- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JinLuli

-

Model Number:

-

Poplar Veneer

-

Size:

-

840*1270mm/640*1270mm

-

Thickness:

-

1.7mm/2.0mm

-

Usage:

-

Plywood

-

Material:

-

Poplar Wood/Pine Wood

Quick Details

-

Technics:

-

Rotary Cut

-

Veneer Type:

-

Natural Wood Veneer

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

JinLuli

-

Model Number:

-

Poplar Veneer

-

Size:

-

840*1270mm/640*1270mm

-

Thickness:

-

1.7mm/2.0mm

-

Usage:

-

Plywood

-

Material:

-

Poplar Wood/Pine Wood

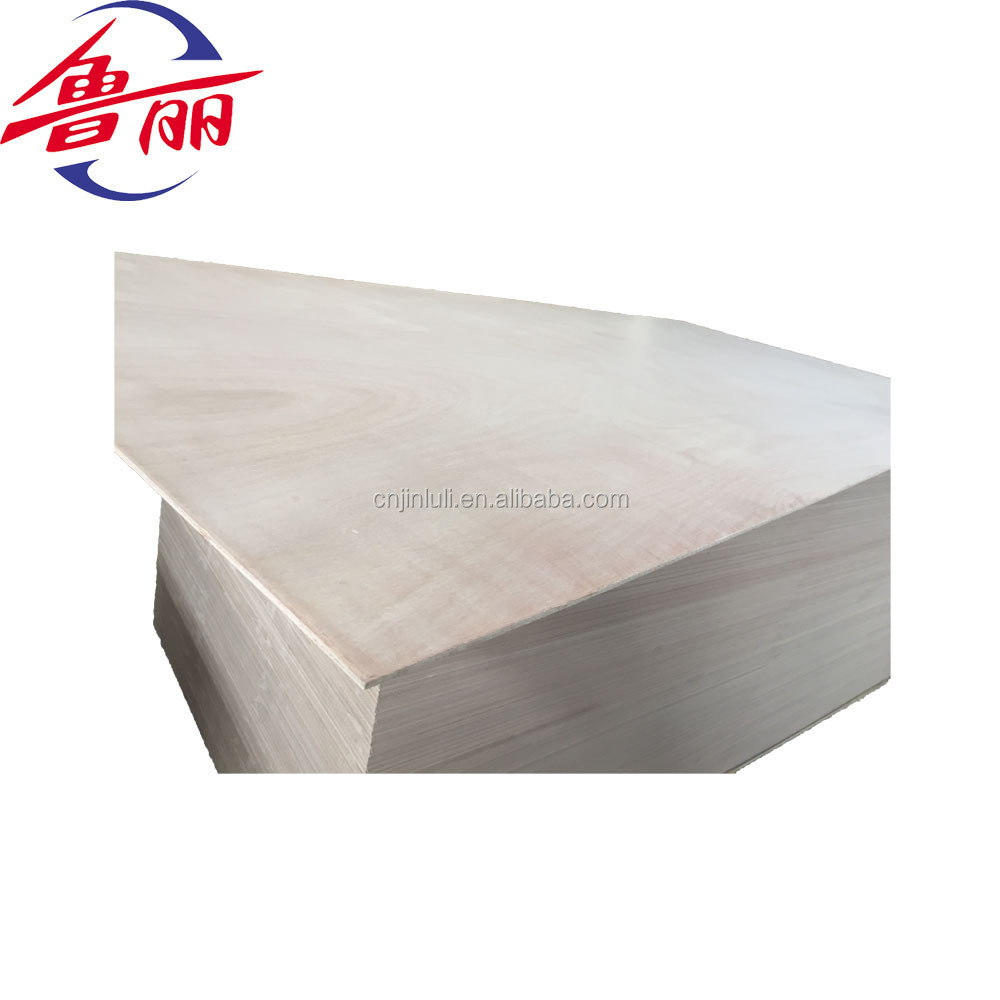

high quality 840*1270mm poplar core veneer

|

NATURE VENEER |

GURJAN,PLB,OKOUME,BINTANGOR, ALDER, POPLAR,BEECH, |

|

RECOMPOSED VENEER |

RECON GURJAN/KERUING, RECON TEAK,RECON WALNUT, RECON SAPELLI,RECON POPLAR, |

|

SIZE |

1270X2520X0.3MM-0.5MM |

|

MOISTURE CONTENT |

BELOW 14% |

|

USAGE |

1.FOR PLYWOOD SURFACE 2.USED FOR DOORS,FLOORING,WALL PANELS AND SO ON. |

|

PACKING |

STANDARD PALLETS PACKING |

|

LOADING PORT |

QINGDAO PORT |

|

PAYMENT |

T/T OR L/C AT SIGHT |

|

LATEST DATE OF SHIPMENT: |

35 DAYS AFTER WE RECEIVE L/C |

PRODUCTION PROCESS:

Log Selection

EV is generally produced from Chinese Poplar logs, grown locally either by local co-operatives,

or in registered plantation areas. The light natural colour and soft grain definition of Poplar makes it wellsuited to the production of EV. The process of converting timber into EV starts with the selection of logs, following which they are bought to the mill for processing. The timber is trimmed, sawn to length and debarked. The logs are now ready to be peeled.

Peeling of the Logs

The logs are mounted onto a giant lathe. Within minutes the logs are peeled into rotary veneers. This is achieved by pressing a rotating log towards a large blade, thinly peeling a continuous sheet of veneer off the log. The veneer is dried, stacked and then graded. It is now ready to be dyed.

Drying

EV veneers can be dryed to a consistent colour to suit the market requirement. The raw veneer leaves are stacked into a stainless steel cage. Once completely loaded, the stainless steel cage is immersed into a pressurized, heated vat that is filled with water soluble dry. This system ensures that each leaf is given the correct amount of time to allow the dry to completely penetrate each individual leaf of veneer. Once the desired colour has been achieved, the leaves are unloaded from the vat, dried and given a final inspection before going to the gluing stage.

1.Your inquiry related to our product and price will be replied within 24 hours.

2.Free sample are available.

3.Welltrained and experienced staff are to answer all your inquiies in English.

4.Experience: a specialized manufacturer for wood products since 1985.

5.Export market: USA, Asia, Europe, Middle east, Africa and so on.

If you need wood products, please contact us, we will provide you the most satisfied products.