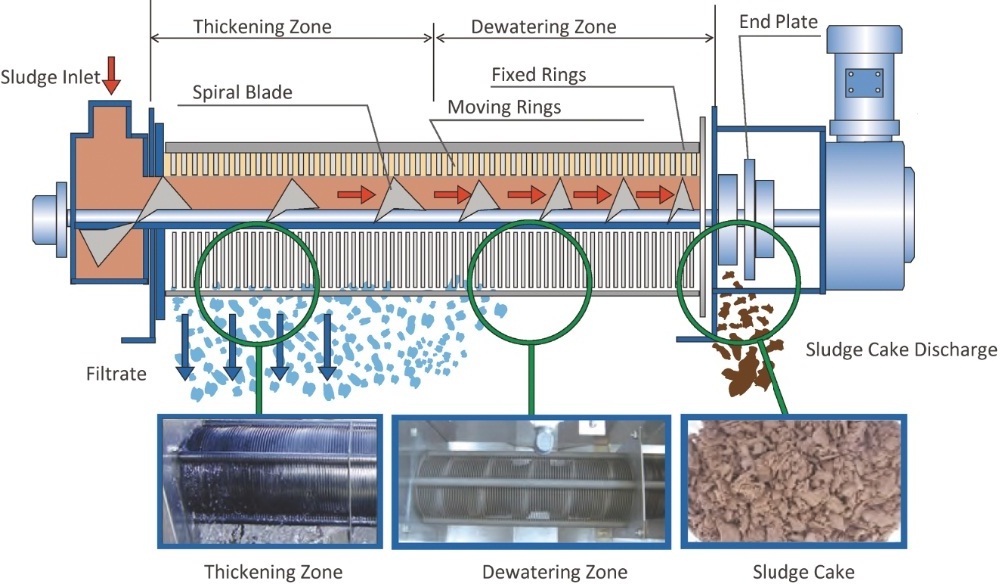

Screw Press Working principle

The wastewater is pushed into the dewatering machine.The sludge will move to the sludge cake outlet under the pressure of the helical aixs blades. Becuse the gap among the helical blades become narrower,so the sludge bear heavier pressure and began to dewatering under the pressure. The water comes out from the space between fixed and moving plates.

Hot selling Screw Press for SBR

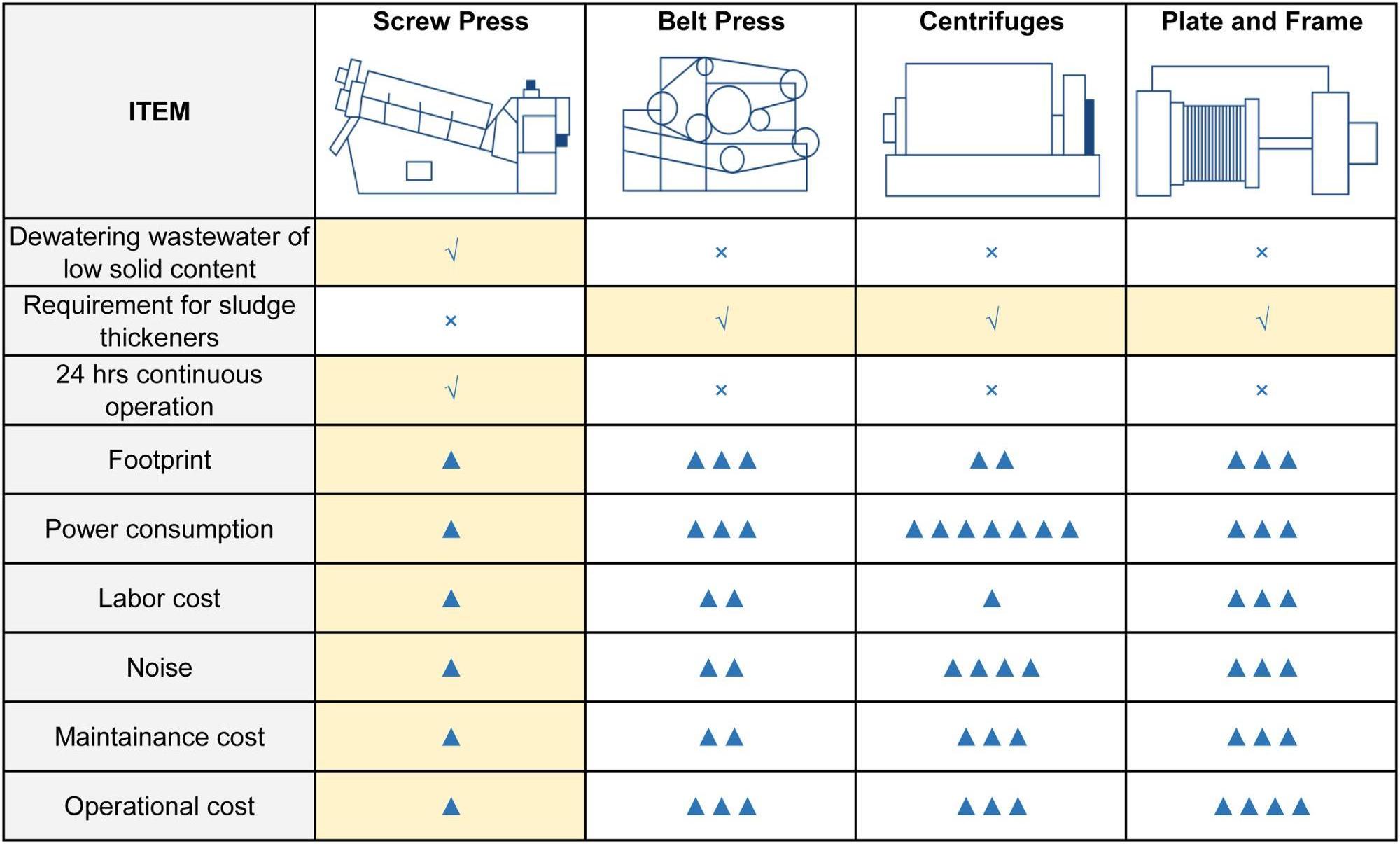

Screw Press Advantages

1. Low operation cost: below 40% of belt press and 20% of centrifuge.

2. Power-saving: less than 5% of centrifuge

3. Water-saving: less than 0.1% of belt filter press.

4. Saving drugs: saving around 60%.

5. Compact: saving more than 60% of the investment for dehydration room.

6. Non-clogging: processing the fats & oils and fiber sludge perfectly.

Hot selling Screw Press for SBR

Screw press spare part

Hot selling Screw Press for SBR

Screw Press Process flow chart

Hot selling Screw Press for SBR

Hot selling Screw Press for SBR

With our consistent effort, our machinery is supplied to more than 30 countries

Hot selling Screw Press for SBR

Wooden pallet or standard export wooden box as per customers' requirement.

Hot selling Screw Press for SBR

Hot selling Screw Press for SBR

Top machinery, founded in 2002, specialized manufacture wastewater treatment equipment and sludge dewatering machine, like screw type sludge dewatering machine, decanter centrifuge, brushing/scraping self-cleaning filter, automatic back-flushing filter, Bernoulli filter, electrocoagulation, inward/outward water micro filter, bar screen, etc. With our consistent effort, high quality, competitive price and good after-service, our machines are supplied to more than 30 countries with very good feedback.

Hot selling Screw Press for SBR