1. Significantly better resistance to ozone and weathering than usual NBR.

2、Improved flame resistance compared to normal NBR.

3, solvent resistance, oil resistance, chemical resistance and other properties than the usual nitrile rubber has improved.

4. Improved processing properties. Compared with NBR, the extrusion speed is accelerated, the extrusion outlet expansion is reduced, the surface is bright and clean, and the processing and appearance quality of calendered and moulded products are improved.

5. Can be coloured at will to produce bright coloured products

6、Improved low temperature characteristics, oil resistance and elongation compared to the usual PVC.

7. Significant reduction in fuel transmission rate.

8、Improved abrasion resistance and tear strength.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

NV3380

-

Product name:

-

NBR PVC rubber material

-

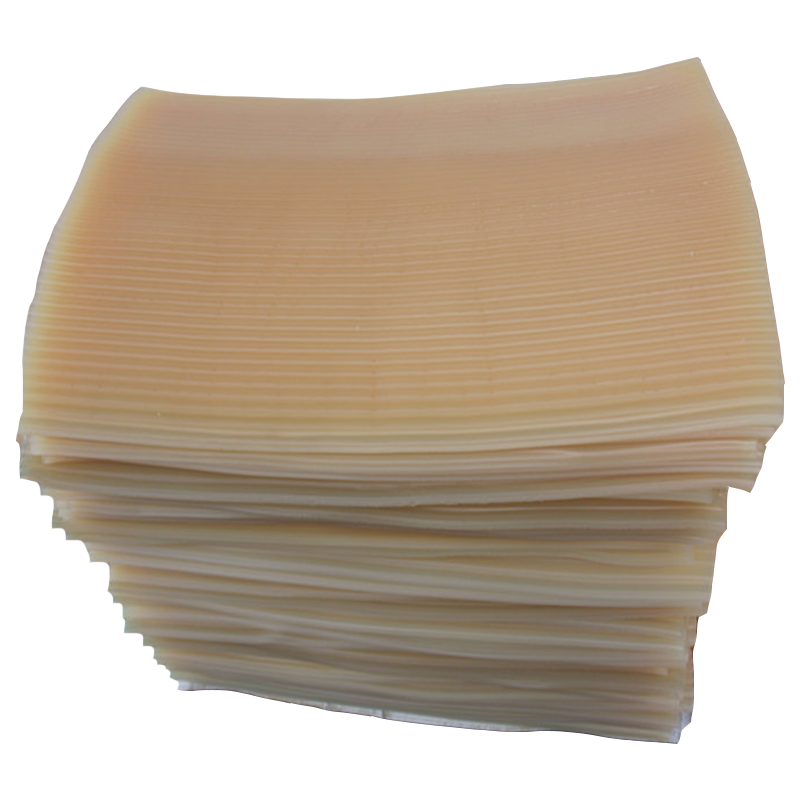

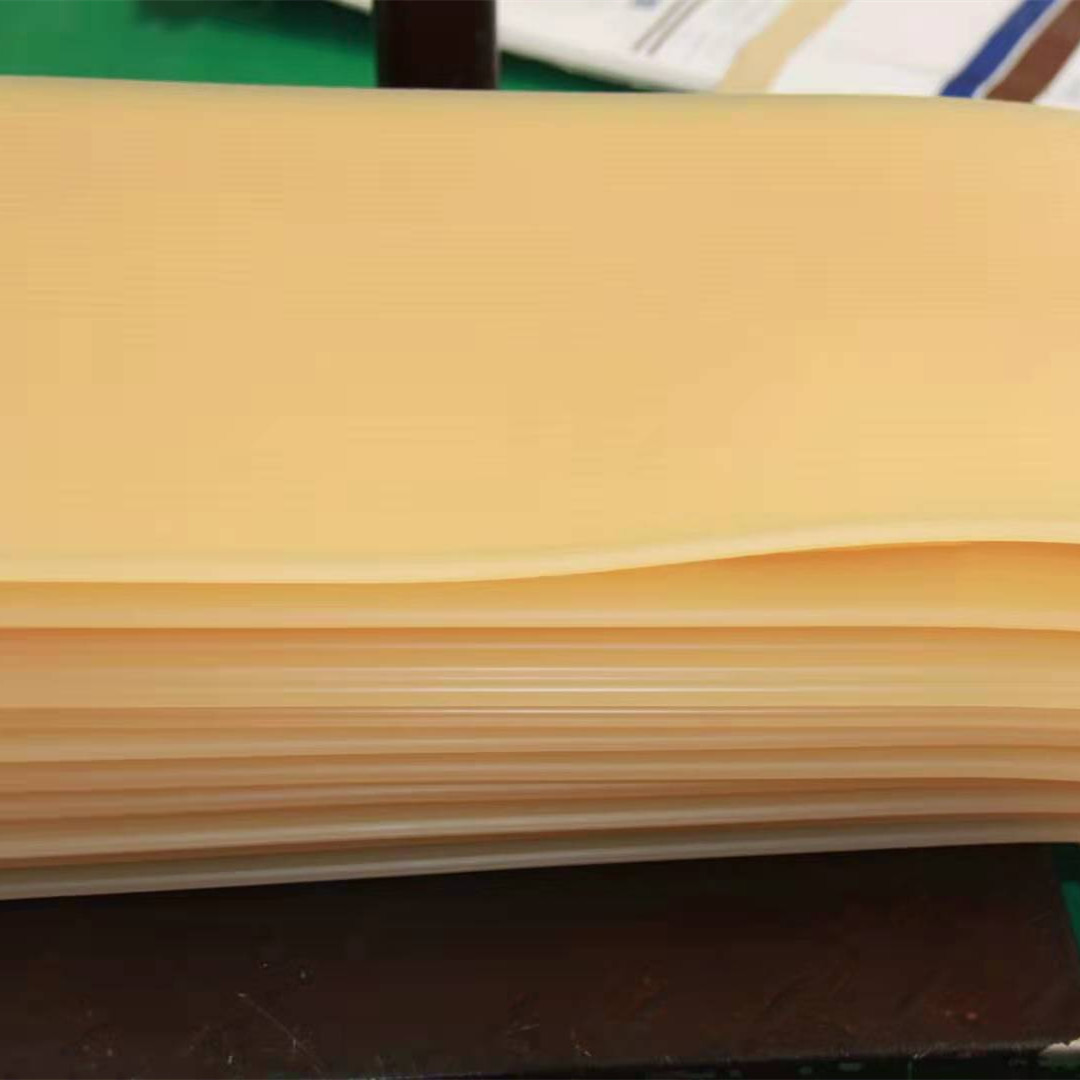

Appearance:

-

Yellow rubber sheet

-

ACN content %:

-

25±2

-

NBR/PVC:

-

70/30

-

Mooney viscosity:

-

80±5

-

Density g/cm3:

-

1.02-1.10

-

Advantage:

-

Excellent flame and oil resistance

-

Isolating agent %:

-

6-8

-

Packing:

-

15-20kg/bag

-

Sample:

-

free

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Jiansheng technology

-

Model Number:

-

NV3380

-

Product name:

-

NBR PVC rubber material

-

Appearance:

-

Yellow rubber sheet

-

ACN content %:

-

25±2

-

NBR/PVC:

-

70/30

-

Mooney viscosity:

-

80±5

-

Density g/cm3:

-

1.02-1.10

-

Advantage:

-

Excellent flame and oil resistance

-

Isolating agent %:

-

6-8

-

Packing:

-

15-20kg/bag

-

Sample:

-

free

Products Description

Product Description

:

The rubber-plastic alloy (NBR/PVC) is a melt blended adhesive of nitrile rubber (NBR) and polyvinyl chloride (PVC). Due to the excellent compatibility of NBR with PVC, the two materials can be blended in any ratio.

This product is a custom product, you can consult customer service before purchase, the final price is subject to processing custom claims!

Product parameters

|

Model

|

ACN content

% |

NBR/PVC

|

Mooney viscosity

ML(1+4)100℃ |

Density

g/cm3 |

Main application

|

|

NV3380

|

25±2

|

70/30

|

80±5

|

1.02-1.10

|

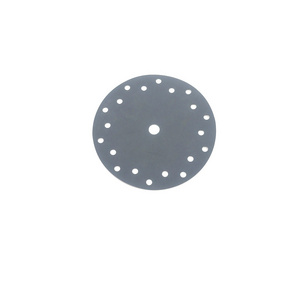

Excellent flame and oil resistance and wear resistance, and suitable for fuel pipes, rubber rollers, conveyor belts, shoe

materials, etc. |

Product advantages

Our Selling Points

Application

Other product parameters

|

Model

|

ACN conten %

|

NBR/PVC

|

Mooney viscosity

ML(1+4)100℃ |

Density

g/cm3 |

Main application

|

|

NV7030H

|

25±2

|

70/30

|

60±5

|

1.02-1.10

|

Excellent comprehensive performance, widely used in rubber hose, tape, rubber roll, dust cover, shoe material and other products.

|

|

NV7030-Ⅱ

|

26±2

|

70/30

|

45±5

|

1.02-1.10

|

Excellent processing performance, mainly used for rubber hose, rubber roll industry.

|

|

NV8020

|

29±2

|

80/20

|

40±5

|

1.02-1.10

|

Excellent physical properties, suitable for rubber pipes, seals, conveyor belts.

|

|

NV3375

|

28±2

|

70/30

|

55±5

|

1.02-1.10

|

Excellent fuel resistance, high tensile strength, suitable for fuel pipe, shaped pipe and other products.

|

|

NV2865

|

28±2

|

70/30

|

55±5

|

1.02-1.10

|

Excellent low temperature, suitable for hose inner glue, shoe material, seal, foam products, etc.

|

|

NV3350

|

22±2

|

70/30

|

40±5

|

1.02-1.10

|

Specially for molded products, Excellent processing performance.

|

|

NV5050

|

29±2

|

50/50

|

45±5

|

1.02-1.10

|

Great oil and abrasion resistance, excellent ozone resistance.

|

|

NV1025

|

20±2

|

70/30

|

15±5

|

1.02-1.10

|

Oil-filled alloy rubber for low hardness products, printing rollers, etc.

|

|

NV1865

|

18±2

|

70/30

|

60±5

|

1.02-1.10

|

Excellent low temperature resistance, good extrusion and calendering technology, mainly used for low temperature resistant

products. |

|

NV7040

|

30±2

|

70/30

|

60±5

|

1.02-1.10

|

Excellent oil resistance, suitable for oil field products, textile accessories, fuel pipes material, shoe materials and other

products. |

|

NV3380

|

25±2

|

70/30

|

80±5

|

1.02-1.10

|

Excellent flame and oil resistance and wear resistance, and suitable for fuel pipes, rubber rollers, conveyor belts, shoe

materials, etc. |

|

NV3345

|

25±2

|

70/30

|

45±5

|

1.02-1.10

|

Excellent comprehensive processing performance, mainly used in the rubber hose and rubber roller industry.

|

Why Choose Us

FAQ

About placing an order

If you need to customize, please consult customer service before placing your order, we will help you answer production questions.

About the manufacturer

The company's production cycle is short and the quality of the goods is guaranteed.

About the quality

We support video and offline factory inspection, we provide samples for you to check.

About the samples

We offer free samples, but you will need to pay for shipping.

About the pictures

All products images are taken in real life.

About after-sales service

We will provide a complete after-sales service and a full online service.

About delivery

Please contact our customer service for specific logistics.

Hot Searches