- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Zhengzhou Sinoma

-

Dimension(L*W*H):

-

Depending on Model

-

Weight:

-

10000 KG, 4 - 500tons

-

Output size:

-

0.074-0.4 mm

-

Max feeding size:

-

≤ 25 mm

-

Installation:

-

Under Technical Guidance

-

Color:

-

Customer Requirement

-

Usage:

-

Grinding Powder

-

Spare parts supplying:

-

Available

-

Factory Visit:

-

Welcome

-

Quality:

-

Top level

-

Advantages:

-

Long Service Life

Quick Details

-

Marketing Type:

-

New Product 2024

-

Capacity(t/h):

-

0.5 - 600t/h (Depending on model)

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhengzhou Sinoma

-

Dimension(L*W*H):

-

Depending on Model

-

Weight:

-

10000 KG, 4 - 500tons

-

Output size:

-

0.074-0.4 mm

-

Max feeding size:

-

≤ 25 mm

-

Installation:

-

Under Technical Guidance

-

Color:

-

Customer Requirement

-

Usage:

-

Grinding Powder

-

Spare parts supplying:

-

Available

-

Factory Visit:

-

Welcome

-

Quality:

-

Top level

-

Advantages:

-

Long Service Life

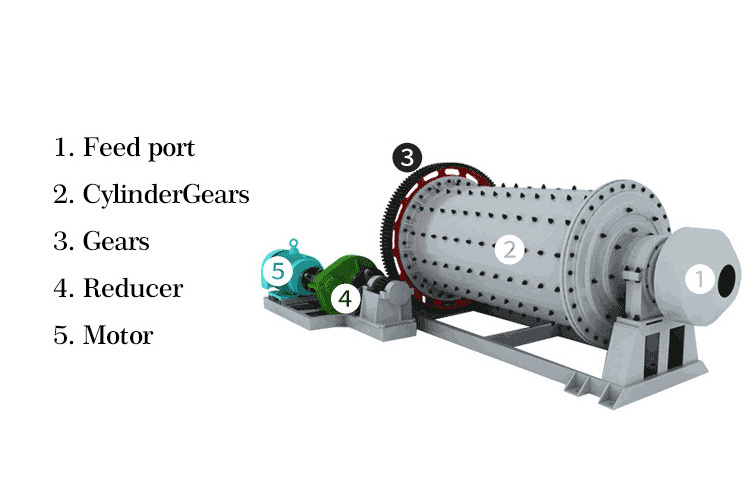

Product Description

Ball Mill

is a widely used grinding equipment, which grinds materials through the collision between materials, or the collision and friction between materials and the object ,the material is ground to the required particle size. It is widely used in the grinding process of mining, metallurgy, building materials, chemical industry and other industries for various ores, coal powder, ceramic raw materials, etc.

Details Images

Features:

1. High efficiency, it grinds materials to the required size in a short period of time.

2. F

ine and even final material size. The big and small balls inside the machine makes the finished size fine and even.

3. Simple structure, ball mill's structure is compact and strong, simple internal structure makes it easy to operate and maintain.

4. Wide range of applications, it's widely used in mining, gold smelting, chemical industry, building materials, pharmaceuticals and other fields.

5. Stable operation. There is no inertial impact, which reduces the frequency of machine downtime and maintenance and improves production efficiency.

Product Paramenters

|

Model

|

Ball Weight

(t)

|

Max Input Size

(mm)

|

Output Size

(mm)

|

Capacity

(t/h)

|

Power

(kw)

|

Total Weight

(t)

|

|

Ф900*1800

|

1.5

|

20

|

0.075-0.89

|

0.65-2

|

18.5

|

5.85

|

|

Ф900*3000

|

2.7

|

20

|

0.075-0.89

|

1.1-3.5

|

22

|

6.98

|

|

Ф1200*2400

|

3

|

25

|

0.075-0.6

|

1.5-4.8

|

30

|

13.6

|

|

Ф1200*3000

|

3.5

|

25

|

0.074-0.4

|

1.6-5

|

37

|

14.3

|

|

Ф1200*4500

|

5

|

25

|

0.074-0.4

|

1.6-5.8

|

55

|

15.6

|

|

Ф1500*3000

|

7.5

|

25

|

0.074-0.4

|

2-5

|

75

|

19.5

|

|

Ф1500*4500

|

11

|

25

|

0.074-0.4

|

3-6

|

110

|

22

|

|

Ф1500*5700

|

12

|

25

|

0.074-0.4

|

3.5-6

|

130

|

25.8

|

|

Ф1830*3000

|

11

|

25

|

0.074-0.4

|

4-10

|

130

|

34.5

|

|

Ф1830*4500

|

15

|

25

|

0.074-0.4

|

4.5-12

|

155

|

38

|

|

Ф1830*6400

|

21

|

25

|

0.074-0.4

|

6.5-15

|

210

|

43

|

|

Ф1830*7000

|

23

|

25

|

0.074-0.4

|

7.5-17

|

245

|

43.8

|

|

Ф2100*3000

|

15

|

25

|

0.074-0.4

|

6.5-36

|

155

|

45

|

|

Ф2100*4500

|

24

|

25

|

0.074-0.4

|

8-43

|

245

|

56

|

|

Ф2100*7000

|

26

|

25

|

0.074-0.4

|

12-48

|

280

|

59.5

|

|

Ф2200*4500

|

27

|

25

|

0.074-0.4

|

9-45

|

280

|

54.5

|

|

Ф2200*6500

|

35

|

25

|

0.074-0.4

|

14-26

|

380

|

61

|

|

Ф2200*7000

|

35

|

25

|

0.074-0.4

|

15-28

|

380

|

62.5

|

|

Ф2200*7500

|

35

|

25

|

0.074-0.4

|

15-30

|

380

|

64.8

|

|

Ф2400*3000

|

23

|

25

|

0.074-0.4

|

7-50

|

245

|

58

|

|

Ф2400*4500

|

30

|

25

|

0.074-0.4

|

8.5-60

|

320

|

72

|

|

Ф2700*4000

|

40

|

25

|

0.074-0.4

|

22-80

|

380

|

95

|

|

Ф2700*4500

|

48

|

25

|

0.074-0.4

|

26-90

|

480

|

102

|

|

Ф3200*4500

|

65

|

25

|

0.074-0.4

|

30-120

|

630

|

149

|

|

Ф3600*4500

|

90

|

25

|

0.074-0.4

|

35-160

|

850

|

169

|

|

Ф3600*6000

|

110

|

25

|

0.074-0.4

|

40-200

|

1250

|

198

|

|

Ф3600*8500

|

131

|

25

|

0.074-0.4

|

45.8-256

|

1800

|

260

|

|

Ф4000*5000

|

121

|

25

|

0.074-0.4

|

45-208

|

1500

|

230

|

|

Ф4000*6000

|

146

|

25

|

0.074-0.4

|

65-248

|

1600

|

242

|

|

Ф4000*6700

|

149

|

25

|

0.074-0.4

|

75-252

|

1800

|

249

|

|

Ф4500*6400

|

172

|

25

|

0.074-0.4

|

84-306

|

2000

|

280

|

|

Ф5030*6400

|

216

|

25

|

0.074-0.4

|

98-386

|

2500

|

320

|

|

Ф5030*8300

|

266

|

25

|

0.074-0.4

|

118-500

|

3300

|

403

|

|

Ф5500*8500

|

338

|

25

|

0.074-0.4

|

148-615

|

4500

|

525

|

* Note: The capacity may vary with different materials and feeding sizes. Technical parameters are subject to change without notice.

Application Areas&Materials

Application:

1. Grinding iron ore powder, non-ferrous metal ore powder in metallurgical industry;

2. Grinding various coatings, pigments and other fine chemical materials into powder in chemical industry;

3. Grinding powder for cement, glass and other building materials powder in building materials industry;

4. Grinding ceramic raw materials in ceramic industry.

2. Grinding various coatings, pigments and other fine chemical materials into powder in chemical industry;

3. Grinding powder for cement, glass and other building materials powder in building materials industry;

4. Grinding ceramic raw materials in ceramic industry.

Suitable for grinding more than 100 kinds of materials , such as iron ore, copper ore, golden ore, river pebbles, kaolin, limestone, dolomite, granite, marble, basalt, coal,

sandstone, shale,

etc.

Packing & Delivery

Hot Searches